Corrosion-resistant And Durable Structural Solutions

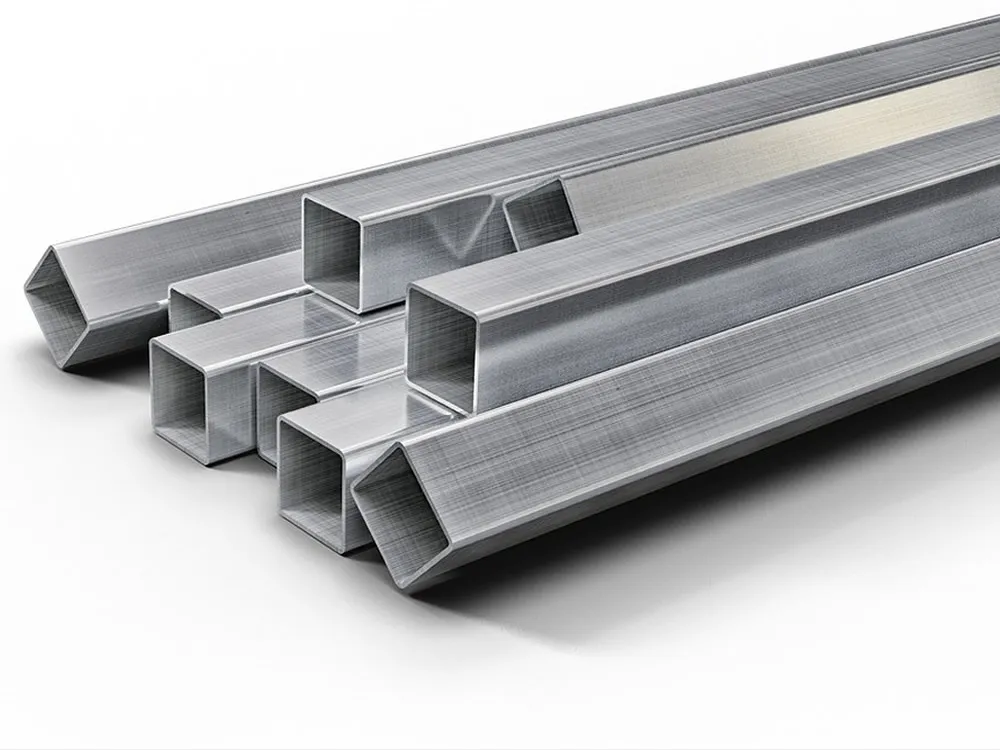

Hot-dip galvanized square tubes offer corrosion resistance and durability for structural frameworks, fencing, and industrial applications.

Corrosion-resistant And Durable Structural Solutions

Hot-dip galvanized square tubes offer corrosion resistance and durability for structural frameworks, fencing, and industrial applications.

Hot-Dip Galvanized Square Tubes are carbon steel tubes with a square cross-section, coated with a zinc layer through a hot-dip galvanizing process, ensuring superior corrosion resistance and durability. Compliant with ASTM A123 and A500 standards, these tubes are ideal for structural frameworks, fencing, and agricultural structures, offering a minimum tensile strength of 400 MPa and a zinc coating thickness of at least 1.5 oz/ft² (458 g/m²).

The manufacturing process involves forming steel strips into square tubes via electric resistance welding (ERW) or seamless methods, followed by immersion in molten zinc at approximately 450°C (842°F), creating a metallurgical bond that protects against rust. Available in sizes from 15x15 mm to 200x200 mm with wall thicknesses from 1.2 to 8.0 mm, and lengths from 6 to 12 meters, Hot-Dip Galvanized Square Tubes meet diverse project requirements. Surface treatments like passivation enhance longevity, and pre-cut or custom lengths facilitate easy installation.

