Seamless Tubes For High-pressure And High-temperature Boilers

Seamless high-pressure boiler tubes for extreme conditions, offering superior corrosion resistance and thermal stability for power plants and petrochemicals.

Seamless Tubes For High-pressure And High-temperature Boilers

Seamless high-pressure boiler tubes for extreme conditions, offering superior corrosion resistance and thermal stability for power plants and petrochemicals.

High-Pressure Boiler Tubes are seamless steel tubes engineered for extreme pressure and temperature environments, offering superior corrosion resistance and thermal stability. Conforming to standards like A192, ASTM A213, and EN 10216-2, these tubes are ideal for power plant boiler tubes, petrochemical boiler piping, and superheater applications in power generation, refineries, and industrial heating systems. Their seamless construction ensures reliability and durability under high-pressure conditions up to 30 MPa and temperatures up to 650°C.

Manufactured through hot-rolling or cold-drawing processes, Seamless High-Pressure Boiler Tubes are available in outer diameters from 10 mm to 219 mm and wall thicknesses from 1 mm to 20 mm. Lengths are offered in standard (6m, 12m) or customized options (up to 30m) to meet specific project needs. Heat treatments such as normalizing, quenching, and tempering enhance mechanical properties, ensuring resistance to pipeline wear and creep under prolonged thermal exposure. The seamless design eliminates weld imperfections, critical for maintaining integrity in supercritical boiler systems.

The chemical composition of high-pressure boiler tubes typically includes carbon (0.05–0.30%), silicon (0.10–1.00%), manganese (0.30–1.20%), phosphorus (≤0.035%), sulfur (≤0.035%), and alloying elements like chromium (0.80–2.60%) and molybdenum (0.44–1.13%) in grades like T11 or T22, enhancing corrosion resistance and high-temperature strength. These tubes undergo rigorous testing, including tensile, hardness, flattening, flaring, and hydrostatic tests, to ensure compliance with ASTM, EN, and JIS standards. Surface treatments like phosphating, varnishing, or FBE coatings protect against corrosion, while plain or beveled ends simplify installation.

High-Pressure Boiler Tubes are essential for applications requiring robust performance, such as supercritical and ultra-supercritical boilers, petrochemical refineries, and high-pressure heat exchangers. Compared to standard boiler tubes, they offer enhanced strength and resistance to extreme conditions, making them suitable for handling superheated steam and corrosive fluids. Their ability to resist oxidation, thermal fatigue, and creep ensures reliable operation in demanding environments, reducing downtime and maintenance costs.

These tubes address critical challenges like high-pressure containment, corrosion, and thermal stress in boiler systems. Their seamless construction, compliance with stringent standards, and advanced alloy compositions make them a reliable choice for engineers seeking durable seamless boiler piping solutions, ensuring safety, efficiency, and extended service life in high-pressure applications.

Handles pressures up to 30 MPa in supercritical boilers.

Performs reliably at temperatures up to 650°C.

Resists oxidation with alloyed grades and coatings.

Eliminates weld defects for leak-proof performance.

Reduces maintenance with long-lasting materials.

Certified with rigorous testing to meet global standards.

| Grade | C (%) | Si (%) | Mn (%) | P (% max) | S (% max) | Cr (%) | Mo (%) |

|---|---|---|---|---|---|---|---|

| ASTM A192 | 0.06–0.18 | 0.25 max | 0.27–0.63 | 0.035 | 0.035 | - | - |

| ASTM A213 T11 | 0.05–0.15 | 0.50–1.00 | 0.30–0.60 | 0.030 | 0.030 | 1.00–1.50 | 0.44–0.65 |

| ASTM A213 T22 | 0.05–0.15 | 0.50 max | 0.30–0.60 | 0.030 | 0.030 | 1.90–2.60 | 0.87–1.13 |

| Grade | Tensile Strength (MPa min) | Yield Strength (MPa min) | Elongation (% min) |

|---|---|---|---|

| ASTM A192 | 325 | 180 | 35 |

| ASTM A213 T11 | 415 | 205 | 30 |

| ASTM A213 T22 | 415 | 205 | 30 |

| Feature | High-Pressure Boiler Tubes | Welded Boiler Tubes | Stainless Steel Tubes |

