Seamless Cold-drawn Low-carbon Steel Tubes For Condensers And Boilers

Astm a179 seamless cold-drawn tubes offer tight tolerances, excellent dimensional accuracy, and strong mechanical performance for heat exchanger and condenser applications.

Seamless Cold-drawn Low-carbon Steel Tubes For Condensers And Boilers

Astm a179 seamless cold-drawn tubes offer tight tolerances, excellent dimensional accuracy, and strong mechanical performance for heat exchanger and condenser applications.

ASTM A179 Tubes are seamless, cold-drawn, low-carbon steel tubes engineered for superior performance in heat exchanger and condenser applications. Conforming to ASTM A179/ASME SA179 standards, these tubes provide excellent corrosion resistance and thermal conductivity, making them ideal for boiler pipeline protection in industries such as power generation, petrochemical, and chemical processing. Their seamless construction ensures durability and reliability under high-pressure and high-temperature conditions.

The ASTM A179 Tubes are manufactured through a cold-drawing process, followed by heat treatment at 1200°F (650°C) or higher to optimize mechanical properties and surface finish. Available in outside diameters from 1/8” to 3” (3.2 mm to 76.2 mm) and wall thicknesses from 0.015” to 0.315” (0.4 mm to 8 mm), these tubes meet diverse project specifications. They undergo stringent testing, including flattening, flaring, hardness, and hydrostatic tests, ensuring compliance with ASTM A450/A450M standards. The low-carbon composition (0.06-0.18% carbon) enhances weldability and minimizes corrosion, making them perfect for seamless heat exchanger tubes.

These low carbon steel tubes excel in tubular heat exchangers, condensers, and similar heat transfer equipment due to their high thermal conductivity and abrasion resistance. Their ability to resist pipeline wear and corrosion makes them a top choice for power plants, refineries, and HVAC systems. Surface treatments like oil-dip, varnish, or passivation, along with U-bending options, support complex heat exchanger designs. The tubes are packed in wooden boxes or bundles with plastic paper for secure, sea-worthy delivery, ensuring they arrive in pristine condition.

The ASTM A179 Tubes address critical challenges like thermal stress, corrosion, and pipeline wear in industrial piping systems. Their cost-effective design and seamless construction make them a reliable choice for engineers seeking durable condenser tubes for extreme environments. Whether used in boiler systems or chemical processing, these tubes deliver unmatched heat transfer efficiency, safety, and longevity.

| OD(mm) | Wall Thickness Unit(mm) | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 2 | 2.5 | 3 | 3.5 | 4 | 4.5 | 5 | 6 | 6.5 - 7 | 7.5 - 8 | 8.5 - 9 | 9.5 - 10 | 11 | 12 | |

| Φ25-Φ28 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ32 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ34-Φ36 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ38 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ40 | ● | ● | ● | ● | ● | |||||||||

| Φ42 | ● | ● | ● | ● | ● | |||||||||

| Φ45 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ48-Φ60 | ● | ● | ● | ● | ● | ● | ● | |||||||

| Φ63.5 | ● | ● | ● | ● | ● | ● | ● | |||||||

| Φ68-Φ73 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ76 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ80 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ83 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ89 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ95 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ102 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ108 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ114 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||

| Φ121 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||

| Φ127 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||

| Φ133 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||

| Φ140 | ● | ● | ● | ● | ● | ● | ● | ● | ||||||

| Φ146 | ● | ● | ● | ● | ● | ● | ● | ● | ||||||

| Φ152 | ● | ● | ● | ● | ● | ● | ● | ● | ||||||

| Φ159 | ● | ● | ● | ● | ● | ● | ● | ● | ||||||

| Φ168 | ● | ● | ● | ● | ● | ● | ● | ● | ||||||

| Feature | ASTM A179 | ASTM A192 | ASTM A210 Grade A1 |

|---|---|---|---|

| Material Type | Low-Carbon Steel | Carbon Steel | Medium-Carbon Steel |

| Temperature Range | Moderate (Ambient to 400°C) | High (Up to 650°C) | High (Up to 600°C) |

| Corrosion Resistance | Good (Low-Carbon) | Moderate | Moderate |

| Applications | Heat Exchangers, Condensers | High-Pressure Boilers | Boilers, Superheaters |

| Tensile Strength (MPa) | 325 (min) | 325 (min) | 415 (min) |

| Yield Strength (MPa) | 180 (min) | 180 (min) | 255 (min) |

| Key Advantage | High thermal conductivity | High-pressure resistance | High strength for boilers |

Enhances heat transfer efficiency in condensers and heat exchangers.

Low-carbon steel resists corrosion in harsh environments.

Durable construction withstands pipeline wear and tear.

Cold-drawn process ensures uniform strength and reliability.

Supports U-bending and welding for versatile applications.

Low-carbon steel reduces costs without sacrificing quality.

