Thin, Durable Wear-resistant Panel

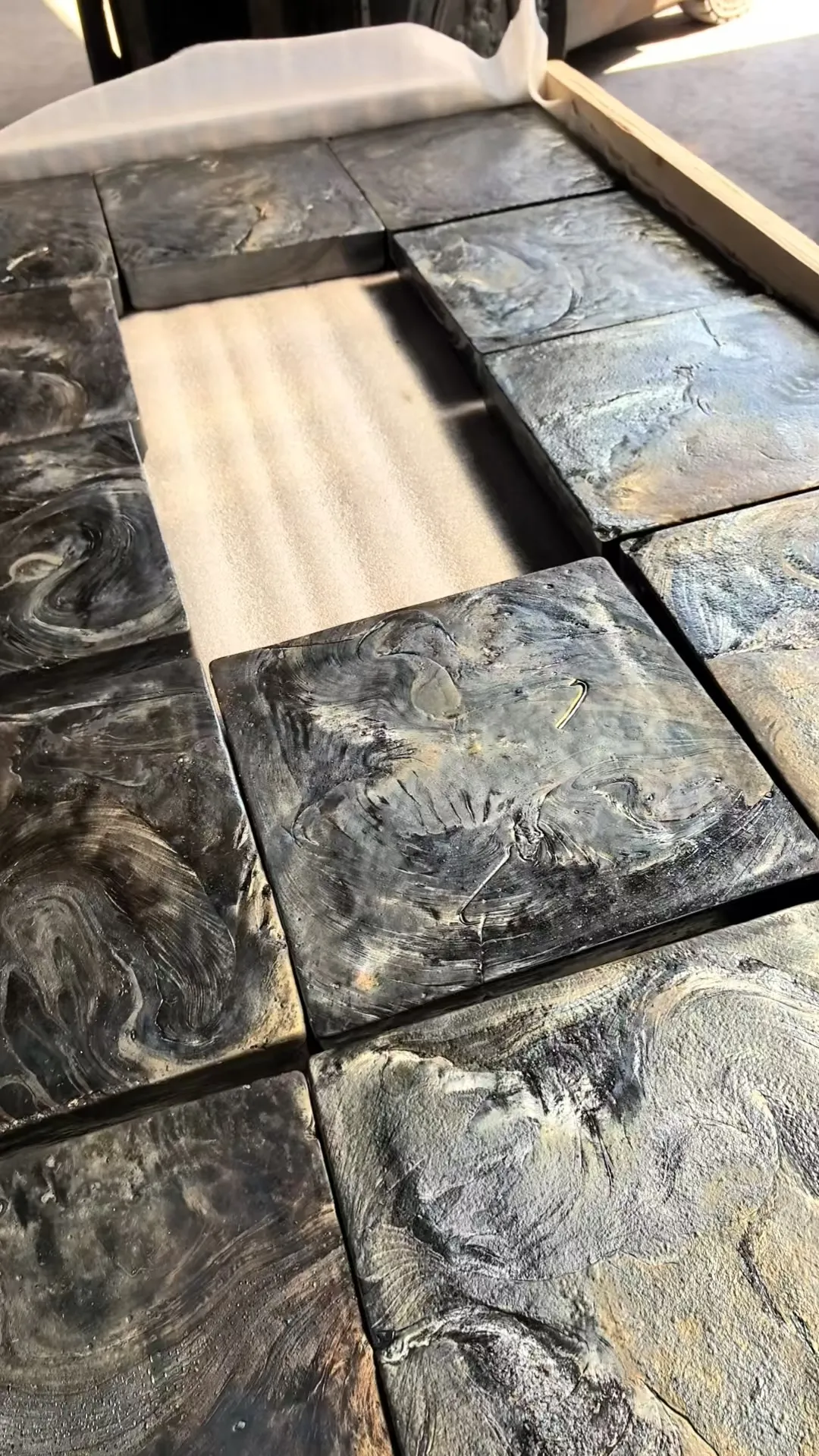

High-performance ultrathin basalt tiles offering excellent abrasion and chemical resistance with reduced thickness for flexible industrial linings.

Thin, Durable Wear-resistant Panel

High-performance ultrathin basalt tiles offering excellent abrasion and chemical resistance with reduced thickness for flexible industrial linings. ultrathin cast basalt tiles deliver durable abrasion and corrosion resistance in a slim profile, ideal for retrofits and limited-space industrial lining applications.

