Get: 124 results / Total 21 pages

Boiler tubes erosion shields protect against wear and corrosion in harsh boiler environments, extending tube life and reducing maintenance costs with durable, custom-fit designs.

Gb 5310 seamless tubes (e.g., 20g, 15mog, 25mng) are heat‑treated, high-strength pipes engineered for high‑pressure boilers, delivering robust mechanical performance, corrosion resistance, and certified quality.

Seamless pipes for oil and gas, power generation, petrochemicals, and construction, offering high strength and corrosion resistance for high-pressure applications.

Stainless steel pipe is one of the more standardized materials resist corrosion due to a minimum 10.5% chromium content.

Non-alloy steel tubes offer excellent durability and corrosion resistance for industrial piping, boilers, and structural applications.

Astm a213 alloy tubes, including grades like t5, t9, t11, t22, and t91, offer excellent corrosion and creep resistance, ideal for high-temperature applications in boilers, superheaters, and heat exchangers.

Bimetal clad pipe is cast with mold vanishing vacuum suction casting cladding process.

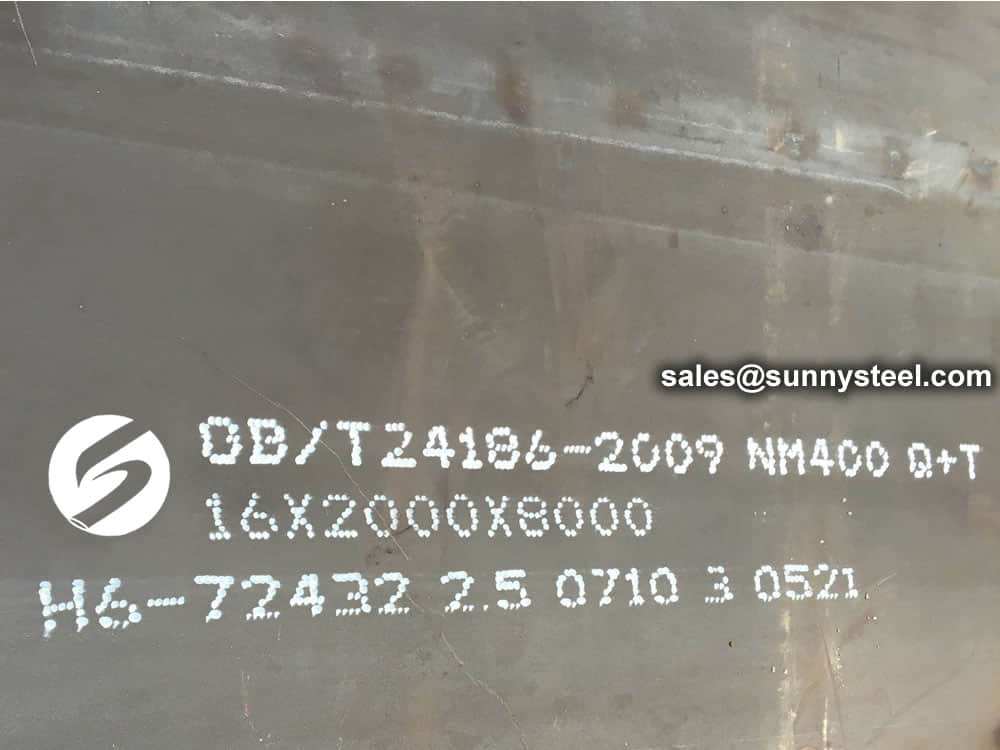

NM400 Steel Plate is a type of wear-resistant steel plate that is commonly used in various industrial applications.

Ceramic tile lined pipes are pipelines that have a ceramic tiles lining layer inside a steel pipe.

The wear resistance of the pulverized coal conveying pipeline of the boiler of the thermal power plant must be designed for leakproof, anti-corrosion, rain-proof, anti-freeze and other factors.