Pressure And Structural Use

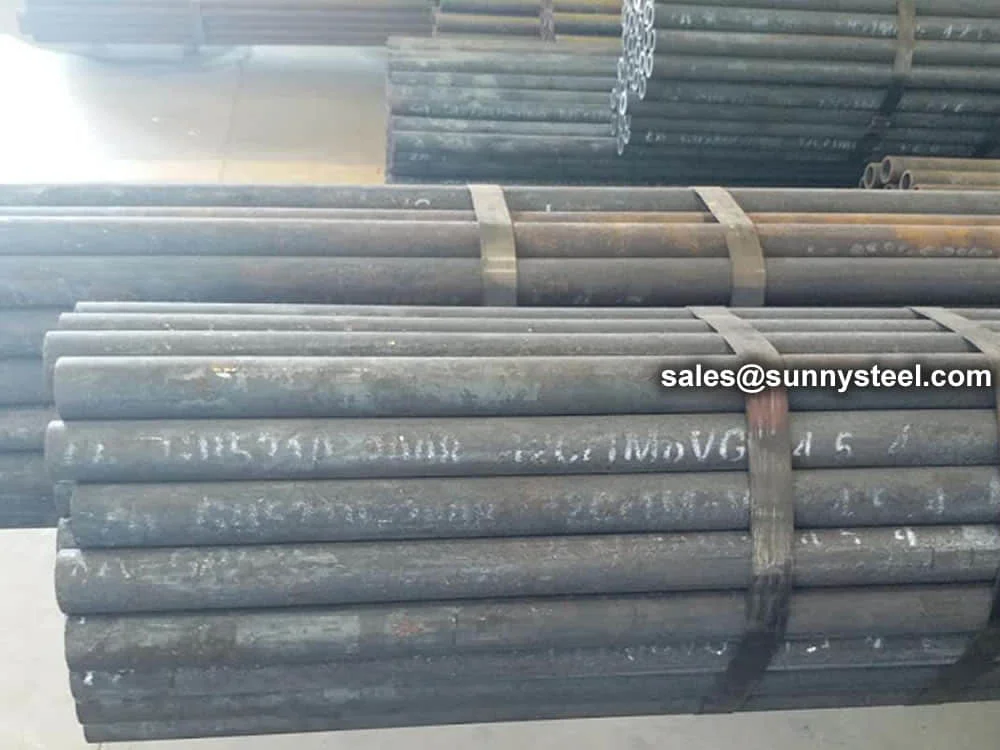

16mn seamless pipe offers high strength and weldability for pressure vessels, boilers, and industrial piping applications.

Pressure And Structural Use

16mn seamless pipe offers high strength and weldability for pressure vessels, boilers, and industrial piping applications.

