Get: 7 results / Total 2 pages

Ceramic sleeve lined pipes offer exceptional wear and corrosion resistance, ideal for conveying abrasive materials in mining, power, and chemical industries.

Wear-resistant composite structures deliver long-term protection against abrasion, corrosion, and impact by combining the strengths of ceramics, metals, and polymers in an engineered system.

Straight ceramic-lined pipes combine steel strength with hard ceramic interior to resist wear, corrosion, and heat—ideal for slurry, ash, and abrasive flow systems.

Ceramic tile lined pipe spools provide long-lasting protection against abrasion and chemical attack, making them ideal for transporting slurry, ash, and bulk solids in demanding environments.

Ceramic composite wear resistant elbows offer excellent abrasion protection and durability for high-velocity abrasive media in industrial pipelines.

Ceramic-lined composite pipes offer outstanding wear, corrosion, and heat resistance—perfect for slurry, ash, and chemical transport in heavy-duty industrial systems.

Bimetal clad pipe is cast with mold vanishing vacuum suction casting cladding process.

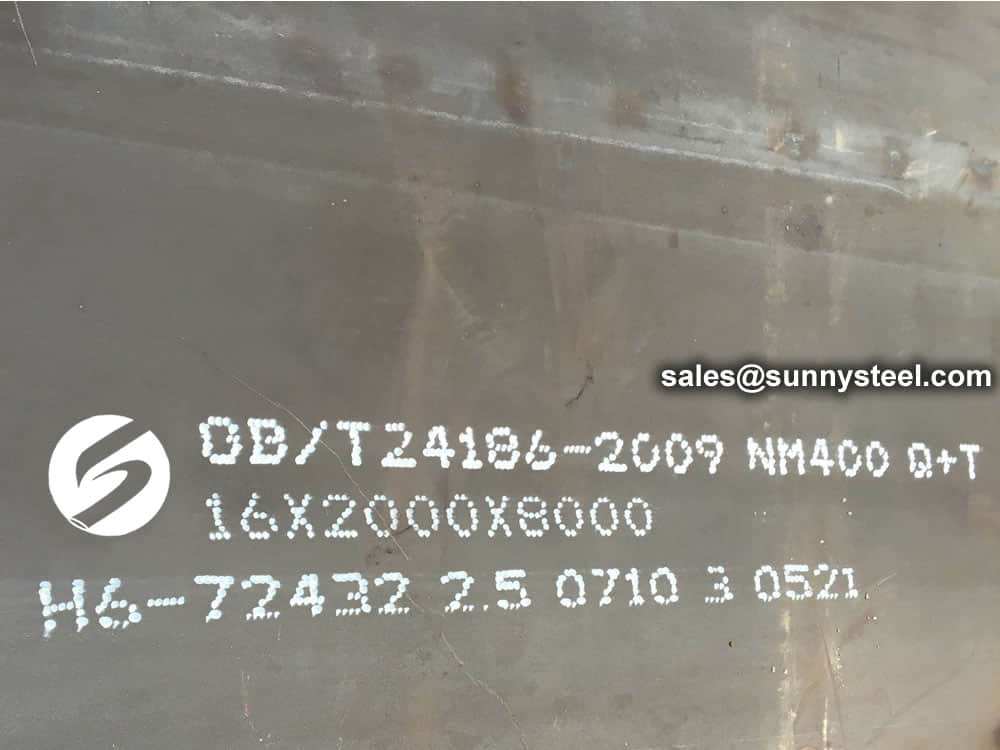

NM400 Steel Plate is a type of wear-resistant steel plate that is commonly used in various industrial applications.

Ceramic tile lined pipes are pipelines that have a ceramic tiles lining layer inside a steel pipe.

The wear resistance of the pulverized coal conveying pipeline of the boiler of the thermal power plant must be designed for leakproof, anti-corrosion, rain-proof, anti-freeze and other factors.