Get: 9 results / Total 2 pages

Industrial valves are critical devices used to control the direction, pressure, and flow of fluids (liquids, gases, powders ) in piping systems, ensuring safe and efficient operation.

A check valve is a mechanical device that allows the flow of fluid in one direction while preventing its backflow in the opposite direction.

The lift check valve ensures reliable backflow prevention in high-pressure pipelines, offering corrosion resistance and compact design for water, oil, and gas systems up to pn40 and 425°c.

The swing check valve is a high-performance non-return valve designed for robust backflow prevention in industrial pipelines, ensuring unidirectional flow for water, oil, gas, and chemical systems.

Upon encountering a specified flow rate, the disc rotates to a horizontal position, enabling forward flow. it returns to the valve seat when the flow stops to prevent backflow.

The cng lng cryogenic check valve ensures reliable backflow prevention in extreme low-temperature environments like lng and cng systems, featuring austenitic stainless steel for superior corrosion resistance up to -196°c and pn40 pressure ratings.

Bimetal clad pipe is cast with mold vanishing vacuum suction casting cladding process.

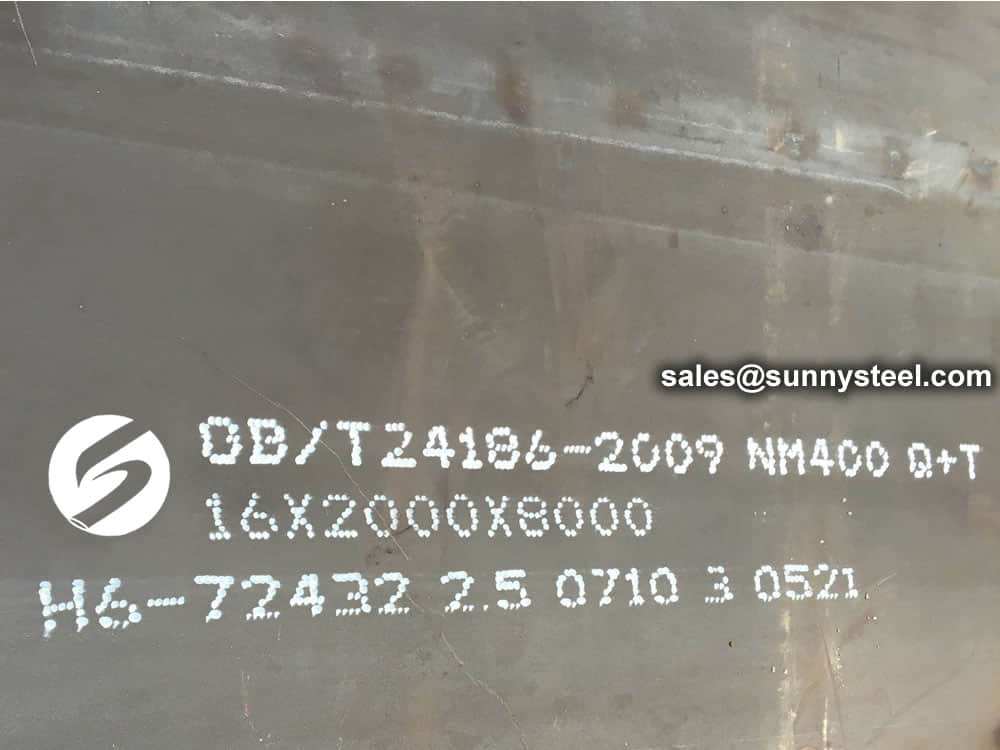

NM400 Steel Plate is a type of wear-resistant steel plate that is commonly used in various industrial applications.

Ceramic tile lined pipes are pipelines that have a ceramic tiles lining layer inside a steel pipe.

The wear resistance of the pulverized coal conveying pipeline of the boiler of the thermal power plant must be designed for leakproof, anti-corrosion, rain-proof, anti-freeze and other factors.