Externally Hardfaced Abrasion Resistant Tubes

Premium od-clad externally hardfaced abrasion resistant tubes with carbide-rich outer layer (>800 hv hardness).

Externally Hardfaced Abrasion Resistant Tubes

Premium od-clad externally hardfaced abrasion resistant tubes with carbide-rich outer layer (>800 hv hardness).

Superior External Wear Protection with Customized Carbide-Rich Hardfacing

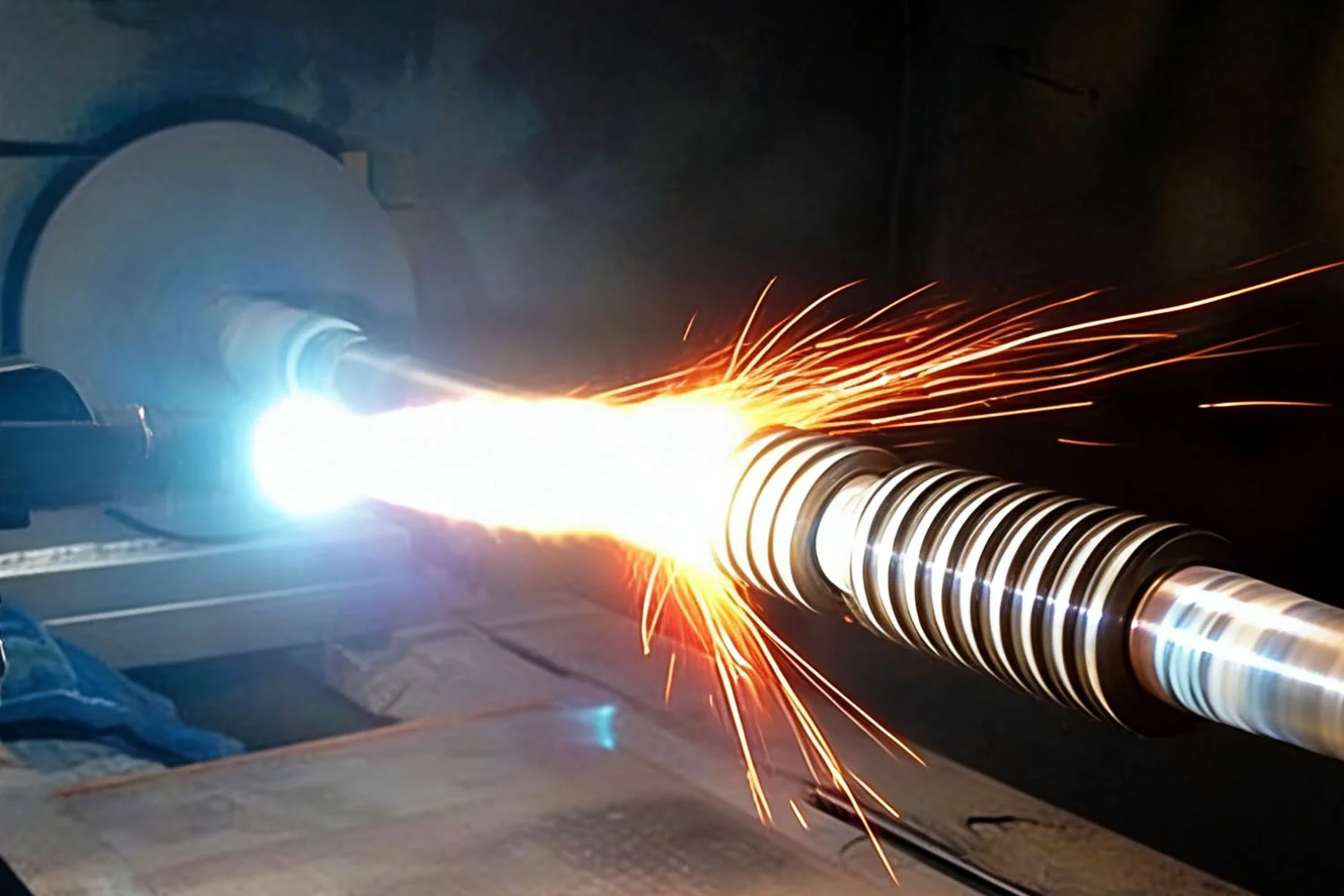

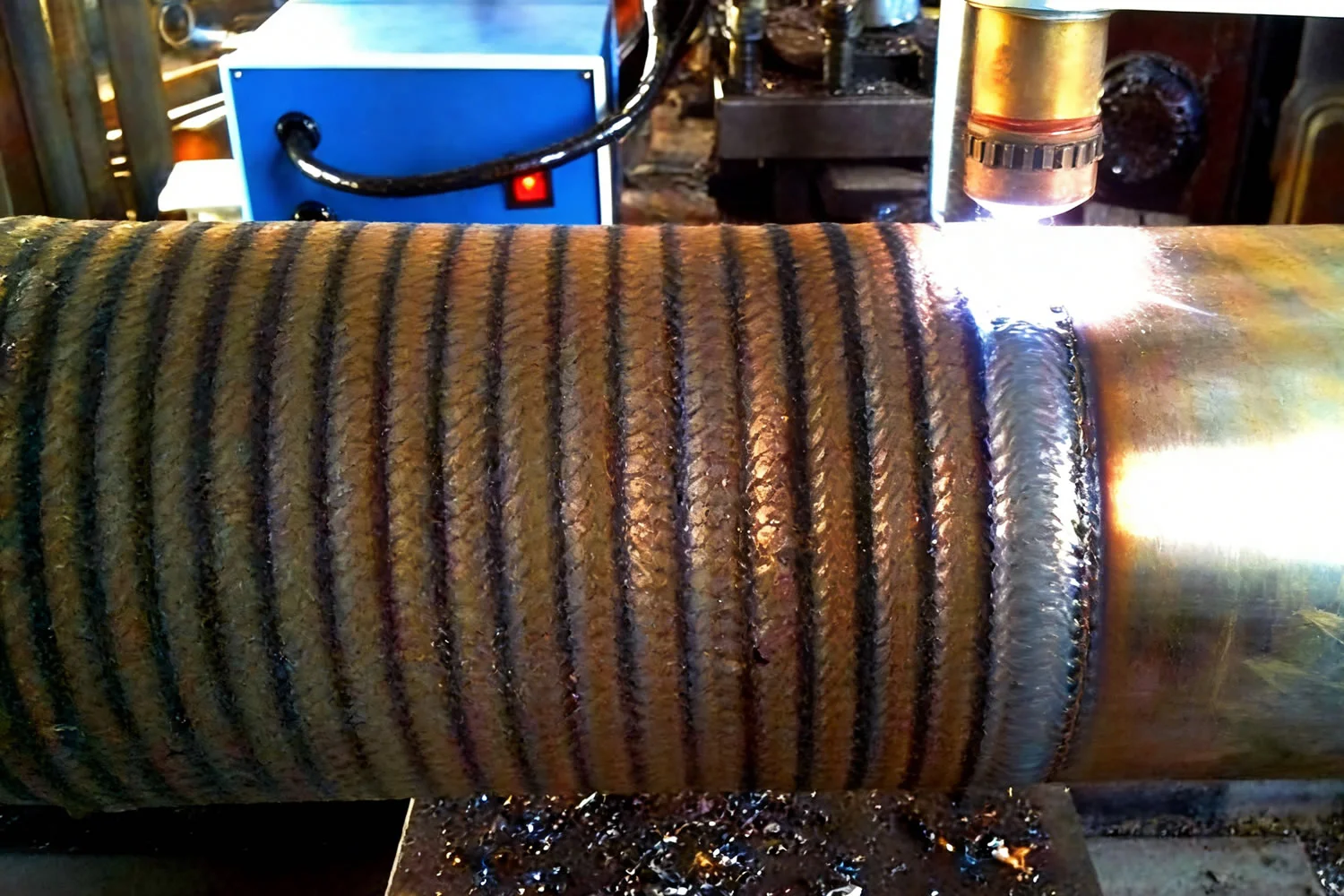

OD-Clad tubes deliver robust external hardfacing using advanced chromium and complex carbide consumables, achieving extreme abrasion resistance (>800 HV / 65 HRC) with even carbide distribution. Precision arc welding ensures minimal dilution and distortion—perfect for protecting outer surfaces in abrasive, corrosive, and high-impact environments across industrial piping systems.

OD-Clad tubes, also known as externally hardfaced tubes or external clad tubes, provide exceptional outer surface protection through arc welding with chromium and complex carbide cored wires. The tough matrix with finely dispersed carbides delivers hardness exceeding 800 HV (65 HRC), offering outstanding resistance to external abrasion, impact, corrosion, and high temperatures up to 1500°C. Manufactured with overlapping radial welds for uniform coverage and minimal preferential wear, these abrasion resistant OD tubes feature lightweight construction, customizable dimensions (diameters from 50mm, lengths up to 3000mm, cladding thickness 3mm+), and seamless integration options. Compared to unprotected pipes, OD-Clad externally clad tubes significantly extend service life, reduce maintenance and replacement frequency, minimize spillage/wastage, improve uptime, and lower total cost of ownership in demanding environments.

Hardfacing significantly improves resistance to abrasion and surface wear, extending the service life of metal components by up to 300%.

Ideal for mining, agriculture, and remote operations, hardfacing keeps equipment running while replacement parts are being manufactured or shipped.