|---|---|---|---|

| Material Type | Carbon/Alloy Steel | Carbon/Alloy Steel | Stainless Steel |

| Temperature Range | Up to 650°C | Up to 500°C | Up to 800°C |

| Tensile Strength (MPa) | 325–415 | 300–400 | 515–690 |

| Yield Strength (MPa) | 180–205 | 150–200 | 205–345 |

| Corrosion Resistance | Moderate (with coatings) | Moderate (weld areas vulnerable) | Excellent |

| Pressure Resistance | Superior (up to 30 MPa) | Moderate | High |

| Cost | Moderate | Lower | Higher |

| Applications | Supercritical boilers, heat exchangers | Low-pressure boilers | Corrosive, high-temperature systems |

| Key Advantage | Extreme pressure reliability | Cost-effective | Superior corrosion resistance |

| Manufacturing Process | Seamless, heat-treated | Welded (ERW, SAW) | Seamless or welded |

High-pressure boiler tubes are critical for power generation and industrial applications, designed to withstand high temperatures and pressures. Materials are selected for their creep resistance, corrosion resistance, and strength at elevated temperatures, ensuring safety, efficiency, and longevity.

| Material Type | Examples | Composition | Temperature Limit | Applications |

|---|---|---|---|---|

| Carbon Steel | SA178 | Plain carbon steel | Up to 1000°F (540°C) | Low to medium pressure boilers, below 800°F (427°C) for rimmed steel, 1000°F (540°C) for killed steel |

| Carbon-Molybdenum Steel | SA209 | ~0.5% Mo | Up to 1000°F (540°C) | Superheaters, reheaters in high-temperature, high-pressure environments |

| Low Alloy Steel | SA213-T11, T12, T22 | Up to 2.25% Cr, 1% Mo | Up to 1200°F (650°C) | High-pressure boilers; T11/T12 for lower temperatures, T22 for higher creep strength |

| High Alloy Steel | SA213-T9, T91 | Up to 9% Cr, 1% Mo | Up to 1200°F (650°C) | Superheaters, reheaters in high-pressure boilers |

| Stainless Steel | SA213-TP304, TP316 | Austenitic, high Cr/Ni | Up to 1200°F (650°C) | Superheaters, reheaters requiring high corrosion resistance |

| Superalloys | Inconel, Hastelloy | Nickel-based | Up to 1800°F (980°C) | Supercritical/ultra-supercritical boilers, extreme conditions |

Note: Material selection depends on operating conditions (temperature, pressure, corrosion). Proper choice ensures boiler safety and efficiency.

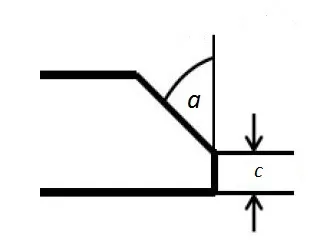

Tube ends are vertical to the longitudinal axis and burr-free.

| Parameter | Specification |

|---|---|

| Tube OD | 26.7–114.3 mm |

| Tube WT | 3.2–12.5 mm |

| Tube Lengths | 4–13 meters |

| Deburring Angle (a) | 30° ± 5° or 37° ± 2.5° |

| Dimension (c) | 1.6 ± 0.8 mm |

Tubes have deburred ends or are customized for welding.

Note: Images of tube ends are available upon request from suppliers.

Ensured through dimensional examination, visual checks, chemical composition, mechanical properties, and 100% eddy current testing.

Hot gas passes through tubes in a sealed water container, transferring heat to generate steam.

Water circulates in tubes heated externally by fire, producing steam in a steam drum.

Explore high-pressure boiler tubes with targeted long-tail keywords, covering specifications, applications, manufacturing, procurement, and dimensions for extreme boiler systems.

Note: High-pressure boiler tubes are tailored for extreme conditions. For detailed specifications, refer to ASTM A192, A213, EN 10216-2, or contact a certified supplier.

High-Pressure Boiler Tubes are critical for extreme pressure and temperature applications in power generation, petrochemicals, and industrial heating systems.

Handles ultra-high-pressure steam in power plants.

Resists corrosion in high-temperature processing.

Ensures efficient heat transfer in industrial systems.

Manages superheated steam in power generation.

Supports high-pressure steam in heating systems.

Used in high-pressure fluid transport systems.

Note:

We are continuously updating our product list. If you can't find

what you're looking for, please try searching for other products.