High-strength Carbon Steel Tubes For High-pressure Boiler Applications

Gb 5310 25mng seamless boiler tubes, compliant with gb/t 5310-2017, are high-strength carbon steel tubes designed for high-pressure boilers, offering excellent mechanical properties and corrosion resistance for superheaters, reheaters, and steam pipelines.

High-strength Carbon Steel Tubes For High-pressure Boiler Applications

Gb 5310 25mng seamless boiler tubes, compliant with gb/t 5310-2017, are high-strength carbon steel tubes designed for high-pressure boilers, offering excellent mechanical properties and corrosion resistance for superheaters, reheaters, and steam pipelines.

GB 5310 25MnG seamless boiler tubes, compliant with GB/T 5310-2017, are high-strength carbon structural steel tubes designed for high-pressure boilers operating at pressures ≥9.8 MPa and temperatures between 450°C and 650°C. These tubes are manufactured using seamless processes, either hot-rolled (extrusion, expansion) or cold-drawn (rolling), ensuring superior dimensional accuracy and structural integrity. They are ideal for superheaters, reheaters, economizers, and steam pipelines in power plant boilers, with wall temperatures up to 510°C for heating surfaces and 450°C for headers or steam pipes.

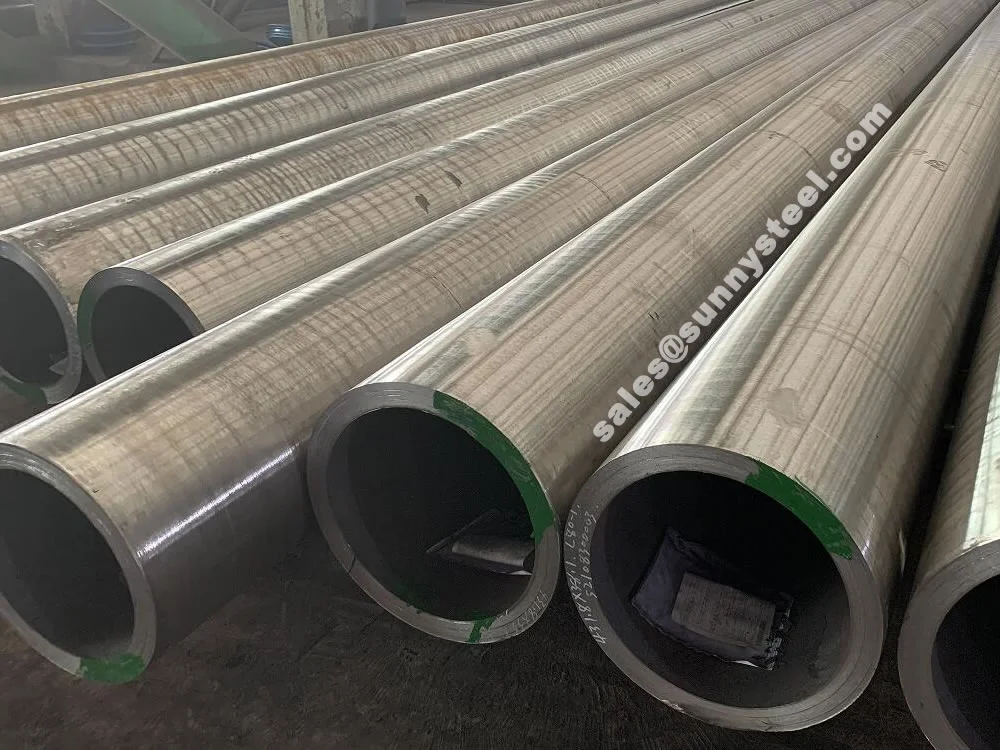

Available in outer diameters from 23 mm to 1500 mm and wall thicknesses from 2.8 mm to 150 mm, GB 5310 25MnG seamless tubes offer excellent tensile strength (485–640 MPa) and improved corrosion resistance compared to GB 3087 grades. The manufacturing process involves smelting via electric furnace, oxygen converter, or electroslag remelting, with tube blanks produced by continuous casting, die casting, or hot rolling (forging). Heat treatment (normalizing at 900–940°C) enhances mechanical properties, while rigorous testing (hydraulic, flattening, flaring, ultrasonic, and low-power tests) ensures compliance with GB/T 5310-2017 and GB/T 699 standards.