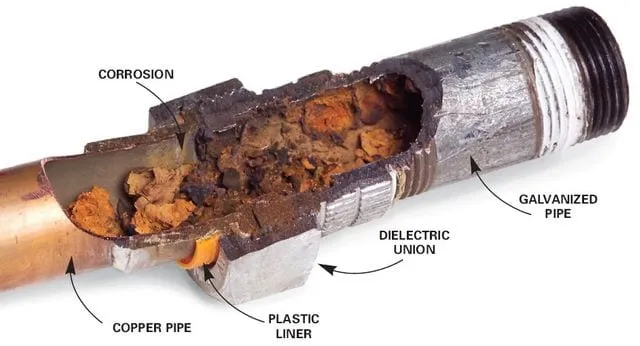

These tubes undergo rigorous testing, including tensile, bending, and coating thickness tests, to ensure compliance with ASTM standards. The zinc coating acts as a sacrificial anode, protecting the steel even if scratched, making Corrosion-Resistant Square Tubes suitable for harsh environments like coastal and industrial settings. Their square shape provides enhanced structural stability for applications like scaffolding and piping supports.

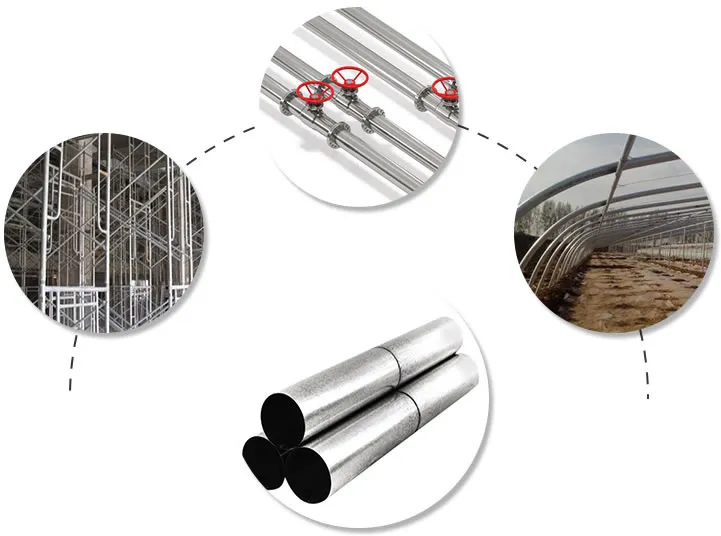

Compared to non-galvanized square tubes or stainless steel tubes, Hot-Dip Galvanized Square Tubes offer superior corrosion protection and cost-effectiveness, though they may require periodic maintenance in highly corrosive environments. Their versatility and lifespan (up to 50 years) make them a preferred choice for greenhouse frames and structural applications.

Hot-Dip Galvanized Square Tubes address challenges like corrosion, environmental exposure, and structural integrity, delivering reliable, long-lasting solutions for industrial and agricultural applications.

Hot-dipped galvanized square tubing is an excellent candidate for most processing techniques. Welding, torching, or abrasive sawing galvanized steel is not recommended without proper protection and adequate ventilation. Galvanized square tubes are hot rolled steel, or mild steel, tubes that have dipped into a molten zinc coating process. Hot-dipped galvanize (HDG) can be identified by its crystallization pattern, also known as “spangle” on the surface of the material. Great corrosion resistance, excellent candidate for outdoor use or exposed environments. Common applications include structural support, outdoor signs, docks, trailers, sign posts and framing.

| Size | OD | Wall Thickness | Length | Weight (Lb/Ft) |

|---|---|---|---|---|

| 1-1/2" x 1-1/2" x 12ga | 1-1/2 x 1-1/2" | 12ga | 288.00" | 2.062 |

| 1-3/4" x 1-3/4" x 12ga | 1-3/4 x 1-3/4" | 12ga | 288.00" | 2.603 |

| 2" x 2" x 12ga | 2 x 2" | 12ga | 288.00" | 2.958 |

Galvanized Hydraulic Tube Advantages

Buyers very like 4 inch square tubing. Making pre galvanized 4 inch square tubing by directly rolling galvanized coils into shape.