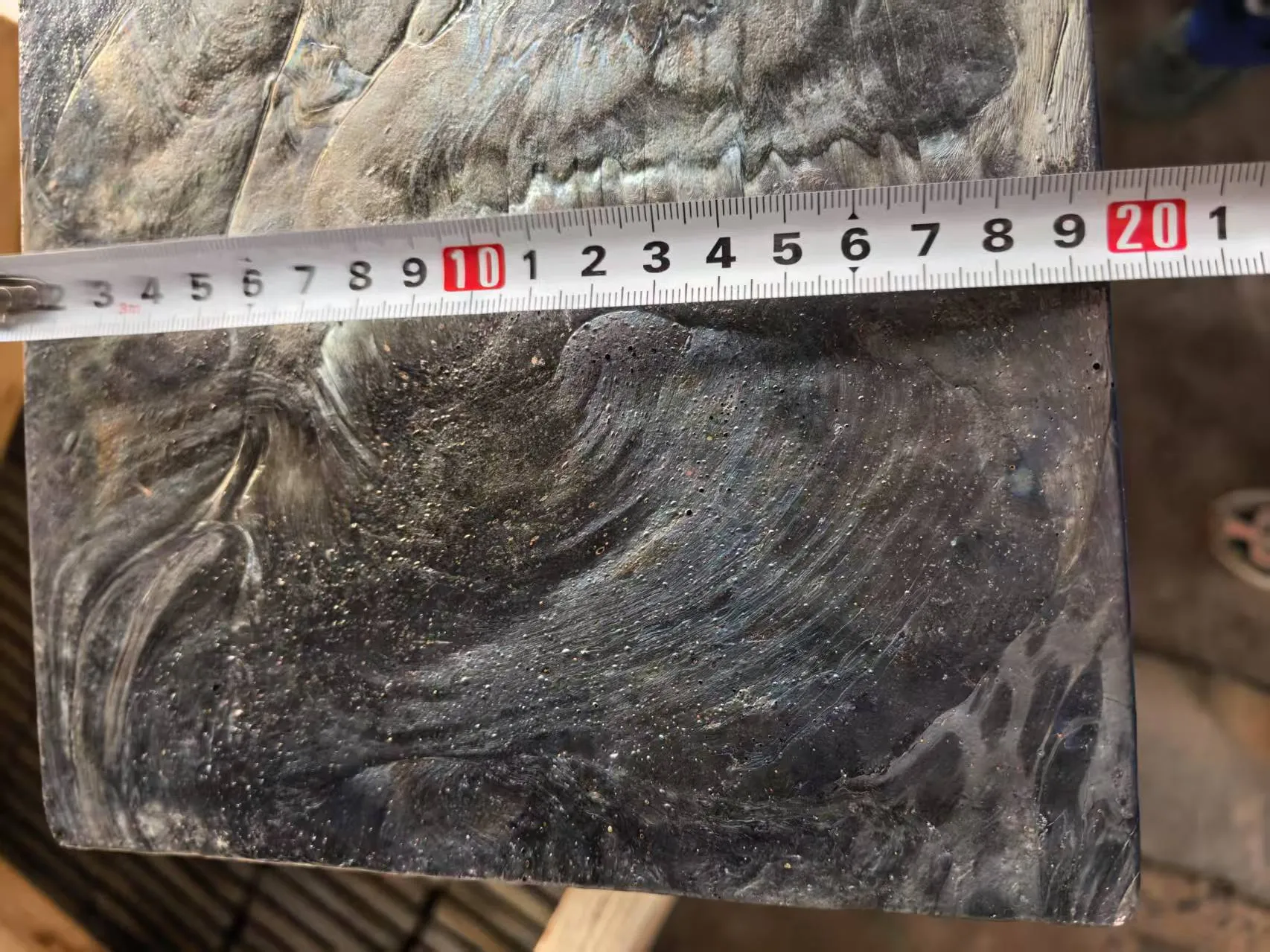

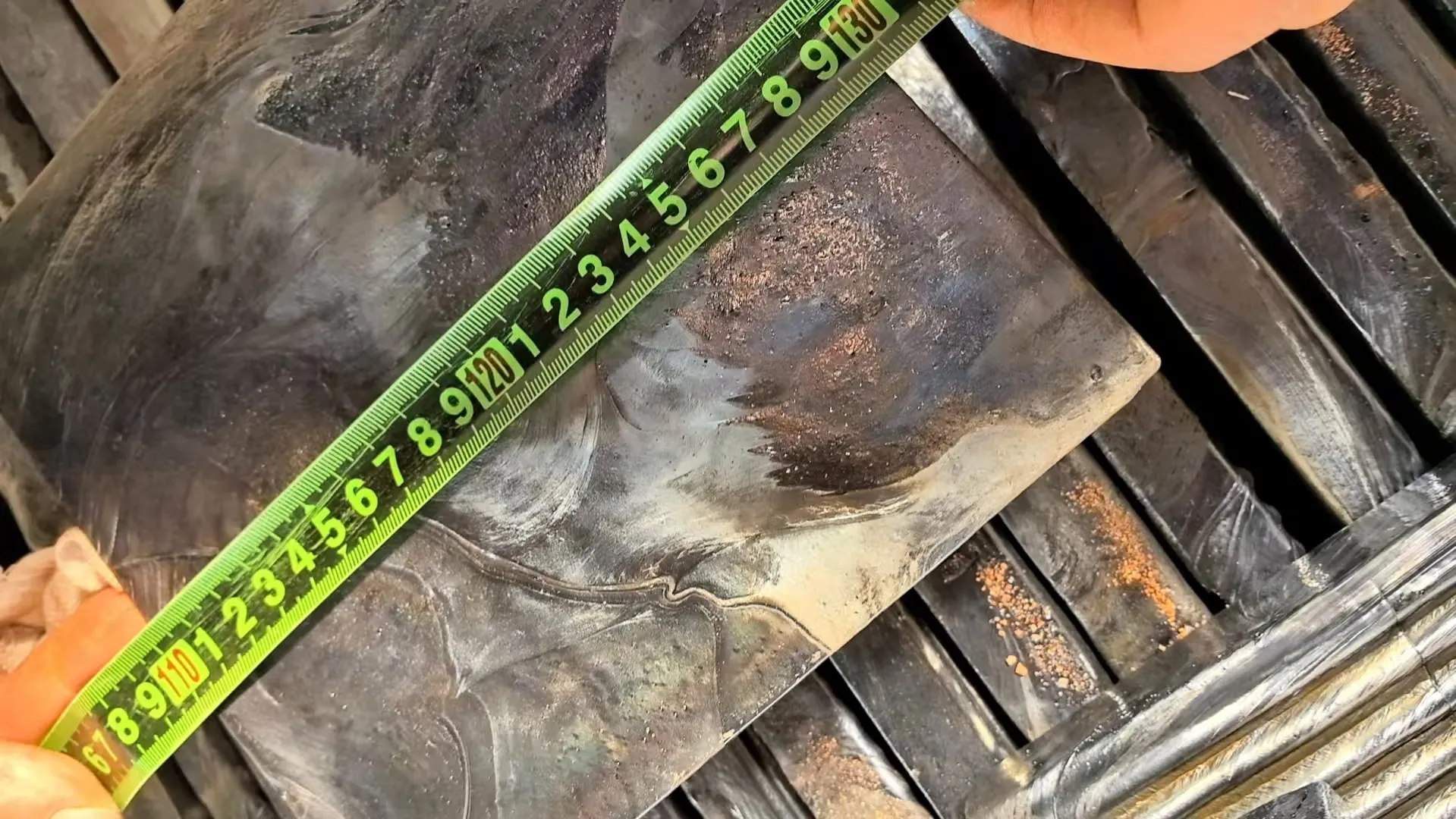

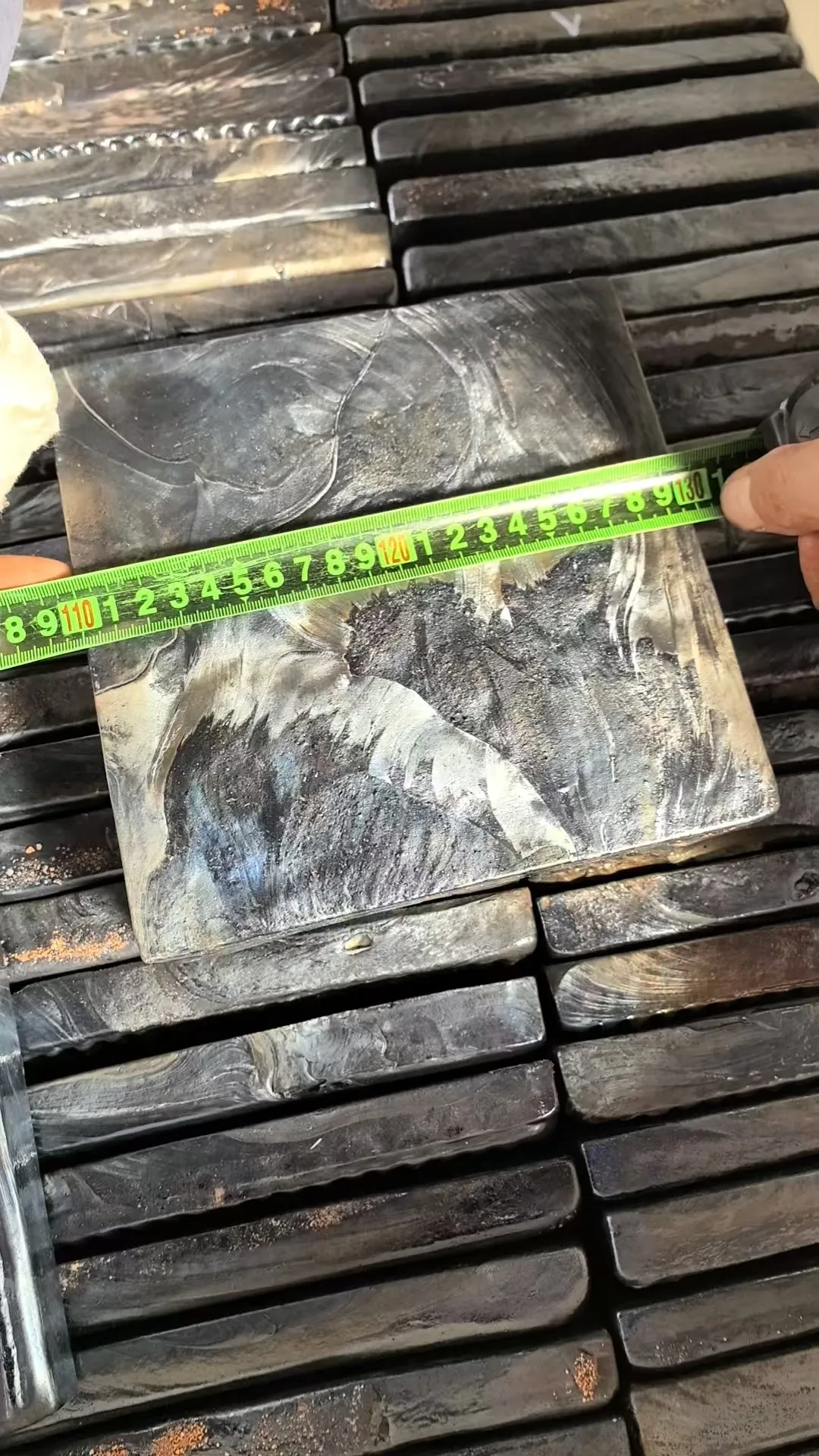

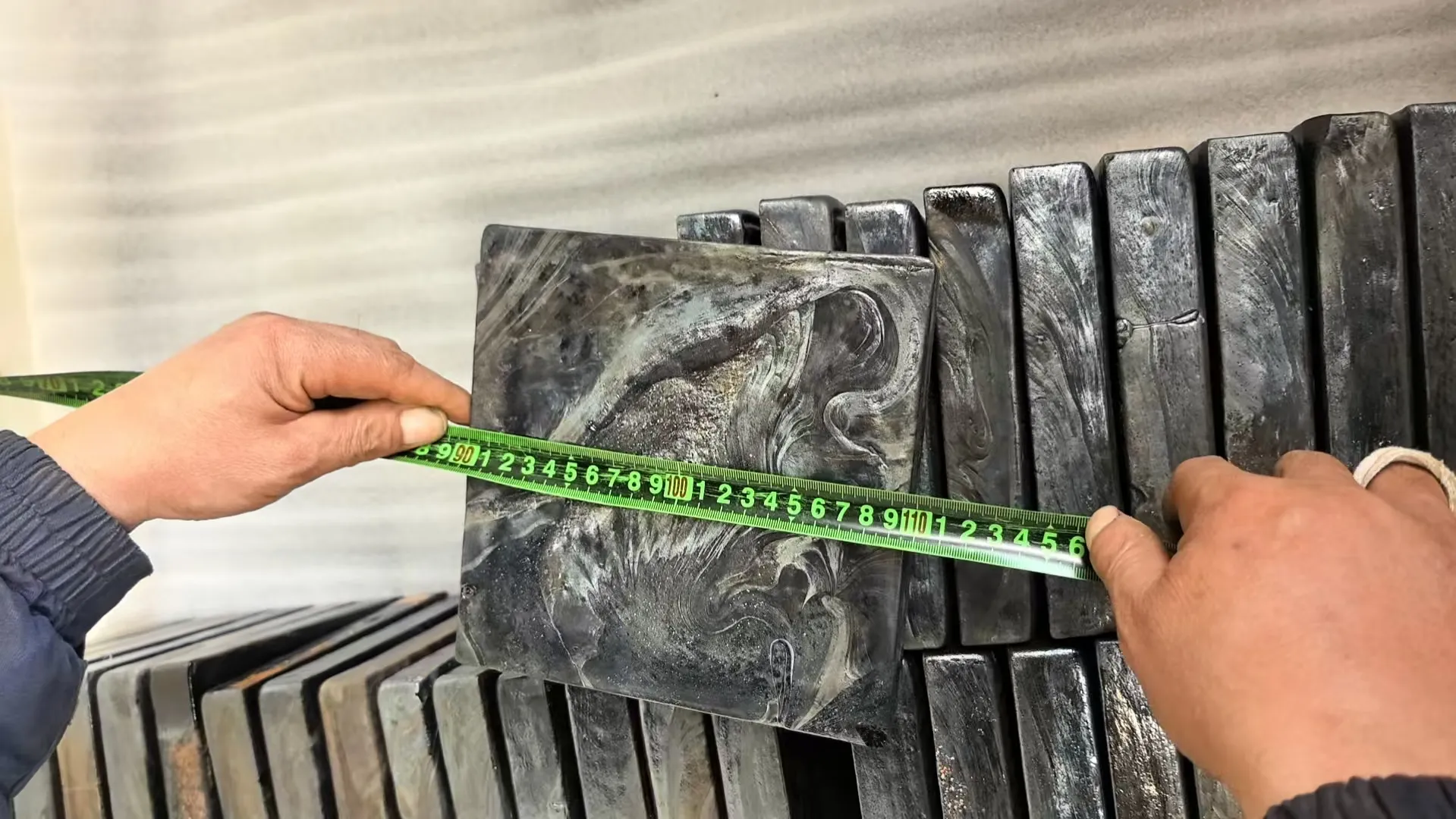

Ultrathin cast basalt tiles are engineered industrial lining panels cast from natural basalt but manufactured with reduced thickness, typically between 8 and 15 mm. Despite their slim profile, these tiles retain the superior wear, chemical, and thermal resistance properties of traditional cast basalt.

Ultrathin cast basalt tiles offer a practical, high-performance solution for industrial lining upgrades where space and weight are critical. Sunny Steel provides full support from product selection to installation for optimal protection and long service life.