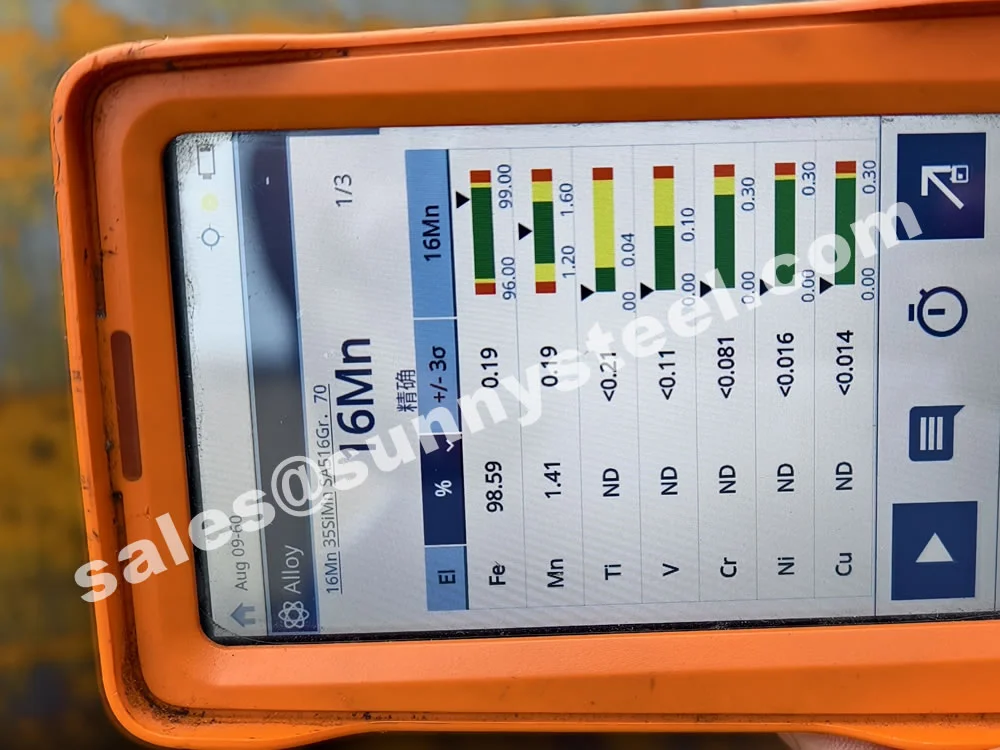

16Mn Seamless Pipe, also known as Q345 in modern Chinese standards (GB/T 1591-2008), is a high-strength low-alloy structural steel pipe designed for excellent mechanical properties, weldability, and corrosion resistance. With a carbon content of 0.12-0.20% and alloying elements like manganese (0.7-1.0%), silicon, and traces of vanadium, niobium, and titanium, it is ideal for boiler pipeline protection in medium and low-pressure boilers, pressure vessels, oil tanks, and industrial piping systems. Its seamless construction ensures durability and reliability in demanding applications like shipbuilding, bridges, and mechanical structures.

The 16Mn Seamless Pipe is manufactured through hot-rolling or cold-drawing processes, typically delivered in a hot-rolled or normalized state to optimize mechanical properties. The manganese content enhances strength and toughness, while micro-alloying elements like Ti, Nb, and V refine grain structure, improving low-temperature performance and weldability. Available in sizes from 10mm to 1200mm OD, with wall thicknesses from 2mm to 80mm, and lengths up to 12 meters or customized, it meets diverse project requirements. Its yield strength of 345 MPa (hence the Q345 designation) makes it suitable for structural and pressure vessel applications.

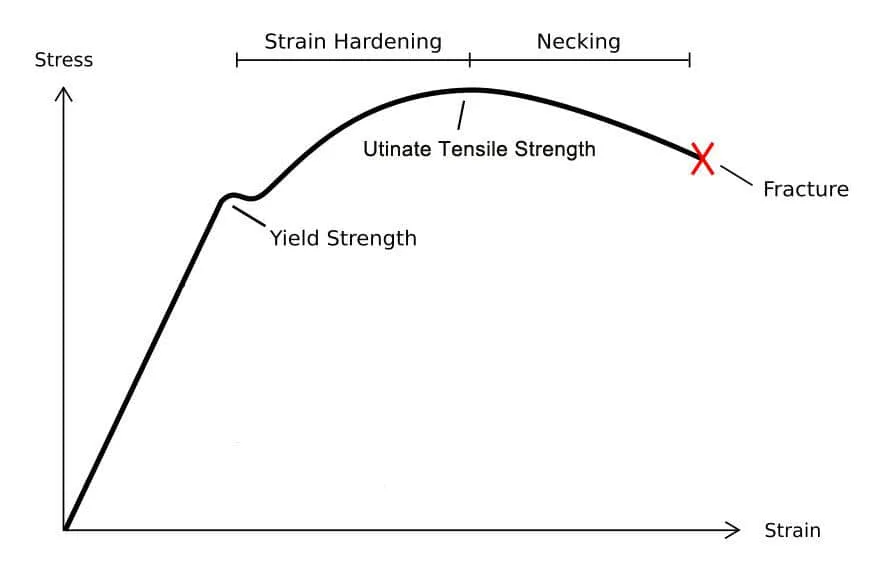

The Seamless Alloy Pipes undergo rigorous testing, including tensile, flattening, flaring, and hydrostatic tests, to ensure compliance with standards like GB/T 8162, GB/T 8163, and GB 6479. With a tensile strength of 470-630 MPa and yield strength of 345 MPa (for thicknesses ≤16mm), the 16Mn pipe offers robust resistance to mechanical stress and moderate corrosion. Surface treatments such as black varnish, galvanizing, or 3LPE coatings enhance corrosion resistance, while plain or beveled ends facilitate integration into industrial piping systems. Due to its slight hardening tendency, preheating (150-200°C) is recommended for welding on thick or rigid structures to prevent cold cracking.