The surface of pre galvanized 4 inch square tubing is smoother and more attractive. Due to galvanizing, it also greatly increases the lifespan of steel pipes. so the pre galvanized 4 inch square tubing is used for many industries.

| Coating | Outer Diameter (inch) | W.T. (mm) | Length (M) | Zinc Layer | Standard | Grade |

|---|---|---|---|---|---|---|

| bare | 4"×4" | 0.5-16 | 0.5-26.5 | No zinc coating | ASTM A500/A501, EN10219/10210, JIS G3466, GB/T6728/3094, AS1163, CSA G40.20/G40.21 | Gr.A/B/C, S235/275/355/420/460, A36, SS400, Q195/235/355, STKR400/490, 300W/350W |

| galvanized square tubing | 4"×4" | 1-16 | 0.5-26.5 | Ordinary galvanizing: usually between 45-500 micrometers (μ m) | ASTM A500/A501, EN10219/10210, JIS G3466, GB/T6728/3094, AS1163, CSA G40.20/G40.21 | Gr.A/B/C, S235/275/355/420/460, A36, SS400, Q195/235/355, STKR400/490, 300W/350W |

The properties of galvanized steel are a unique combination that make it ideal for use in interior and exterior applications such as car bodies, appliances, nuts and bolts, roofs, and rebar.

| Grade | C (% max) | Mn (% max) | P (% max) | S (% max) | Cu (% max) |

|---|---|---|---|---|---|

| Grade A | 0.25 | 0.95 | 0.05 | 0.045 | 0.40 |

| Grade B | 0.30 | 1.20 | 0.05 | 0.045 | 0.40 |

The zinc coating (80-100 microns) enhances the corrosion resistance of Hot-Dip Galvanized Square Tube , protecting the carbon steel base in harsh environments. The chemical composition ensures weldability and durability for

| Grade | Tensile Strength (min, MPa) | Yield Strength (min, MPa) | Elongation (min, %) |

|---|---|---|---|

| Grade A | 330 | 205 | 28 |

| Grade B | 415 | 240 | 30 |

These properties ensure Hot-Dip Galvanized Square Tube eliver robust performance in structural and high-pressure applications.

| Feature | Hot-Dip Galvanized Pipe | Pre-Galvanized Pipe | Stainless Steel Pipe |

|---|---|---|---|

| Coating | Zinc (80-100 microns) | Zinc (thinner, coil-coated) | None (inherent corrosion resistance) |

| Corrosion Resistance | Excellent (sacrificial anode) | Moderate (weaker at welds) | Superior (no coating needed) |

| Cost | Cost-effective | Lower initial cost | Higher cost |

| Lifespan | Up to 50 years | 20-30 years | 50+ years |

| Applications | Water, gas, construction | Light structural, fencing | Chemical, marine, hygienic |

Hot-Dip Galvanized Pipes offer distinct advantages over pre-galvanized and stainless steel pipes.

| Grade | C (% max) | Mn (% max) | Si (% max) | P (% max) | S (% max) | Cr (%) | Ni (%) | Mo (%) | N (% max) |

|---|---|---|---|---|---|---|---|---|---|

| 304 | 0.08 | 2.00 | 1.00 | 0.045 | 0.030 | 18.0-20.0 | 8.0-11.0 | - | 0.10 |

| 304L | 0.03 | 2.00 | 1.00 | 0.045 | 0.030 | 18.0-20.0 | 8.0-12.0 | - | 0.10 |

| 316 | 0.08 | 2.00 | 1.00 | 0.045 | 0.030 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 | 0.10 |

| 316L | 0.03 | 2.00 | 1.00 | 0.045 | 0.030 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 | 0.10 |

The low carbon content in 304L and 316L enhances weldability, while molybdenum in 316 and 316L improves resistance to pitting and crevice corrosion, making Hot-Dip Galvanized Square Tube ideal for harsh environments.

| Grade | Tensile Strength (min, MPa) | Yield Strength (min, MPa) | Elongation (min, %) | Hardness (max, HB) | Hardness (max, HRB) |

|---|---|---|---|---|---|

| 304 | 515 | 205 | 40 | 201 | 92 |

| 304L | 485 | 170 | 40 | 201 | 92 |

| 316 | 515 | 205 | 40 | 217 | 95 |

| 316L | 485 | 170 | 40 | 217 | 95 |

These mechanical properties make Hot-Dip Galvanized Square Tube suitable for applications requiring high strength and corrosion resistance, such as architectural structures, marine environments, and chemical processing.

Galvanized seamless tubes are widely used in various industries, including construction, plumbing, automotive, and infrastructure projects.

Galvanized seamless tubes offer corrosion resistan...

Erw galvanized steel pipes offer corrosion resista...

Pre-galvanized steel pipes offer cost-effective co...

Galvanized mild steel pipes offer corrosion resist...

Galvanized pipes for water offer corrosion resista...