Seamless Ferritic Alloy Steel Pipe For High-temperature Service

Astm a335 p11 alloy steel pipe delivers strength and oxidation resistance for high-temperature service in boilers, heaters, and pressure piping systems.

Seamless Ferritic Alloy Steel Pipe For High-temperature Service

Astm a335 p11 alloy steel pipe delivers strength and oxidation resistance for high-temperature service in boilers, heaters, and pressure piping systems.

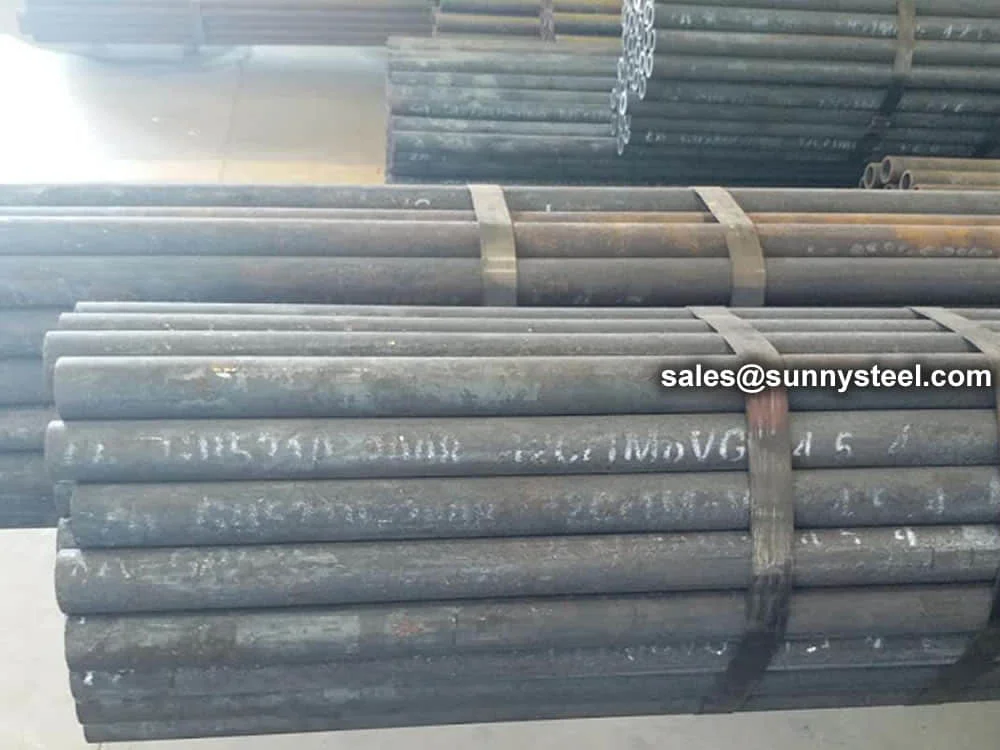

ASTM A335 P11 Seamless Pipe is a high-performance alloy steel pipe engineered for superior high-temperature strength and corrosion resistance in demanding applications. Conforming to the ASTM A335/ASME SA335 specification, this Chrome Moly Pipe is designed with a composition of 1.00-1.50% chromium and 0.44-0.65% molybdenum, making it ideal for boiler pipeline protection in power plants, refineries, petrochemical plants, and other industrial piping systems. Its seamless construction ensures exceptional durability and reliability under high-pressure and high-temperature conditions up to 550°C.

The ASTM A335 P11 Seamless Pipe is manufactured through hot-rolling or cold-drawing processes, followed by heat treatments such as normalizing at 900-960°C and tempering at 650-760°C to optimize mechanical properties. The chromium content enhances oxidation resistance and high-temperature strength, while molybdenum improves creep resistance, hardenability, and wear resistance, making it suitable for boiler pipeline protection. Available in sizes from 1/8” to 36” (NPS 1/8 to NPS 36, DN6 to DN900), with wall thicknesses ranging from SCH 20 to XXS, and lengths up to 13.5 meters or customized, it meets diverse project requirements.

The Seamless Alloy Pipes undergo rigorous testing, including tensile, flattening, hardness, and hydrostatic tests, to ensure compliance with ASTM A335 standards. With a minimum tensile strength of 415 MPa and yield strength of 205 MPa, the P11 pipe offers robust resistance to thermal stress and pressure, making it ideal for handling corrosive fluids and gases in petrochemical and power generation applications. Surface treatments such as galvanizing, FBE, or 3LPE coatings further enhance corrosion resistance, while plain or beveled ends facilitate seamless integration into industrial piping systems.

