Get: 4 results

End cap, also known as pipe cap, are pipe fittings designed to serve as closures at the ends of a piping system, providing protection and sealing functionality.

Ansi/asme b16.9 pipe end caps are buttwelding fittings used to seal or close the end of a pipe. they are manufactured to specific dimensions, tolerances, and materials as defined by the ansi/asme b16.9 standard, ensuring they function reliably in various industrial piping systems for containment, safety, and system expansion.

A din 28011 pipe cap is a standard for a one-piece, torispherical pipe end closure designed for butt welding, suitable for use with pipes of external diameter (da) up to 4000 mm and nominal wall thickness (s) up to 50 mm. these caps are used to seal the end of a pipe in applications like pressure vessels and piping systems, often made from stainless steel.

Stainless steel pipe caps are butt-welded fittings designed to seal pipe ends, offering unmatched corrosion resistance and protection against environmental exposure, debris, and pressure loss. these caps are essential for boiler pipeline protection and erosion/corrosion resistance in industries such as petrochemical, chemical processing, food and beverage, and power generation.

Bimetal clad pipe is cast with mold vanishing vacuum suction casting cladding process.

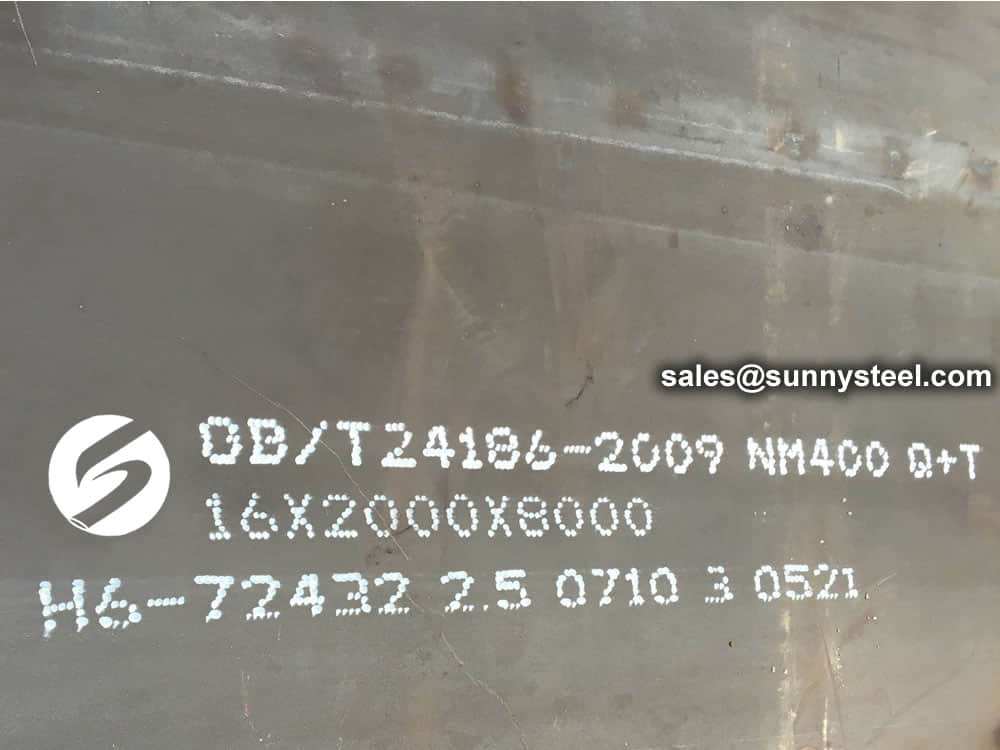

NM400 Steel Plate is a type of wear-resistant steel plate that is commonly used in various industrial applications.

Ceramic tile lined pipes are pipelines that have a ceramic tiles lining layer inside a steel pipe.

The wear resistance of the pulverized coal conveying pipeline of the boiler of the thermal power plant must be designed for leakproof, anti-corrosion, rain-proof, anti-freeze and other factors.