Compared to grades like 15CrMoG or ASTM A335 P11, the 16Mn Seamless Pipe has lower alloy content, making it more cost-effective for applications not requiring extreme high-temperature resistance (typically up to 350°C for pressure vessels). Unlike 12Cr1MoVG, which includes vanadium for enhanced creep resistance, 16Mn prioritizes weldability and toughness, making it versatile for structural uses. Its modern equivalent, Q345, includes grades A, B, C, D, and E, with improved low-temperature impact toughness (tested at +20°C to -40°C), making it a preferred choice for diverse applications like cranes, mining equipment, and pressure vessels.

| Wall Thickness (S) | Tolerance | |

|---|---|---|

| < 3.5 mm | +15% (min +0.48 mm) | |

| −10% (min −0.32 mm) | ||

| 3.5 – 20 mm | +15%, −10% | |

| > 20 mm | OD < 219 mm | ±10% |

| OD ≥ 219 mm | +12.5%, −10% | |

| Feature | 16Mn (Q345) | 15CrMoG | ASTM A335 P11 |

|---|---|---|---|

| Material Type | Low Alloy Steel | Alloy Steel | Alloy Steel |

| Carbon Content | 0.12-0.20% | 0.12-0.18% | 0.05-0.15% |

| Manganese Content | 0.70-1.00% | 0.40-0.70% | 0.30-0.60% |

| Chromium Content | ≤0.30% | 0.80-1.10% | 1.00-1.50% |

| Temperature Range | Up to 350°C | Up to 550°C | Up to 550°C |

| Corrosion Resistance | Moderate (With coatings) | Excellent (With coatings) | Good (With coatings) |

| Applications | Pressure Vessels, Boilers, Structures | Boilers, Petrochemical | Boilers, Refineries |

| Tensile Strength (MPa) | 470-630 | 440-640 | 415 (min) |

| Yield Strength (MPa) | 345 (min) | 235 (min) | 205 (min) |

| Key Advantage | High strength, weldability | Balanced high-temp strength | Cost-effective high-temp |

| Element | Composition (%) |

|---|---|

| Carbon (C) | 0.12-0.20 |

| Silicon (Si) | 0.20-0.55 |

| Manganese (Mn) | 0.70-1.00 |

| Phosphorus (P) | ≤0.045 |

| Sulfur (S) | ≤0.045 |

| Chromium (Cr) | ≤0.30 |

| Nickel (Ni) | ≤0.30 |

| Vanadium (V) | ≤0.08 |

| Property | Value |

|---|---|

| Tensile Strength (MPa) | 470-630 |

| Yield Strength, min (MPa) | 345 (≤16mm) |

| Elongation, min (%) | 21 |

| Impact Toughness (J) | ≥34 (at 0°C, Q345B) |

| EU EN |

USA | Germany DIN / WNr |

Japan JIS |

France AFNOR |

UK BS |

Old EN | Italy UNI |

Belgium NBN |

Spain UNE |

China GB |

Finland SFS |

Austria ÖNORM |

Norway NS |

ISO | Portugal NP |

India IS |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| S355J0 (1.0553) |

A441 A633 |

St52-3U | SS490B | E36-3 | 50C | Fe510C | Fe510C | AE355C | AE355C | 16Mn | Fe52C | St510C | NS12153 | E355C Fe510C |

FE510-C | Fe570HT |

16Mn is a versatile low‑alloy structural steel with high strength, toughness, weldability, and cost-efficiency, making it a top choice across diverse industrial sectors.

Used in stairs, handrails, pillars and general steelwork in buildings, offering reliable load-bearing capacity and weldability.

Ideal for bridge bearings, beams and tie rods with high tensile strength and weight saving benefits.

Used in chassis, suspension and drivetrain parts, balancing lightweight design with high strength and impact resistance.

Ideal for gear shafts and frames due to strong fatigue and wear resistance.

Widely used in pipelines and structural components for oil, gas and chemical plants with good corrosion and weld properties.

Used in mining supports, underground piping and water infrastructure, offering high strength and long service span.

15crmog seamless pipe offers high-temperature stre...

Wb36 seamless pipe offers high strength and creep ...

Astm a335 p9 seamless pipe offers high-temperature...

Astm a333 grade 6 seamless pipe offers low-tempera...

Astm a335 p11 alloy steel pipe delivers strength a...

12cr1movg seamless pipe offers high-temperature st...