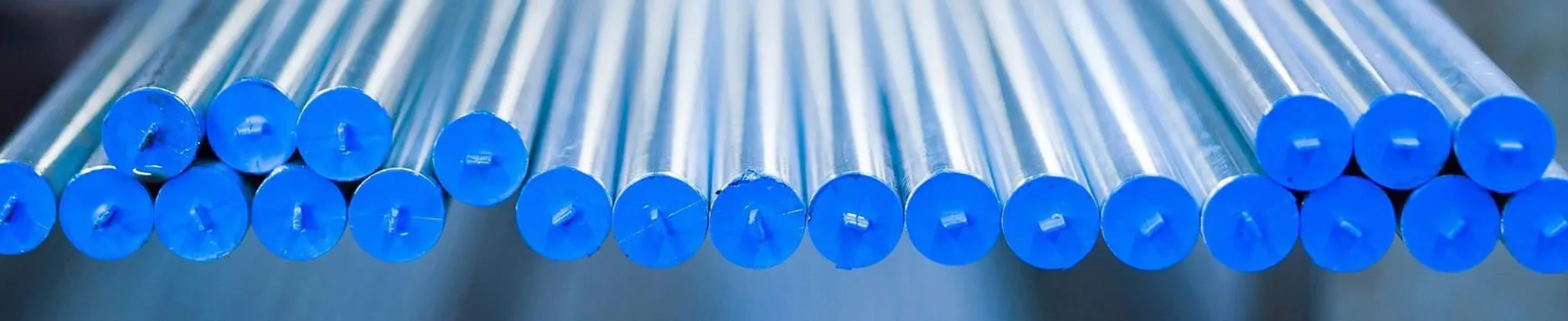

Seamless Zinc-coated Tubes For Enhanced Corrosion Resistance

Galvanized hydraulic tubes offer superior corrosion resistance and durability for high-pressure hydraulic systems in industrial applications.

Seamless Zinc-coated Tubes For Enhanced Corrosion Resistance

Galvanized hydraulic tubes offer superior corrosion resistance and durability for high-pressure hydraulic systems in industrial applications.

Galvanized Hydraulic Tubes are precision-engineered seamless steel tubes coated with a protective zinc layer, designed for hydraulic steel tubes and pneumatic systems. These tubes are manufactured to standards such as DIN 2391, EN 10305-1, and ASTM A519, offering exceptional corrosion resistance and durability. The zinc coating, applied through hot-dip or electro-galvanizing, protects against rust, making them suitable for demanding applications in construction, automotive, and industrial machinery.

Produced via cold-drawing processes, Seamless Hydraulic Tubes achieve tight dimensional tolerances (H8–H10) and a smooth surface finish (Ra ≤ 0.8 µm), ensuring efficient fluid flow and compatibility with hydraulic components. Available in outer diameters from 4 mm to 130 mm and wall thicknesses from 0.5 mm to 12 mm, they are designed for high-pressure systems (up to 100 MPa). The galvanization process enhances longevity by preventing corrosion in environments exposed to moisture or chemicals, though care must be taken to ensure compatibility with hydraulic fluids to avoid zinc flaking

Galvanized Hydraulic Tubes address challenges like pipeline wear, corrosion, and pressure fluctuations in hydraulic systems. Their seamless construction and zinc coating make them a reliable choice for engineers seeking durable corrosion resistant tubes for extreme environments.

When producing galvanized steel tubes, we use no-oxygen furnace to annealed the tubes which ensuire the smoothness of the inner and outside surface.

Both the inner and outer surfaces of the high precision steel tubes can be galvanized or Zn only coated to the outside diameter,giving the tube a high homogeneity and an excellent rust resistant performance.

Galvanized hydraulic tubes are engineered to meet stringent requirements for high-pressure applications:

These specifications ensure compatibility with hydraulic fittings, valves, and flanges, making the tubes ideal for high-pressure fluid transmission.

Roller-burnished tubes offer precision bore and du...