Get: 10 results / Total 2 pages

A pipe tee is also called triplet,three way and 't' pieces and it can be used to either combine or split a fluid flow. tee is a kind of chemical pipe fitting with three ports, one inlet and two outlets; or two inlets and one outlet, t-shaped and y-shaped, with equal and reducer orifices, used in three identical or different pipeline convergence.

Cast basalt lined steel tees deliver exceptional abrasion and corrosion protection at pipeline junctions—ideal for slurry, ash, chemical, and industrial fluid systems.

Ceramic sleeve lined pipe tees provide outstanding wear and corrosion resistance at high-stress junctions, ensuring long service life in abrasive flow systems.

Bimetallic composite pipe tee combines a hard, wear-resistant inner alloy layer with a strong carbon steel outer pipe, providing exceptional durability in abrasive and corrosive pipeline systems.

Our ceramic tile lined pipe tee ensures reliable abrasion resistance and longer life in slurry, ash, and powder transport systems with high turbulence and impact zones.

Rare earth alloy wear resistant explosion proof tee provides superior abrasion and impact resistance with enhanced explosion-proof safety features, ideal for demanding industrial pipeline applications.

Bimetal clad pipe is cast with mold vanishing vacuum suction casting cladding process.

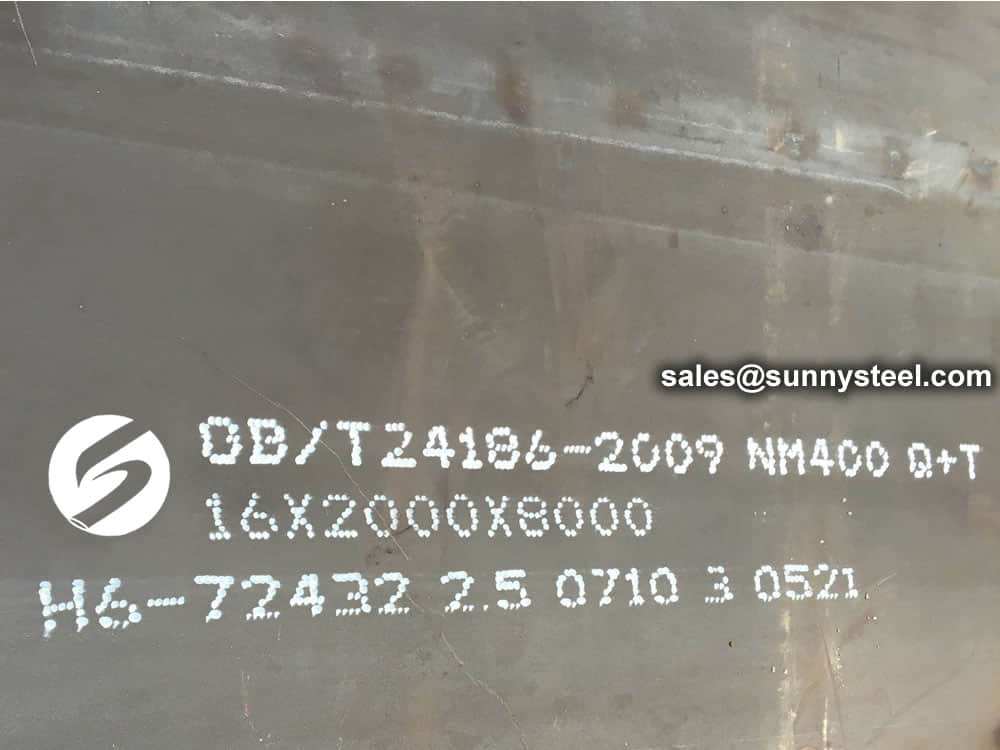

NM400 Steel Plate is a type of wear-resistant steel plate that is commonly used in various industrial applications.

Ceramic tile lined pipes are pipelines that have a ceramic tiles lining layer inside a steel pipe.

The wear resistance of the pulverized coal conveying pipeline of the boiler of the thermal power plant must be designed for leakproof, anti-corrosion, rain-proof, anti-freeze and other factors.