Get: 12 results

Abrasive materials ceramic lined bend pipe delivers superior wear resistance against harsh flow media like slurry and ash, extending service life and minimizing downtime in demanding industries.

Heavy-duty steel bends with seamless cast basalt lining for maximum wear and corrosion resistance in industrial fluid systems. cast basalt lined bends provide exceptional abrasion and corrosion protection with smooth basalt lining—ideal for industrial pipeline direction changes under harsh conditions.

Steel bend pipe with ceramic lining for superior abrasion, corrosion, and thermal protection in challenging industrial flow curves.

Wear resistant ceramic lined pipe bends provide unmatched protection in abrasive and corrosive flow environments, reducing downtime and maximizing equipment longevity at directional changes.

Wear-resistant lined bends and pipes offer superior durability and extended service life for pneumatic conveying systems handling abrasive powders or granules.

Abrasion-resistant alumina ceramic-lined bends provide excellent wear and corrosion protection for pipelines handling abrasive and corrosive media in harsh industrial environments.

Cast basalt bends offer superior abrasion and corrosion resistance for industrial pipelines. perfect for abrasive material transport, ensuring durability and low maintenance.

High alumina ceramic lined bend delivers excellent abrasion and corrosion resistance with a smooth ceramic interior, ideal for extending service life in high-wear pipeline systems.

Alumina ceramic sleeve lined pipe bends offer outstanding abrasion resistance and extended service life in elbows and curved pipelines carrying aggressive media like slurry, ash, or powder.

Alumina ceramic lined wear resistant bends deliver exceptional protection against abrasion and erosion, extending pipeline service life in abrasive flow applications like slurry, ash, and ore handling.

Ceramic‑lined flanged bends provide exceptional wear, corrosion, and heat resistance in abrasive slurry, ash, or chemical pipeline systems—ideal for flange-connected elbows.

Steel 180° u-bend fitted with ceramic lining for superior abrasion, corrosion, and thermal resistance in tight-radius piping.

Bimetal clad pipe is cast with mold vanishing vacuum suction casting cladding process.

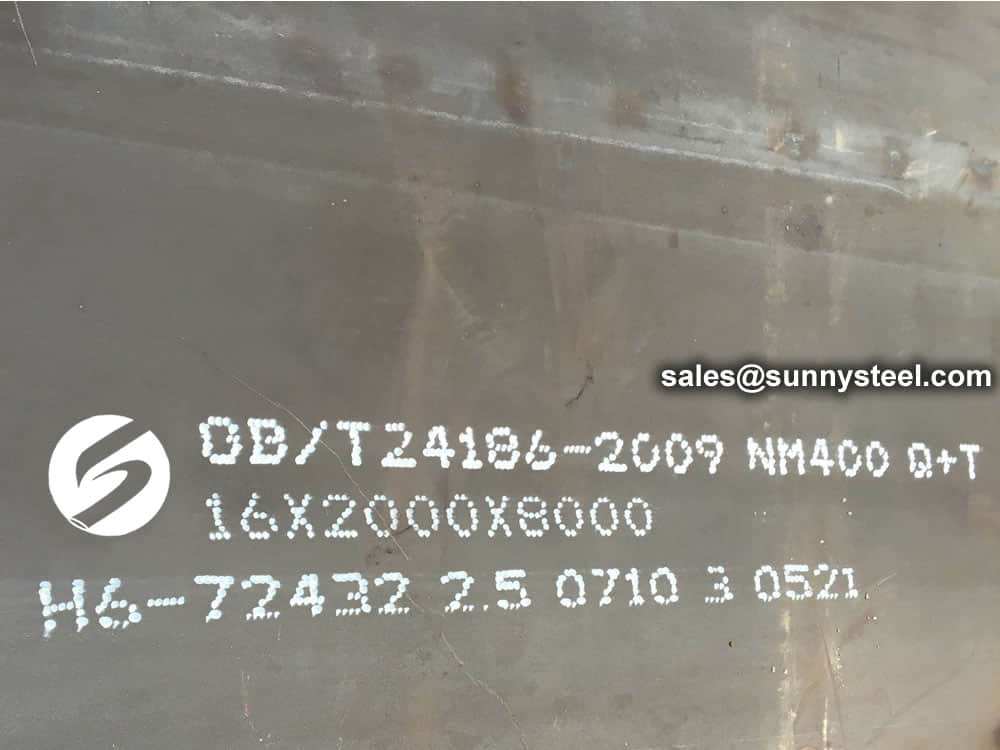

NM400 Steel Plate is a type of wear-resistant steel plate that is commonly used in various industrial applications.

Ceramic tile lined pipes are pipelines that have a ceramic tiles lining layer inside a steel pipe.

The wear resistance of the pulverized coal conveying pipeline of the boiler of the thermal power plant must be designed for leakproof, anti-corrosion, rain-proof, anti-freeze and other factors.