Ultra-thin cast basalt tile is a type of construction material made from basalt rock that has been melted and then cast into thin, flat tiles. This process involves pouring molten basalt into a mold and then allowing it to cool and solidify into the desired shape.

Ultra-thin cast basalt tiles are known for their exceptional strength, durability, and resistance to wear and tear. These tiles can be used in a variety of applications, including flooring, countertops, wall cladding, and exterior façade systems.

Features and benefits of ultra-thin cast basalt tiles include:

Ultra-thin cast basalt tile is a high-performance building material made from basalt rock that is cast into thin, flat tiles. These tiles offer several advantages such as exceptional durability, heat and corrosion resistance, lightweight, low-maintenance, and an aesthetically pleasing appearance. They are commonly used in a variety of applications in construction projects that require a cost-effective, yet high-performance building material.

Cast basalt tiles are produced by remelting natural volcanic rock at extremely high temperatures and recrystallising it under controlled conditions — creating one of the hardest and most abrasion-resistant industrial lining materials available.

High-quality natural volcanic basalt rock is carefully selected and crushed into fragments typically 20–50 mm in size. Premium cast basalt uses 100% pure basalt with no additives.

The crushed basalt is fed into a shaft furnace (gas or electric) and melted at 1,250–1,500°C (usually ~1,300°C) until it becomes a fully liquid, lava-like melt.

The molten basalt is poured into preheated metal or sand molds to form tiles (square, hexagonal, rectangular), cylinders, or custom shapes. Thickness is typically 20–50 mm. The back side is often textured for better bonding.