Compared to other grades like P5 or P22, the ASTM A335 P11 Seamless Pipe provides a cost-effective balance of high-temperature performance and durability, making it a preferred choice for power plants and refinery applications. Its compatibility with fittings and flanges under ASTM A234 WP11 standards ensures seamless integration into complex piping networks. The pipe’s ability to resist hydrogen sulfide corrosion and stress corrosion cracking makes it ideal for oil and gas pipelines and high-pressure industrial piping systems requiring reliable boiler pipeline protection.

Engineered to address critical challenges like pipeline wear, corrosion, and thermal stress, the ASTM A335 P11 Seamless Pipe delivers unmatched performance in high-throughput industrial systems. Its advanced alloy composition and seamless construction make it a reliable choice for engineers seeking durable industrial piping solutions for extreme environments, ensuring safety, longevity, and efficiency in Chrome Moly Pipe applications.

Withstands temperatures up to 550°C for boilers and refineries.

Chromium and molybdenum ensure resistance to oxidation and corrosion.

Molybdenum enhances durability in high-pressure systems.

Uniform construction ensures reliability in high-pressure applications.

Long lifespan reduces maintenance and replacement costs.

Ideal for boilers, refineries, and petrochemical systems.

| Feature | ASTM A335 P11 | ASTM A335 P22 | ASTM A335 P91 |

|---|---|---|---|

| Material Type | Alloy Steel | Alloy Steel | Alloy Steel |

| Chromium Content | 1.00-1.50% | 1.90-2.60% | 8.00-9.50% |

| Molybdenum Content | 0.44-0.65% | 0.87-1.13% | 0.85-1.05% |

| Temperature Range | High (up to 550°C) | High (up to 600°C) | High (up to 650°C) |

| Corrosion Resistance | Good (With coatings) | Good (With coatings) | Excellent (With coatings) |

| Applications | Boilers, Refineries | Boilers, Refineries | Power Plants, Supercritical Boilers |

| Tensile Strength (MPa) | 415 (min) | 415 (min) | 585 (min) |

| Yield Strength (MPa) | 205 (min) | 205 (min) | 415 (min) |

| Key Advantage | Cost-effective high-temp | Balanced high-temp strength | Superior creep strength |