By minimizing part replacement and reducing spare inventory, hardfacing can cut total replacement costs by 25%–75% over time.

| Internal Ø (mm) | Wall Thickness (mm) | Wear Layer (mm) | Available Lengths (mm) |

|---|---|---|---|

| 46.3 | 4-5.6 | 3 | 1000-2000 |

| 55.8-200.4 | 4.5-7.1 | 3 (standard) | Up to 3000 |

| Min Diameter | Approx. 50mm | ||

| Hardness | >800 HV (65 HRC) | ||

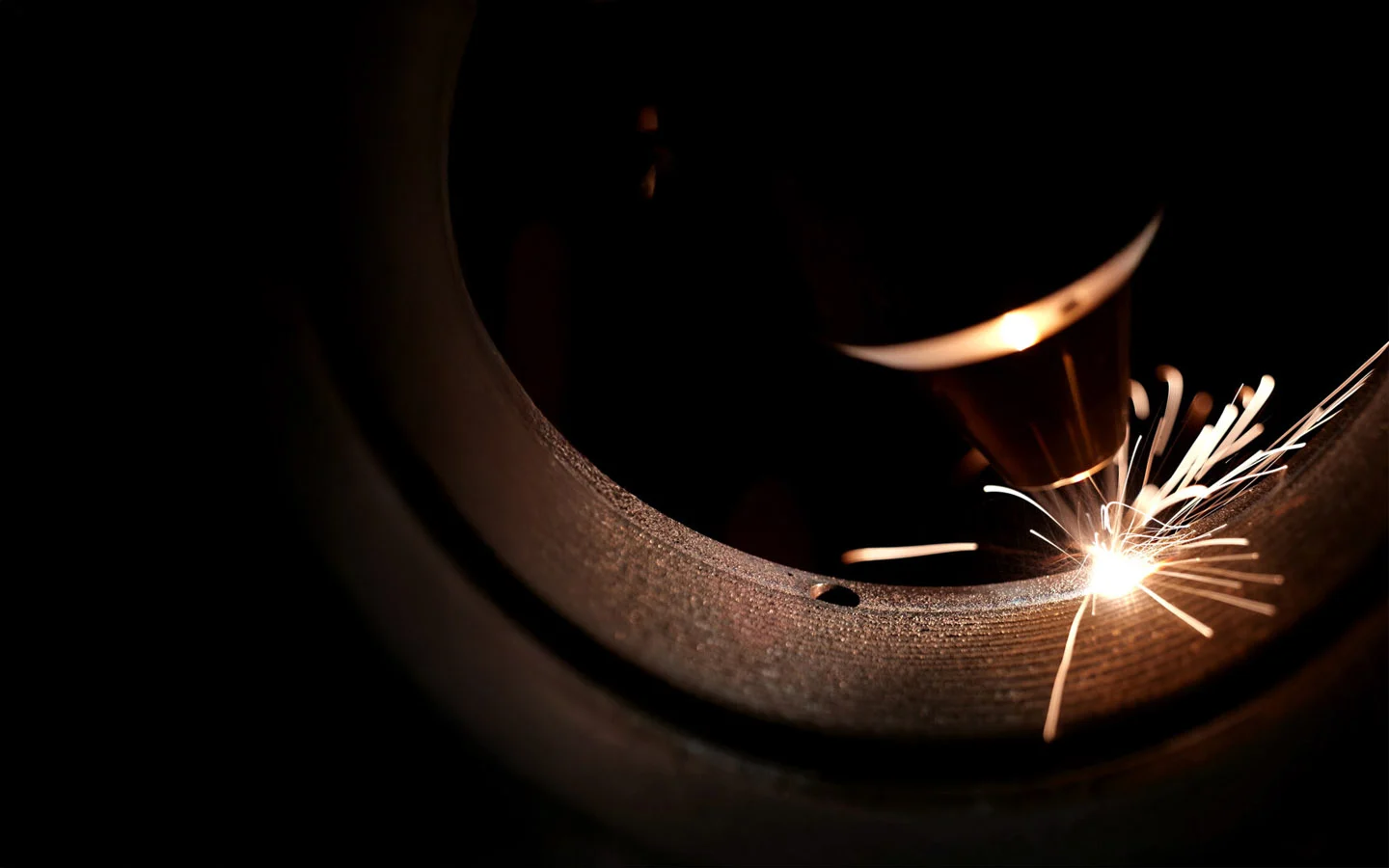

ID-Clad tubes, known as internally hardfaced tubes or carbide clad tubes, provide unmatched protection against abrasive wear through advanced internal hardfacing with special carbide-containing cored wires. The customized alloy matrix with finely dispersed carbides achieves hardness exceeding 800 HV (65 HRC), offering superior resistance to erosion from high-velocity particles. Manufactured via precision radial internal welding for uniform cladding (3-5mm thick) and minimal shrinkage, these abrasion resistant clad tubes maintain perfect geometry even in diameters from 50mm upward and lengths up to 3000mm. Lightweight yet robust, with strong metallurgical bonding on unalloyed or alloyed base materials, ID-Clad internally clad tubes dramatically extend service life, reduce replacement frequency, simplify assembly with compatible consumables, and lower total costs in severe wear environments. Long-tail advantages include tailored alloy selection for specific media/temperatures, excellent performance in ASTM G65 wear tests, and reliable operation with loose/fixed flange connections.

HARD FACING

Hardfacing is widely used in applications where components are exposed to continuous impact, abrasion, or erosion. By reinforcing the working surface, it helps equipment maintain strength, dimensions, and performance over extended service periods.

Hardfacing Welding Consumables

Sort:0

Hardfaced Chutes, Hoppers & Liner Systems

Sort:0