Tag# Pipe Bend search

Get: 28 results / Total 5 pages

Pipe Bends

Categories - Precision Flow Direction SolutionsPipe bends are curved piping components used to change the direction of fluid flow in pipelines, offering smooth transitions and reduced pressure drop for various industrial applications.

7D Pipe Bending

Product - Seamless And Welded 7d Pipe Bends For Superior Flow In High-pressure SystemsA 7d pipe bending is a pipe bend that the bend radius is 7 times the pipe outside diameter.

15CrMoG Bending

Product - Seamless 15crmog Alloy Steel Pipe Bends For High-pressure Industrial Applications15crmog pipe bending involves shaping seamless alloy steel pipes into bends (e.g., 3d, 5d, 7d, or 180° u-bends) for high-pressure, high-temperature applications. 15crmog, a chromium-molybdenum heat-resistant steel, contains approximately 0.15% carbon, chromium, and molybdenum, offering exceptional high-temperature strength (up to 550°c), oxidation resistance, and corrosion resistance.

12Cr1MoVG Pipe Bending

Product - Seamless 12cr1movg Alloy Steel Pipe Bends For High-pressure Industrial Applications12cr1movg pipe bending refers to the process of shaping 12cr1movg steel pipe into a curved form, often necessary for high-temperature and high-pressure applications like boiler tubes. 12cr1movg is a heat-resistant low-alloy steel containing chromium, molybdenum, and vanadium, which provides excellent strength and corrosion resistance at elevated temperatures.

ASTM A210 Grade C Pipe Bending

Product - Seamless Astm A210 Grade C Carbon Steel Pipe Bends For Industrial Boiler ApplicationsAstm a210 grade c pipe bending involves forming seamless medium-carbon steel tubes into bends (e.g., 3d, 5d, 7d, or 180° u-bends) for high-pressure boiler applications.

Cast Basalt Lined Bend

Product - Premium Abrasion & Corrosion BendHeavy-duty steel bends with seamless cast basalt lining for maximum wear and corrosion resistance in industrial fluid systems. cast basalt lined bends provide exceptional abrasion and corrosion protection with smooth basalt lining—ideal for industrial pipeline direction changes under harsh conditions.

搜索

搜索统计

6

产品0

文章Hot products

Bimetal Clad Pipe

Bimetal clad pipe is cast with mold vanishing vacuum suction casting cladding process.

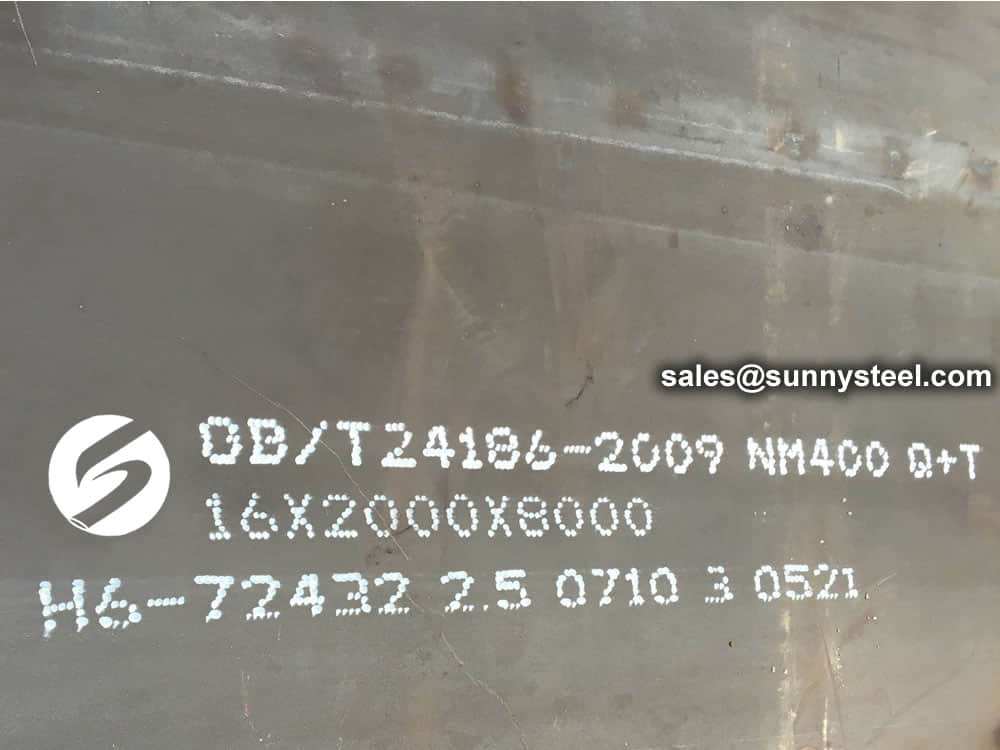

NM400 Steel Plate

NM400 Steel Plate is a type of wear-resistant steel plate that is commonly used in various industrial applications.

Ceramic Tile Lined Pipes

Ceramic tile lined pipes are pipelines that have a ceramic tiles lining layer inside a steel pipe.

Wear-Resistant Pipe Elbow For Boiler Powder Feed

The wear resistance of the pulverized coal conveying pipeline of the boiler of the thermal power plant must be designed for leakproof, anti-corrosion, rain-proof, anti-freeze and other factors.