Get: 7 results / Total 2 pages

Industrial valves are critical devices used to control the direction, pressure, and flow of fluids (liquids, gases, powders ) in piping systems, ensuring safe and efficient operation.

Globe valves provide excellent throttling capability and precise flow control, making them ideal for applications requiring flow regulation, pressure control, and tight sealing in high-pressure and high-temperature systems.

A ball valve is a shut-off valve that allows, obstructs, and controls the flow of liquids, gases, and vapors in a piping system by rotating the ball having a bore inside the valve.

The control valve provides precise flow regulation with corrosion-resistant materials for water, oil, gas, and chemical systems, ensuring reliable performance up to pn40 and 450°c.

Api 602 forged globe valves are designed for high pressure and temperature applications in the oil, gas, and petrochemical industries.

The electric hydraulic balanced control valve ensures precise flow regulation with balanced plug design for reduced actuator load, ideal for high-pressure oil, gas, and chemical systems up to pn40 and 450°c.

Bimetal clad pipe is cast with mold vanishing vacuum suction casting cladding process.

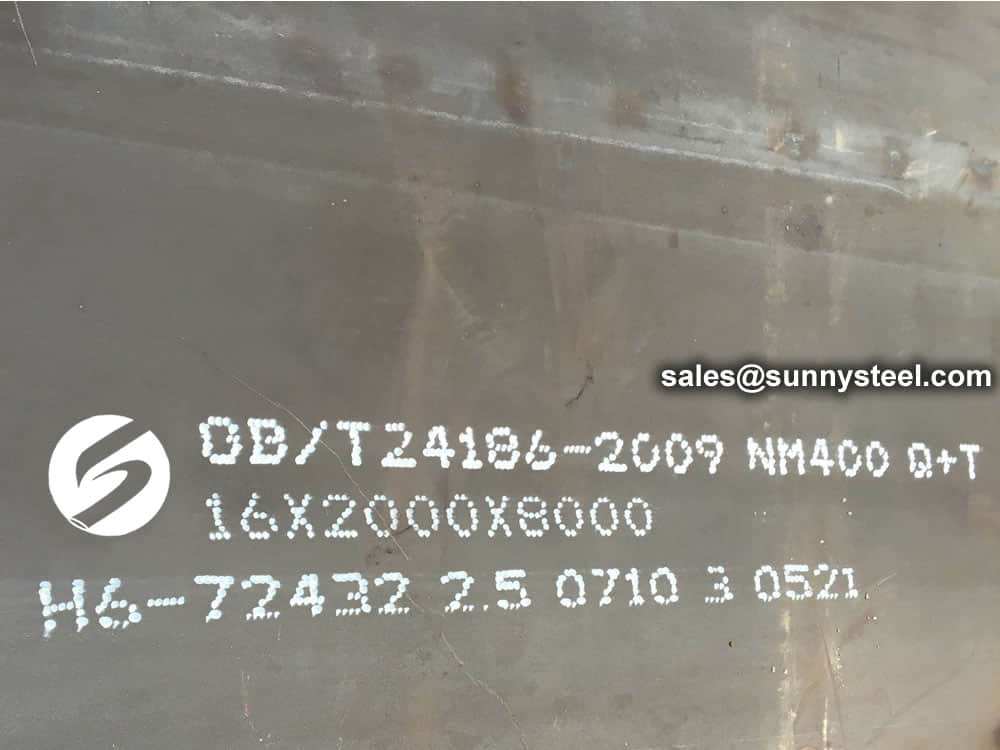

NM400 Steel Plate is a type of wear-resistant steel plate that is commonly used in various industrial applications.

Ceramic tile lined pipes are pipelines that have a ceramic tiles lining layer inside a steel pipe.

The wear resistance of the pulverized coal conveying pipeline of the boiler of the thermal power plant must be designed for leakproof, anti-corrosion, rain-proof, anti-freeze and other factors.