Tag# Basalt Lined Pipe search

Get: 13 results / Total 3 pages

Cast basalt

Categories - is a kind of silicate crystalline material after producingCast basalt pipe adopt magma centrifugal casting molding, then go through the tunnel kiln to annealing, and over a period of open storage to eliminating naturally the residual internal stress of cast basalt pipe

Cast basalt pipe

Categories - Wear And Corrosion Resistant Industrial TransportCast basalt pipes feature high mohs hardness and chemical resistance, delivering long-lasting protection in harsh industrial transport systems handling abrasive or corrosive materials.

Heavy‑Calibre Cast Basalt Lined Pipeline

Product - Industrial Grade ProtectionHeavy-calibre pipelines lined with thick cast basalt deliver exceptional abrasion and corrosion protection for large-scale industrial systems—built for durability and longevity.

Cast Basalt Pipes and Cylinders

Product - Durable Wear-resistant SolutionsHigh-performance cast basalt pipes and cylinders offering superior abrasion, corrosion, and thermal resistance for industrial applications.

Cast Basalt Lined Ash Handling Pipe with Flange & Coupling

Product - Engineered For Tough Ash And Slag Handling In Industrial SystemsCast basalt lined ash handling pipe with flanges and couplings offers superior abrasion and corrosion protection—ideal for high‑wear industrial ash transport systems.

Cast Basalt Lined Pipe & Fittings

Product - Extreme Wear ResistanceComprehensive pipeline solutions with seamless basalt lining and steel integration, designed for maximum durability in abrasive and corrosive environments. cast basalt lined pipes and fittings deliver unmatched abrasion, corrosion, and heat protection with seamless basalt fusion—ideal for slurry, ash, and chemical systems.

搜索

搜索统计

6

产品0

文章Hot products

Bimetal Clad Pipe

Bimetal clad pipe is cast with mold vanishing vacuum suction casting cladding process.

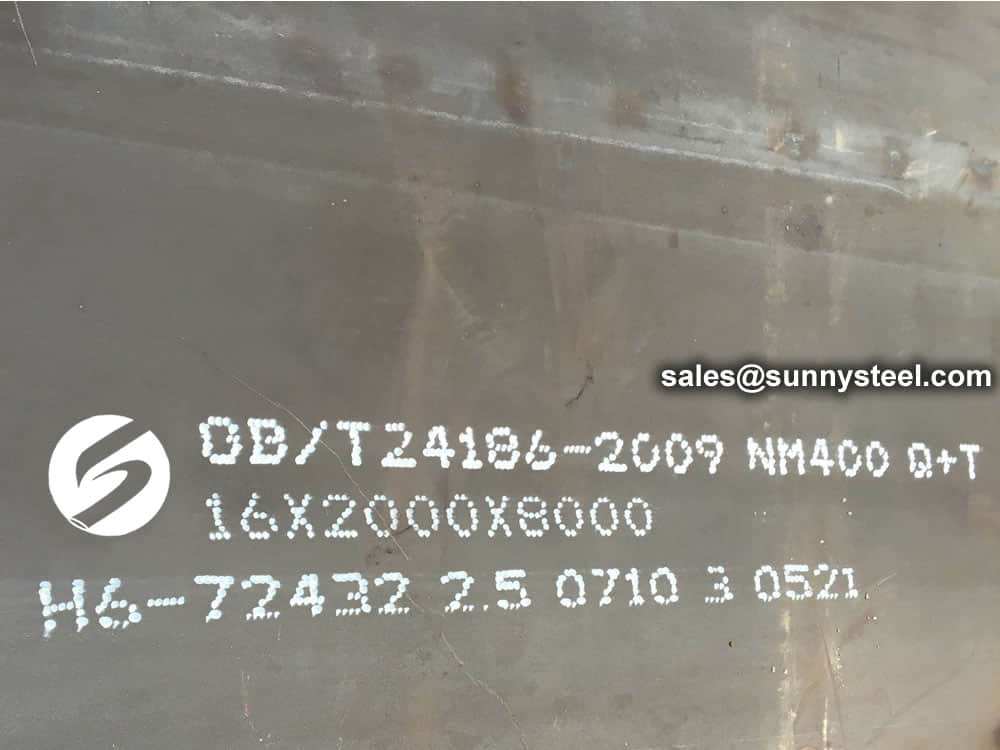

NM400 Steel Plate

NM400 Steel Plate is a type of wear-resistant steel plate that is commonly used in various industrial applications.

Ceramic Tile Lined Pipes

Ceramic tile lined pipes are pipelines that have a ceramic tiles lining layer inside a steel pipe.

Wear-Resistant Pipe Elbow For Boiler Powder Feed

The wear resistance of the pulverized coal conveying pipeline of the boiler of the thermal power plant must be designed for leakproof, anti-corrosion, rain-proof, anti-freeze and other factors.