High-performance Chromium-molybdenum Pipe Designed For Elevated Temperature And Pressure Service In Power And Petrochemical Plants.

Astm a335 p91 alloy pipes offer superior creep resistance, thermal strength, and oxidation protection, making them ideal for boilers and high-temperature systems.

ASTM A335 P91 Pipe is a premium-grade seamless ferritic alloy steel pipe designed for high-temperature and high-pressure applications, offering exceptional corrosion resistance and boiler pipeline protection. Conforming to the ASTM A335/ASME SA335 specification, this Chrome Moly Pipe is crafted from a 9% chromium and 1% molybdenum alloy, enhanced with vanadium, niobium, and nitrogen, making it a creep strength enhanced ferritic (CSEF) steel. It is widely used in power generation, petrochemical plants, refineries, and other industrial piping systems where durability and resistance to extreme conditions are critical.

The ASTM A335 P91 Pipe is manufactured through a seamless process, either hot-rolled or cold-drawn, and undergoes specific heat treatment: normalizing at 1050°C followed by air cooling to 200°C, and tempering at 760°C. This process ensures a martensitic microstructure, providing superior high-temperature strength (up to 650°C), creep resistance, and oxidation resistance. The alloy’s composition, with 8.0-9.5% chromium, 0.85-1.05% molybdenum, and trace amounts of vanadium (0.18-0.25%), niobium (0.06-0.10%), and nitrogen (0.03-0.07%), enhances its mechanical properties, making it ideal for boiler pipeline protection in subcritical and supercritical boiler systems.

The Seamless Alloy Pipes are designed for bending, flanging, and fusion welding, with careful attention to welding procedures to prevent issues like cold cracking or embrittlement. Preheating (200°C for thick-walled pipes) and post-weld heat treatment (750°C for at least 1 hour) are recommended to optimize weld integrity. The pipes are available in sizes from 1/2” to 24” (DN15 to DN600), with wall thicknesses ranging from SCH 40 to SCH XXS, and lengths up to 12 meters or customized. Surface treatments like varnishing, 3LPE, or FBE coatings further enhance corrosion resistance, while plain or beveled ends facilitate easy installation.

In applications involving abrasive materials or corrosive environments, such as ash handling in power plants or hydrocarbon processing in refineries, the ASTM A335 P91 Pipe outperforms traditional materials like P22 or T22, offering up to 10 times higher thermal fatigue life and reduced wall thickness requirements. Its high tensile strength (minimum 585 MPa) and yield strength (minimum 415 MPa) ensure reliability under extreme conditions, while its ability to resist hydrogen sulfide corrosion and stress cracking makes it suitable for oil and gas applications.

The ASTM A335 P91 Pipe addresses critical challenges like pipeline wear, corrosion, and thermal stress in high-throughput industrial systems. Its advanced alloy composition and seamless construction make it a reliable choice for engineers seeking durable industrial piping solutions for extreme environments. For applications requiring high-pressure boiler pipes or corrosion-resistant piping, this Chrome Moly Pipe delivers unmatched performance, safety, and longevity.

| Grade | Composition, % | Others | ||||||

|---|---|---|---|---|---|---|---|---|

| Carbon | Manganese | Phosphorus | Sulfur | Silicon | Chromium | Molybdenum | ||

| P91 Type 1 | 0.08 – 0.12 | 0.30 – 0.60 | 0.020, max | 0.010, max | 0.20 – 0.50 | 8.00 – 9.50 | 0.85 – 1.05 |

V: 0.18 – 0.25 N: 0.030 – 0.070 Ni: 0.40 max Al: 0.02 max Nb: 0.06 – 0.10 Ti: 0.01 max Zr: 0.01 max |

| P91 Type 2 (Heat Analysis) |

0.08 – 0.12 | 0.30 – 0.50 | 0.020, max | 0.005, max | 0.20 – 0.40 | 8.00 – 9.50 | 0.85 – 1.05 |

V: 0.18 – 0.25 Ni: 0.20 max Al: 0.020 max N: 0.035 – 0.070 N/Al ratio ≥ 4.0 Nb: 0.06 – 0.10 Ti: 0.01 max Zr: 0.01 max Sn: 0.010 max Sb: 0.003 max As: 0.010 max B: 0.001 max W: 0.05 max Cu: 0.10 max |

| P91 Type 2 (Product Analysis) |

0.07 – 0.13 | 0.30 – 0.50 | 0.020, max | 0.005, max | 0.20 – 0.40 | 8.00 – 9.50 | 0.80 – 1.05 |

