Corrosion-resistant And Cost-effective Piping Solutions

Galvanized mild steel pipes offer corrosion resistance and durability for water supply, construction, and industrial applications.

Corrosion-resistant And Cost-effective Piping Solutions

Galvanized mild steel pipes offer corrosion resistance and durability for water supply, construction, and industrial applications.

Galvanized Mild Steel Pipes are low-carbon steel pipes coated with a zinc layer through hot-dip or electro-galvanizing processes, offering excellent corrosion resistance and durability. Compliant with ASTM A53 and A123 standards, these pipes are ideal for water supply systems, construction frameworks, and agricultural irrigation, providing a minimum tensile strength of 330 MPa and a zinc coating thickness of at least 1.2 oz/ft² (366 g/m²).

The galvanizing process involves cleaning, pickling, and immersing the mild steel pipes in molten zinc at approximately 450°C (842°F) for hot-dip galvanizing, or applying zinc via electroplating for electro-galvanized pipes, creating a protective layer against rust. Available in sizes from DN15 (1/2”) to DN200 (8”) with wall thicknesses from SCH 40 to SCH 80, and lengths from 5.8 to 12 meters, Galvanized Mild Steel Pipes meet diverse project needs. Surface treatments like passivation enhance longevity, and plain or threaded ends facilitate easy installation.

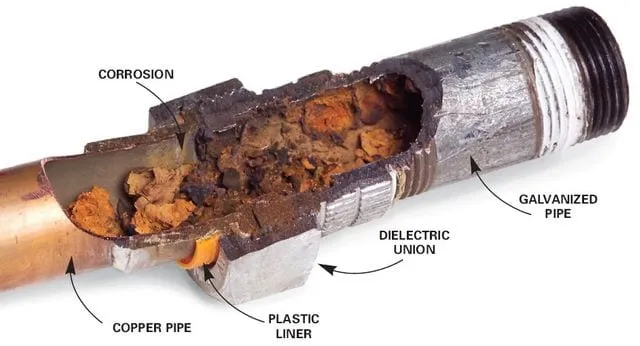

These pipes undergo rigorous testing, including tensile, hydrostatic, and coating thickness tests, to ensure compliance with ASTM standards. The zinc coating acts as a sacrificial anode, protecting the mild steel even if scratched, making Corrosion-Resistant Mild Steel Pipes suitable for humid and industrial environments. Their strength supports high-pressure applications in gas pipelines and industrial piping.

Compared to stainless steel or pre-galvanized pipes, Galvanized Mild Steel Pipes offer a cost-effective solution with good corrosion resistance, though they may require maintenance in highly corrosive environments. Their versatility and lifespan (up to 40 years) make them a preferred choice for fencing, railings, and structural applications.

Galvanized Mild Steel Pipes address challenges like pipeline corrosion, environmental exposure, and cost constraints, delivering reliable, long-lasting solutions for industrial and residential applications.

Mild Steel Pipe Galvanized is a tubular-shaped pipe of galvanized Mild Steel. Galvanized pipes are commonly used in plumbing and fencing since they provide reliable performance and longevity.

Hot-dip galvanizing is the process of coating iron or steel with a thin zinc layer, by passing the steel through a molten bath of zinc at a temperature of around 860 °F (460 °C). When exposed to the atmosphere, pure zinc reacts with oxygen to form zinc oxide. This further reacts with carbon dioxide to form zinc carbonate, a dull grey, fairly strong material that stops further corrosion in many circumstances, protecting the steel below from the elements. Galvanized steel is widely used in applications where rust resistance is needed, and can be identified by the crystallization patterning on the surface (often called a “spangle”).