Compared to GB 5310 20G or alloy grades like 15CrMoG, 25MnG tubes provide higher strength and better toughness due to increased manganese content (0.7–1.0%), making them suitable for demanding high-pressure applications. Weldability is good, typically using manual welding (e.g., E4303 or E4315 electrodes) or gas-shielded welding without preheating. Surface treatments like varnishing or galvanizing prevent rust, and tubes are delivered with plain, beveled, or threaded ends. These tubes are widely used in power generation, petrochemicals, and industrial boiler systems, ensuring reliable performance under high-pressure and high-temperature conditions.(https://www.svsteelpipe.com/standard/gb-t5310.html)

GB 5310 25MnG seamless boiler tubes are a robust, cost-effective solution for high-pressure boiler systems, offering durability, safety, and efficiency in critical industrial environments.

| Element | Composition (%) |

|---|---|

| Carbon (C) | 0.22–0.27 |

| Silicon (Si) | 0.17–0.37 |

| Manganese (Mn) | 0.70–1.00 |

| Phosphorus (P) | ≤0.025 |

| Sulfur (S) | ≤0.015 |

| Property | Value |

|---|---|

| Tensile Strength (MPa) | 485–640 |

| Yield Strength (MPa) | ≥275 |

| Elongation, min (%) | ≥20 |

| Impact Energy (J, 0°C) | ≥27 |

GB 5310 25MnG Seamless Boiler Tubes are designed for high-pressure and high-temperature applications, providing exceptional boiler pipeline protection. Manufactured to GB 5310 standards, these seamless alloy tubes are made from low-alloy steel with manganese, delivering outstanding corrosion resistance and high-temperature performance up to 650°C. Perfect for power generation, petrochemical, and boiler systems, these tubes ensure reliable and safe operation in demanding industrial environments.

Produced through advanced seamless processes like hot-rolling or cold-drawing, GB 5310 25MnG tubes undergo precise heat treatment to optimize mechanical properties. The manganese content enhances resistance to oxidation and corrosion, making them ideal for handling corrosive fluids in high-pressure boiler systems. Their low thermal expansion coefficient minimizes thermal stress, ensuring structural stability during temperature fluctuations. Available in sizes from 1/2” to 24” (DN15 to DN600), with wall thicknesses from SCH 40 to SCH 160, and lengths up to 12 meters or customized, these tubes offer precise dimensional accuracy for seamless integration into industrial piping systems.

The 25MnG seamless boiler tubes undergo stringent testing, including tensile, hardness, flattening, and hydrostatic tests, to comply with GB 5310 standards, ensuring consistent quality and performance. With high tensile and yield strength, coupled with excellent toughness, these tubes reduce the risk of brittle fracture, making them a reliable choice for boiler pipeline protection. Surface treatments like anti-corrosion coatings or varnishing enhance durability, while plain or beveled ends facilitate easy installation. Compared to other low-alloy steels, 25MnG provides a cost-effective solution with superior strength and corrosion resistance.

These tubes excel in environments requiring resistance to wear, corrosion, and thermal fatigue. Their seamless construction ensures uniform strength, making them suitable for complex industrial piping systems. Whether used in high-temperature boiler systems or corrosive petrochemical applications, GB 5310 25MnG seamless boiler tubes deliver unmatched durability, safety, and performance, addressing critical challenges like pipeline wear and thermal stress in industrial processes.

Tensile strength of 485–640 MPa for high-pressure reliability.

Enhanced resistance to steam and water corrosion.

Handles up to 510°C for heating surfaces.

Eliminates weak points for enhanced safety.

Weldable without preheating for easy installation.

Durable and efficient for high-pressure applications.

| Feature | GB 5310 25MnG | GB 5310 20G | GB 5310 15CrMoG |

|---|---|---|---|

| Material Type | Carbon Steel | Carbon Steel | Low-Alloy Steel |

| Temperature Range | ≤510°C (heating surface) | ≤450°C (heating surface) | ≤540°C (superheater) |

| Tensile Strength (MPa) | 485–640 | 410–550 | 440–640 |

| Yield Strength (MPa) | ≥275 | ≥230 | ≥295 |

| Weldability | Good | Good | Moderate |

| Applications | High-pressure boilers | High-pressure boilers | Ultra-supercritical boilers |

| Key Advantage | High strength and toughness | Good plasticity | High creep resistance |

A curated list of long-tail keywords for GB 5310 25MnG seamless boiler tubes, covering specifications, applications, and material properties.

Note: GB 5310 25MnG seamless boiler tubes comply with GB/T 5310-2017 and GB/T 699 standards. For detailed specifications, refer to the standards or contact a certified supplier.

GB 5310 25MnG seamless boiler tubes are critical for high-pressure boiler systems, superheaters, reheaters, and petrochemical applications, offering high strength and reliability.

Used in boilers with pressures ≥9.8 MPa.

Handles temperatures up to 510°C.

Efficient heat transfer in boiler systems.

Reliable for high-pressure steam flow.

Improves boiler efficiency.

Used in high-pressure fluid systems.

Gb 5310 20mng seamless boiler tubes, compliant wit...

Gb 5310 12cr2mog seamless boiler tubes, compliant ...