Get: 6 results

A pipe reducer is a fitting used in piping systems to connect two pipes of different diameters. the fitting enables a smooth transition from a larger to a smaller pipe, which helps regulate fluid flow, manage pressure, and prevent issues like turbulence and leaks

A stainless steel reducer is a pipe fitting used to connect pipes of different diameters, enabling a smooth transition in flow within a piping system. they are made from stainless steel for durability and corrosion resistance and are essential in various industries like chemicals, oil and gas, and food and beverage.

Cast basalt pipe reducers enable smooth, abrasion-resistant transitions between pipe sizes—ideal for slurry, ash, and abrasive material systems.

Ceramic tile lined pipe reducers effectively control flow transitions in abrasive and corrosive environments, minimizing wear and ensuring long service life in slurry and bulk material systems.

Large-size eccentric reducers (≥24" or 610mm) designed for corrosion resistance, seamless flow transitions, and high-pressure performance in boiler, petrochemical, and industrial piping systems.

Eccentric reducers are fittings used to connect pipes of different diameters, characterized by offset centerlines between the larger and smaller ends, which allows for maintaining a consistent bottom of pipe elevation.

Bimetal clad pipe is cast with mold vanishing vacuum suction casting cladding process.

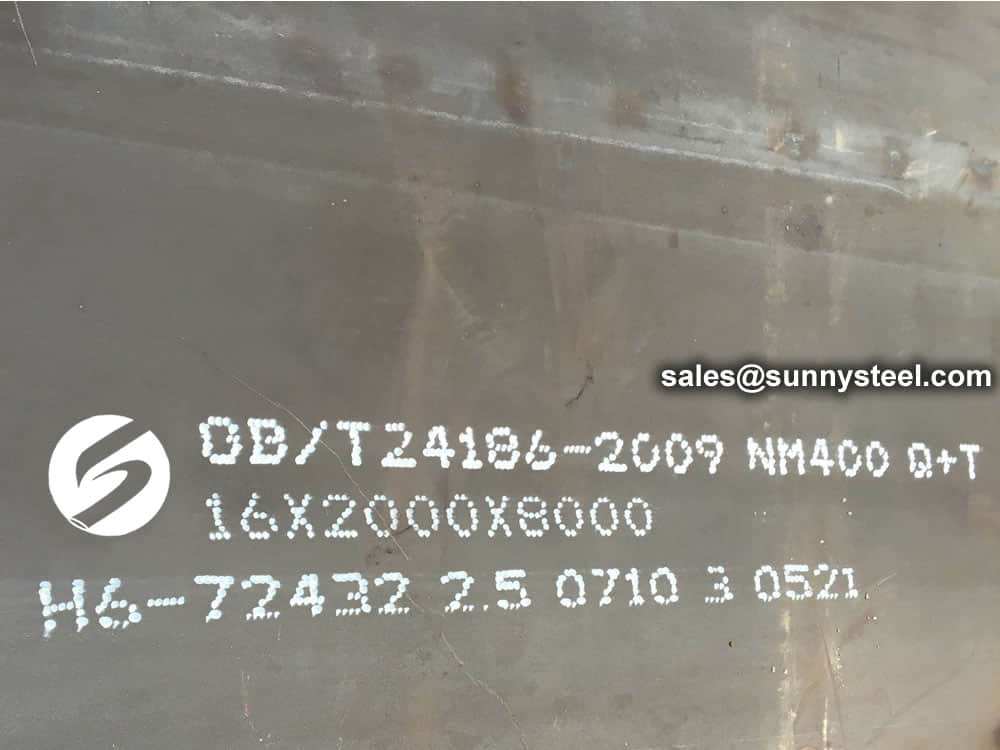

NM400 Steel Plate is a type of wear-resistant steel plate that is commonly used in various industrial applications.

Ceramic tile lined pipes are pipelines that have a ceramic tiles lining layer inside a steel pipe.

The wear resistance of the pulverized coal conveying pipeline of the boiler of the thermal power plant must be designed for leakproof, anti-corrosion, rain-proof, anti-freeze and other factors.