| Stock Description | Weight (KG/M) |

|---|---|

| 21.40 x 2.0mm | 0.957 |

| 25.00 x 2.0mm | 1.154 |

| 26.99 x 2.0mm | 1.233 |

| 31.75 x 2.0mm | 1.467 |

| 34.10 x 2.0mm | 1.583 |

| 38.10 x 2.0mm | 1.780 |

| 42.86 x 2.0mm | 2.015 |

| 48.50 x 2.0mm | 2.293 |

| 50.80 x 2.0mm | 2.407 |

| 60.33 x 2.0mm | 2.877 |

| 76.20 x 2.0mm | 3.660 |

| 101.60 x 2.0mm | 4.912 |

The properties of galvanized steel are a unique combination that make it ideal for use in interior and exterior applications such as car bodies, appliances, nuts and bolts, roofs, and rebar.

| Grade | C (% max) | Mn (% max) | P (% max) | S (% max) | Cu (% max) |

|---|---|---|---|---|---|

| Grade A | 0.25 | 0.95 | 0.05 | 0.045 | 0.40 |

| Grade B | 0.30 | 1.20 | 0.05 | 0.045 | 0.40 |

The zinc coating (80-100 microns) enhances the corrosion resistance of Galvanized Mild Steel Pipe , protecting the carbon steel base in harsh environments. The chemical composition ensures weldability and durability for

| Grade | Tensile Strength (min, MPa) | Yield Strength (min, MPa) | Elongation (min, %) |

|---|---|---|---|

| Grade A | 330 | 205 | 28 |

| Grade B | 415 | 240 | 30 |

These properties ensure Galvanized Mild Steel Pipe eliver robust performance in structural and high-pressure applications.

| Feature | Hot-Dip Galvanized Pipe | Pre-Galvanized Pipe | Stainless Steel Pipe |

|---|---|---|---|

| Coating | Zinc (80-100 microns) | Zinc (thinner, coil-coated) | None (inherent corrosion resistance) |

| Corrosion Resistance | Excellent (sacrificial anode) | Moderate (weaker at welds) | Superior (no coating needed) |

| Cost | Cost-effective | Lower initial cost | Higher cost |

| Lifespan | Up to 50 years | 20-30 years | 50+ years |

| Applications | Water, gas, construction | Light structural, fencing | Chemical, marine, hygienic |

Hot-Dip Galvanized Pipes offer distinct advantages over pre-galvanized and stainless steel pipes.

| Grade | C (% max) | Mn (% max) | Si (% max) | P (% max) | S (% max) | Cr (%) | Ni (%) | Mo (%) | N (% max) |

|---|---|---|---|---|---|---|---|---|---|

| 304 | 0.08 | 2.00 | 1.00 | 0.045 | 0.030 | 18.0-20.0 | 8.0-11.0 | - | 0.10 |

| 304L | 0.03 | 2.00 | 1.00 | 0.045 | 0.030 | 18.0-20.0 | 8.0-12.0 | - | 0.10 |

| 316 | 0.08 | 2.00 | 1.00 | 0.045 | 0.030 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 | 0.10 |

| 316L | 0.03 | 2.00 | 1.00 | 0.045 | 0.030 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 | 0.10 |

The low carbon content in 304L and 316L enhances weldability, while molybdenum in 316 and 316L improves resistance to pitting and crevice corrosion, making Galvanized Mild Steel Pipe ideal for harsh environments.

| Grade | Tensile Strength (min, MPa) | Yield Strength (min, MPa) | Elongation (min, %) | Hardness (max, HB) | Hardness (max, HRB) |

|---|---|---|---|---|---|

| 304 | 515 | 205 | 40 | 201 | 92 |

| 304L | 485 | 170 | 40 | 201 | 92 |

| 316 | 515 | 205 | 40 | 217 | 95 |

| 316L | 485 | 170 | 40 | 217 | 95 |

These mechanical properties make Galvanized Mild Steel Pipe suitable for applications requiring high strength and corrosion resistance, such as architectural structures, marine environments, and chemical processing.

Galvanized seamless tubes are widely used in various industries, including construction, plumbing, automotive, and infrastructure projects.

Galvanized seamless tubes offer corrosion resistan...

Erw galvanized steel pipes offer corrosion resista...

Pre-galvanized steel pipes offer cost-effective co...

Galvanized pipes for water offer corrosion resista...

Hot-dip galvanized square tubes offer corrosion re...