After initial cooling, the still-hot castings are carefully removed from the molds while maintaining thermal control to prevent cracking.

Castings undergo a precisely controlled slow cooling process (16–48 hours) in an annealing furnace. This allows uniform devitrification and formation of fine spherulitic crystals, resulting in Mohs hardness ~8 and abrasion resistance 10–30× greater than steel.

Tiles can be cut, ground, drilled, or polished as required. During cooling, the surface naturally develops a unique glass-like, iridescent patina that is characteristic of cast basalt.

The result is an extremely dense, non-porous material with near-zero water absorption, exceptional chemical resistance, and service life many times longer than steel, rubber, or conventional ceramics in abrasive environments.

Inspection cast basalt tiles offer excellent abrasion, chemical, and impact resistance, ensuring long service life for floors, chutes, and lining surfaces.

Inspection cast basalt tiles are high-performance ceramic tiles made from natural volcanic rock that has been melted and cast into precise shapes. After controlled cooling, the material forms a crystalline structure with exceptional hardness (Mohs 8), high compressive strength, and outstanding chemical stability.

Used for Automotive Brake Testing Grounds

Everything you need to know about Basalt Tiles

Basalt is the new miracle fire-protection material. It is made from volcanic rock and can withstand 2500 degrees for an unlimited time while having 3 times the tensile strength of steel.

Compared with traditional concrete, basalt-fiber-reinforced concrete has the advantages of higher tensile strength and less cracking.

Cast Basalt is a naturally occurring basalt-rock wear-resistant material. Offering superb abrasion resistance, this mineral is quarried, melted, cast, and annealed to form a fine-crystallized glass-ceramic of extreme hardness that resists erosion. Cast Basalt is supplied in pipe and tile form and provides an excellent hard-wearing surface for corrosive wear and abrasion protection of equipment.

Cast basalt tiles are known for their excellent wear resistance and are commonly used in applications where abrasion and corrosion resistance are critical, such as in pipelines, chutes, hoppers, and other high-wear environments. Having these tiles in stock allows for a quick response to customer demands and efficient fulfillment of orders.

Hard & Compact Smooth & Inner Withstands High-Abrasion & Corrosion In any of the process industries especially Sled and Cement corrosion and abrasion lead to significant downtime of the plant. Further, the useful life or the equipment itself may get impaired because of the high abrasive nature of the materials being used. Thus, ‘wear mechanism’ results in hut down, replacement, etc., which is costly, resulting in loss to tilt: tunic of millions of dollars.

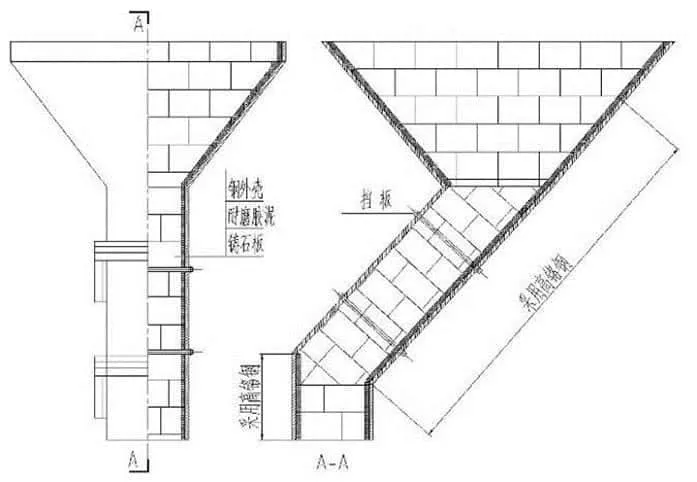

Basalt tiles can be placed and jointed in cement or specially-defined bonding agents, as demanded by the intended application. Basalt tiles can be provided with a central hole that is countersunk for individual bolting, or as ready-made liner plates and pipes.

Cast basalt tiles are mainly used in thermal power plants, steel mills, mines and other parts with heavy wear, such as raw coal bunkers, mine bins, coal unloading trenches, hoppers, ore troughs, flotation machines, chutes and other parts.

Used for Automotive Brake Testing Grounds

These very hard tiles are made for heavy industrial applications but also feature a beautiful metallic sheen. Originally used for sewerage systems or piping pieces, these pavement tiles are made by melting natural basalt and casting it into metal moulds.

Cast basalt lining for ducts and pipes

Sort:0

Sort:0