V: 0.16 – 0.27 Ni: 0.20 max Al: 0.020 max N: 0.035 – 0.070 N/Al ratio ≥ 4.0 Nb: 0.05 – 0.11 Ti: 0.01 max Zr: 0.01 max Sn: 0.010 max Sb: 0.003 max As: 0.010 max B: 0.001 max W: 0.05 max Cu: 0.10 max |

|

Note: Compared with P91 Type 1, P91 Type 2 has more stringent chemical composition requirements and shows better corrosion and creep resistance under high temperatures and pressure. |

||||||||

| Property | Requirement | |

|---|---|---|

| Longitudinal | Transverse | |

| Grade | ASTM A335 P91 Type 1 and Type 2 | |

| Tensile strength, min | 85 [585] MPa | |

| Yield strength, min | 60 [415] MPa | |

| Elongation in 2 in. or 50 mm, min (%) | 20% | 13% |

| Basic minimum elongation for wall 5/16 in [8 mm] and over in thickness, strip tests, and for all small sizes tested in full section | 20% | - |

| When standard round 2 in or 50 mm gage length or proportionally smaller size specimen with the gage length equal to 4D (4 times the diameter) is used | 20% | 13% |

| For strip tests a deduction for each 1/32 in [0.8 mm] decrease in wall thickness below in. [8 mm] from the basic minimum elongation of the following percentage points shall be made | 1.00 | - |

| Grade | Brinell | Vickers | Rockwell |

|---|---|---|---|

| P91 Type 1 and Type 2 | 190 – 250 HBW | 196 – 265 HV | 91HRBW – 25 HRC |

| Grade | Heat Treat Type | Normalizing Temperature, min or range ℉ [℃] |

Cooling Media | Subcritical Annealing or Tempering Temperature, min or range ℉ [℃] |

|---|---|---|---|---|

| P91 Type 1, P91 Type 2 | normalize and temper | 1650 [900] | — | 1100 [595] |

| normalize and temper | 1900 – 1975 [1040 – 1080] | — | 1350 – 1470 [730 – 800] C | |

| quench and temper | 1900 – 1975 [1040 – 1080] | — | 1350 – 1470 [730 – 800] |

| Element | Composition (%) |

|---|---|

| Carbon (C) | 0.08–0.12 |

| Manganese (Mn) | 0.30–0.60 |

| Phosphorus (P) | ≤0.02 |

| Sulfur (S) | ≤0.01 |

| Silicon (Si) | 0.20–0.50 |

| Chromium (Cr) | 8.00–9.50 |

| Molybdenum (Mo) | 0.85–1.05 |

| Vanadium (V) | 0.18–0.25 |

| Niobium (Nb) | 0.06–0.10 |

| Nitrogen (N) | 0.03–0.07 |

| Property | Value |

|---|---|

| Tensile Strength (MPa) | 585 min |

| Yield Strength (MPa) | 415 min |

| Elongation (%) | 20 min |

| Hardness (HBW) | ≤250 |

| Grade | UNS Designation | Chemical Composition % | |||||||

|---|---|---|---|---|---|---|---|---|---|

| P91 Type 1 | K91560 | C | Mn | P | S | Si | Ni | Cr | Mo |

| 0.08-0.12 | 0.30-0.60 | 0.020 | 0.010 | 0.20-0.50 | 0.40 max | 8.00-9.50 | 0.85-1.05 | ||

| V | N | Al | Cb | Ti | Zr | Sn | Sb | ||

| 0.18-0.25 | 0.030-0.070 | 0.02 max | 0.06-010 | 0.01 max | 0.01 max | _ | _ | ||

| P91 Type 2 | K91560 | C | Mn | P | S | Si | Ni | Cr | Mo |

| 0.08-0.12 | 0.30-0.50 | 0.020 | 0.005 | 0.20-0.40 | 0.40 max | 8.00-9.50 | 0.85-1.05 | ||

| V | N | Al | Cb | Ti | Zr | Sn | Sb | ||

| 0.18-0.25 | 0.035-0.070 | 0.02 max | 0.06-0.10 | 0.01 max | 0.01 max | 0.010 max | 0.003 max | ||

ASTM A335 P91 Type 1 & Type 2 have subtle differences mainly in elements Mn, S, Si, N, Sn and Sb content, and Type 2 has stricter requirements on element content than Type 1. P91 type 1 and 2 shall have a hardness within the range of 190 to 250 [HBW] or 196 to 265 [HV] or 91 HRBW to 25 HRC.