| Element | Composition (%) |

|---|---|

| Carbon (C) | 0.05-0.15 |

| Manganese (Mn) | 0.30-0.60 |

| Phosphorus (P) | ≤0.025 |

| Sulfur (S) | ≤0.025 |

| Silicon (Si) | 0.50-1.00 |

| Chromium (Cr) | 1.00-1.50 |

| Molybdenum (Mo) | 0.44-0.65 |

| Property | Value |

|---|---|

| Tensile Strength, min (MPa) | 415 |

| Yield Strength, min (MPa) | 205 |

| Elongation, min (%) | 30 |

| Hardness, max (HBW) | 163 |

| Spec | Grade | O.D. (mm) | W.T. (mm) | Length (mm) | QTY (pcs) |

QTY (Tons) |

|---|---|---|---|---|---|---|

| ASTM A335 | P11 | 60.30 | 8.74 | - | 12 | - |

| ASTM A335 | P11 | 73.00 | 7.00 | - | 1 | - |

| ASTM A335 | P11 | 73.00 | 9.00 | - | 1 | - |

| ASTM A335 | P11 | 88.90 | 5.49 | 12000 | 7 | 0.938 |

| ASTM A335 | P11 | 88.90 | 5.49 | 6000–12000 | 14 | 1.472 |

| ASTM A335 | P11 | 88.90 | 7.62 | 12000 | 8 | 1.450 |

| ASME SA335 | P11 | 88.90 | 7.62 | 6000–12000 | 2 | 0.312 |

| ASTM A335 | P11 | 88.90 | 7.62 | - | 2 | - |

| MAL 037 | P11 | 88.90 | 7.62 | 6000–12000 | 4 | 0.650 |

| ASTM A335 | P11 | 88.90 | 11.13 | - | 14 | - |

| ASTM A335 | P11 | 114.30 | 6.02 | - | 1 | - |

| ASTM A335 | P11 | 114.30 | 8.56 | 6000–12000 | 5 | 0.930 |

| MAL 037 | T11 | 114.30 | 8.56 | - | 16 | 2.612 |

| ASME SA332 | P11 | 114.30 | 10.00 | - | 1 | - |

| ASME SA333 | P11 | 141.30 | 6.55 | 14990 | 3 | 0.992 |

| ASME SA334 | P11 | 141.30 | 6.55 | - | 26 | - |

| ASME SA335 | P11 | 141.30 | 6.55 | - | 2 | 0.356 |

| ASTM A335 | P11 | 168.30 | 7.11 | 8000–12000 | 50 | 15.152 |

| ASTM A335 | P11 | 168.30 | 10.97 | 6000–12000 | 3 | 1.204 |

| ASTM A335 | P11 | 168.30 | 10.97 | - | 2 | - |

| ASTM A335 | P11 | 219.10 | 12.70 | - | 9 | - |

| ASTM A335 | P11 | 273.00 | 16.00 | - | 3 | - |

| ASTM A335 | P11 | 273.00 | 18.50 | - | 5 | - |

| ASTM A335 | P11 | 325.00 | 14.00 | - | 1 | - |

| ASTM A335 | P11 | 325.00 | 16.00 | - | 10 | - |

| ASTM A335 | P11 | 325.00 | 20.00 | - | 3 | - |

| ASTM A335 | P11 | 325.00 | 22.00 | - | 18 | - |

| ASTM A335 | P11 | 325.00 | 26.00 | - | 4 | - |

| ASTM A335 | P11 | 325.00 | 30.00 | - | 2 | - |

| ASTM A335 | P11 | 609.60 | 30.75 | - | 4 | - |

Length: 5800mm; 6000mm; 6096mm; 7315mm; 11800mm; 12000mm; etc.

Max length: 16000mm (U-bending also available upon request).

Note: This is a partial stock list. For other grades or sizes, please contact us for more information or availability.

Alloy steel pipes are categorized by both standards and grades, each designed for specific performance requirements and applications. Common standards include ASTM A335, A519, and A213, while grades like P5, P9, P11, P22, and P91 are frequently used within these standards.

| Standard | Detailed Grades | Main Applications |

|---|---|---|

| ASTM A335 / ASME SA335 | P1, P2, P5, P9, P11, P12, P15, P21, P22, P23, P24, P36, P91, P92, P122, P911 | High-temperature pressure systems: power plants, refineries, and chemical plants |

| ASTM A213 / ASME SA213 | T2, T5, T5b, T9, T11, T12, T17, T22, T23, T24, T91, T92, T122, T911 | Boiler tubes, superheaters, and heat exchangers |

| ASTM A519 | 4130, 4135, 4140, 4145, 4150, 1020, 1026, 1330, 8620 | Mechanical tubing, structural applications, automotive components |

| API 5L | A25, A, B, X42, X46, X52, X56, X60, X65, X70, X80, X100 | Oil and gas transmission pipelines (onshore and offshore) |

| EN 10216‑2 | 13CrMo4-5, 10CrMo9-10, 12CrMo19-5, X10CrMoVNb9-1, X11CrMo5, 14MoV6-3, X20CrMoV12-1 | European pressure vessels and high-temperature piping |

| GB / SH Standards | 15CrMoG, 12Cr1MoVG, 10CrMo910, 12CrMo, 1Cr5Mo, WB36, 10Cr9Mo1VNb (equiv. T91) | Petrochemical, power generation, high-pressure boilers in Chinese systems |

Alloy steel is made by combining carbon steel with one or several alloying elements, such as titanium, copper, chromium, aluminum, manganese, silicon, and nickel. This produces specific properties that are not found in standard carbon steel. Common alloy steel grades include 4130, 4140, 4340, and 8620 for their balance of characteristics like strength, toughness, machinability, and weldability.

Alloy steel pipes offer superior strength, temperature and corrosion resistance, making them ideal for demanding environments across energy, petrochemical, construction, and more.

Used extensively in drilling, subsea and onshore pipelines for crude oil, natural gas, and refined products due to high strength and corrosion resistance.

Ideal for transporting corrosive chemicals, high-pressure reactor feeds, and heat exchanger tubing where carbon steel fails.

Used in high-temp boiler tubes, superheaters, reheaters, and steam piping; withstands extreme temperatures and pressures efficiently.

Used as structural pipelines, piling tubes, and transport lines in high-rise buildings and bridges due to high structural strength.

Suitable for transporting liquefied gases and cold media, where toughness and strength must endure sub-zero temperatures.

Alloy steel pipes are fully recyclable and support energy-efficient systems, aligning with green standards in modern industry.

15crmog seamless pipe offers high-temperature stre...

Wb36 seamless pipe offers high strength and creep ...

Astm a335 p9 seamless pipe offers high-temperature...

Astm a333 grade 6 seamless pipe offers low-tempera...

12cr1movg seamless pipe offers high-temperature st...

16mn seamless pipe offers high strength and weldab...