Seamless Chrome Moly Piping For Superior Creep And Corrosion Resistance

Astm a335 p92 high pressure boiler pipe delivers exceptional creep strength and corrosion resistance, ideal for ultra-supercritical boilers and petrochemical applications.

Seamless Chrome Moly Piping For Superior Creep And Corrosion Resistance

Astm a335 p92 high pressure boiler pipe delivers exceptional creep strength and corrosion resistance, ideal for ultra-supercritical boilers and petrochemical applications.

ASTM A335 P92 Alloy Steel Pipe is a high-performance seamless ferritic alloy steel pipe designed for high-pressure and high-temperature boiler systems. Manufactured in accordance with ASTM A335/ASME SA335 standards, this Chrome Moly Pipe contains enhanced chromium (8.50–9.50%) and molybdenum (0.30–0.60%) with additions of niobium, vanadium, and nitrogen, delivering exceptional creep strength and oxidation resistance.

P92 is widely used in supercritical and ultra-supercritical boiler systems in power plants where temperatures exceed 600°C. Its high tensile and yield strength ensure long-term stability under intense thermal and mechanical stress. Compared to P91, P92 offers improved performance at higher temperatures, better microstructural stability, and longer service life under prolonged operation.

The pipe undergoes normalizing, tempering, and air cooling to achieve the required mechanical properties. It is compatible with ASTM A234 WP92 alloy steel fittings, ensuring full system compatibility. Common applications include superheater tubes, reheater coils, header pipes, and main steam lines in fossil fuel and combined-cycle plants.

The seamless construction of ASTM A335 P92 Pipe eliminates weld defects and ensures uniform grain structure for optimum performance. Pre-weld and post-weld heat treatment are mandatory to avoid hardening and reduce risk of cracking during service.

Engineers favor this grade for its ability to operate in environments with extreme pressure, temperature, and corrosion. The pipe's advanced composition supports long-term durability, low thermal fatigue, and reduced maintenance in critical power generation applications.

Operates reliably above 600°C in ultra-supercritical boiler systems.

Improved alloy composition enhances creep resistance for long-term use.

High chromium content protects against oxidation in steam environments.

Ensures leak-free performance under fluctuating pressure and temperature.

Resists microstructural degradation for long-term stability and reduced maintenance.

| Element | Composition (%) |

|---|---|

| Carbon (C) | 0.07–0.13 |

| Manganese (Mn) | 0.30–0.60 |

| Phosphorus (P) | ≤0.02 |

| Sulfur (S) | ≤0.01 |

| Silicon (Si) | 0.20–0.50 |

| Chromium (Cr) | 8.50–9.50 |

| Molybdenum (Mo) | 0.30–0.60 |

| Vanadium (V) | 0.15–0.25 |

| Niobium (Nb) | 0.04–0.09 |

| Nitrogen (N) | 0.03–0.07 |

| Property | Value |

|---|---|

| Tensile Strength, min (MPa) | 620 |

| Yield Strength, min (MPa) | 440 |

| Elongation, min (%) | 20 |

| Hardness, max (HBW) | 250 |

ASTM A335 P92 pipes are fully compatible with ASTM A234 WP92 pipe fittings, ensuring uniform mechanical and chemical performance across high-temperature piping systems. These fittings are essential in assembling complex layouts in boilers and superheaters, where thermal and pressure integrity is critical.

Direct steam and hot gas flow around bends without weakening structural integrity.

Allow distribution and redirection of high-pressure steam in power systems.

Ensure smooth transitions and end-sealing in alloy piping systems.

| Grade | Chromium (Cr) | Molybdenum (Mo) | Other Elements | Max Working Temp (°C) | Key Feature |

|---|---|---|---|---|---|

| P92 | 8.50–9.50% | 0.30–0.60% | V, Nb, N | 620–650°C | Improved creep strength and oxidation resistance |

| P91 | 8.00–9.50% | 0.85–1.05% | V, Nb | 590–610°C | High strength, lower cost than P92 |

| P22 | 1.90–2.60% | 0.87–1.13% | – | 540–570°C | Good weldability, moderate temperature resistance |

ASTM A335 chrome moly pipes are widely used in various industries due to their excellent mechanical properties and resistance to high temperatures.

Used in high-temperature and high-pressure boiler tubes, superheaters, and reheaters for efficient energy conversion.

Applied in refineries and petrochemical plants to transport high-temperature hydrocarbons.

Used in facilities handling corrosive and high-temperature fluids during various chemical reactions.

Employed in nuclear power plants for critical piping systems resistant to extreme heat and pressure.

Used in furnaces and heat exchangers due to excellent resistance to high temperature and thermal fatigue.

Applied in high-pressure steam systems in industries like pulp and paper where thermal durability is essential.

Astm a335 p5 alloy steel pipe provides excellent h...

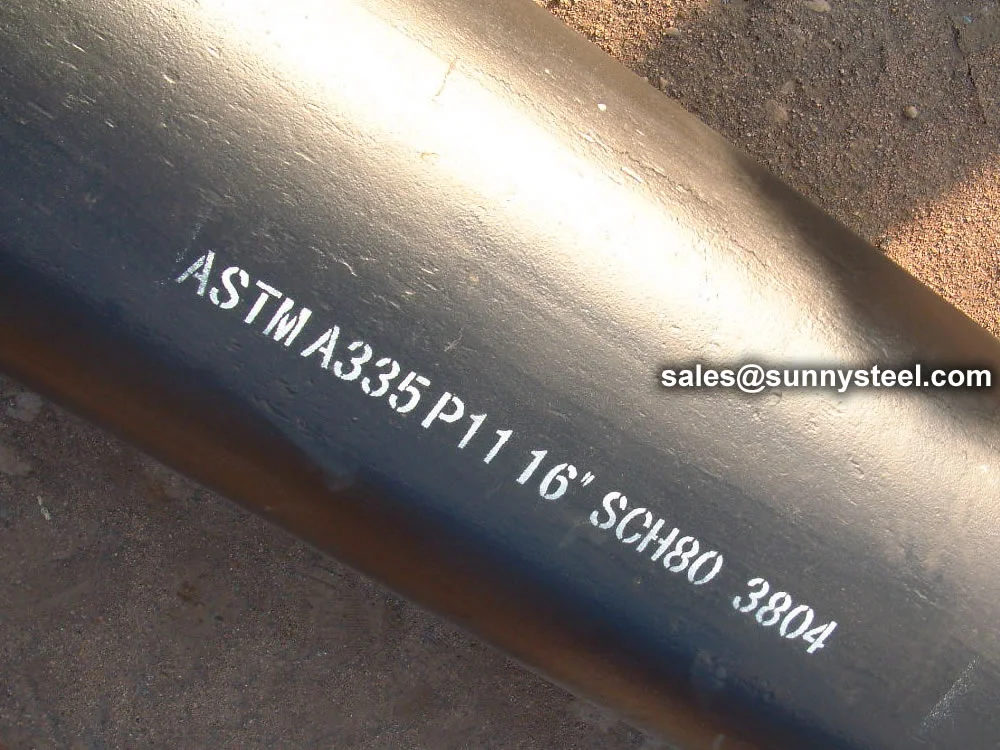

Astm a335 p11 alloy steel pipe provides reliable h...

Astm a335 p22 pipe offers excellent corrosion resi...