P91 (9Cr-1Mo-V-Nb) is a high-performance ferritic alloy steel designed for high-temperature service in power plants and petrochemical systems.

Maintains mechanical performance up to 600°C, allowing reduced wall thickness in steam piping and headers.

Withstands aggressive thermal and chemical environments, supporting advanced boiler design.

Offers up to 10× longer fatigue life compared to conventional steels, reducing shutdowns and failures.

Requires controlled heat treatment to maintain tempered martensitic structure and creep strength.

Chromium, molybdenum, vanadium, and niobium enhance strength, oxidation resistance, and weldability.

Widely used in superheaters, reheaters, HRSGs, and headers with compatible welding consumables.

P91 alloy steel has become the industry standard for high-efficiency power plant systems. It delivers exceptional performance in demanding thermal environments and is essential for systems operating under high pressure and temperature conditions.

ASTM A335 chrome moly pipes are widely used in various industries due to their excellent mechanical properties and resistance to high temperatures.

Used in high-temperature and high-pressure boiler tubes, superheaters, and reheaters for efficient energy conversion.

Applied in refineries and petrochemical plants to transport high-temperature hydrocarbons.

Used in facilities handling corrosive and high-temperature fluids during various chemical reactions.

Employed in nuclear power plants for critical piping systems resistant to extreme heat and pressure.

Used in furnaces and heat exchangers due to excellent resistance to high temperature and thermal fatigue.

Applied in high-pressure steam systems in industries like pulp and paper where thermal durability is essential.

Astm a335 p5 alloy steel pipe provides excellent h...

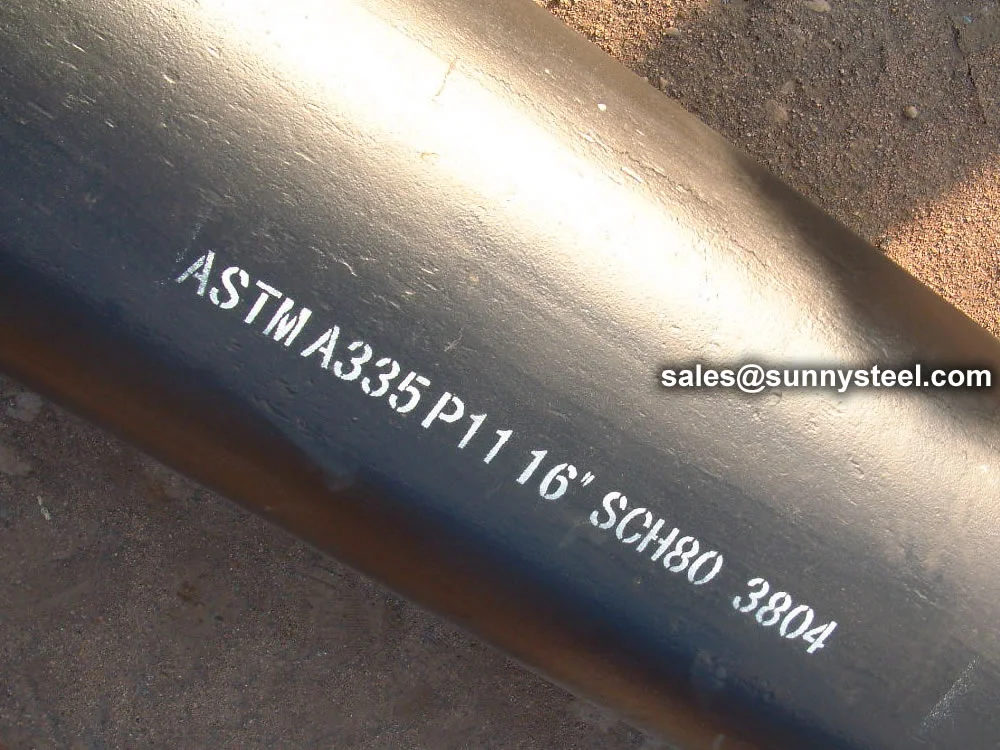

Astm a335 p11 alloy steel pipe provides reliable h...

Astm a335 p92 high pressure boiler pipe delivers e...

Astm a335 p22 pipe offers excellent corrosion resi...