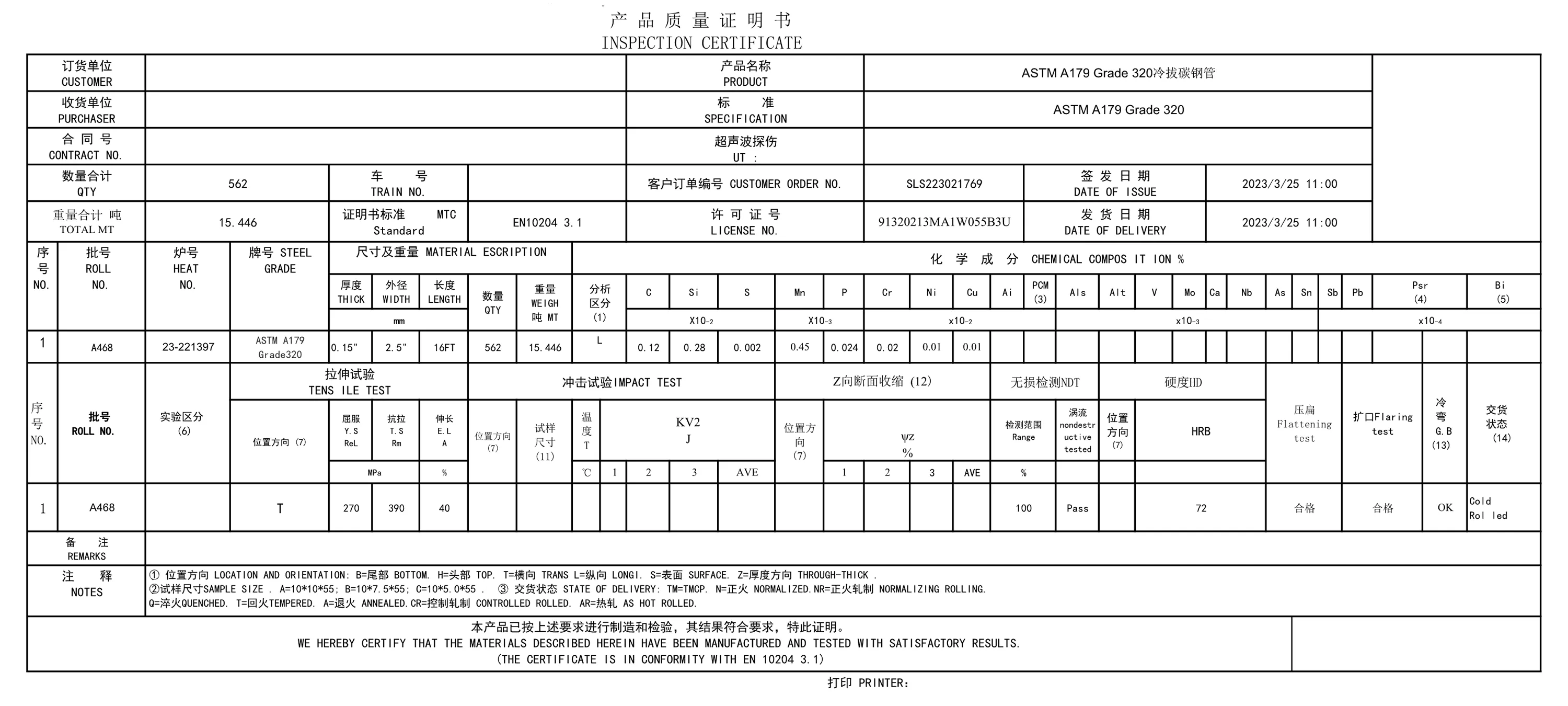

ASTM A179 and ASME SA179 specify seamless cold-drawn low-carbon steel tubes for heat exchangers and condensers, while ASME SA450 provides general requirements for carbon and low-alloy steel tubes. Below are the chemical composition, mechanical properties, and dimensional tolerances for these tubes.

| Element | Percentage |

|---|---|

| Carbon (C) | 0.06–0.18% |

| Manganese (Mn) | 0.27–0.63% |

| Phosphorus (P) | ≤0.035% |

| Sulfur (S) | ≤0.035% |

| Silicon (Si) | ≤0.25% (if applicable, per agreement) |

| Property | Value |

|---|---|

| Tensile Strength | ≥325 MPa (47 ksi) |

| Yield Strength | ≥180 MPa (26 ksi) |

| Elongation | ≥35% (in 2 inches) |

| Hardness | ≤72 HRB (Rockwell B) |

| Parameter | Tolerance |

|---|---|

| Outside Diameter (OD) | ±0.10 mm for OD ≤ 38.1 mm; ±0.20 mm for OD > 38.1 mm |

| Wall Thickness | ±10% of nominal wall thickness |

| Length | ±6 mm for cut lengths; per agreement for specific lengths |

| Straightness | ≤1.5 mm/m deviation |

| Element | Composition (%) |

|---|---|

| Carbon (C) | 0.06-0.18 |

| Manganese (Mn) | 0.27-0.63 |

| Phosphorus (P) | ≤0.035 |

| Sulfur (S) | ≤0.035 |

| Property | Value |

|---|---|

| Tensile Strength, min (MPa) | 325 |

| Yield Strength, min (MPa) | 180 |

| Elongation, min (%) | 35 |

| Hardness, max (HRB) | 72 |

ASTM A450 covers carbon and low alloy steel tube. Steel samples shall be melt processed and shall either be ingot cast or strand cast. Heat and product analyses shall be performed on the steel materials. Steel specimens shall also undergo tensile tests and shall conform to required values of yield strength and elongation. Flattening test, reverse flattening test, flaring test, flange test, hardness test, hydrostatic test, air underwater pressure test, and nondestructive tests shall be performed on the steel materials.

| OD (in / mm) | ≤0.095 in (2.4 mm) | 0.095–0.150 in (2.4–3.8 mm) | 0.150–0.180 in (3.8–4.6 mm) | >0.180 in (>4.6 mm) | ||||

|---|---|---|---|---|---|---|---|---|

| Seamless ± | Welded ± | Seamless ± | Welded ± | Seamless ± | Welded ± | Seamless ± | Welded ± | |

| ≤4 in (≤101.6 mm) | 40 / 0% | 18 / 0% | 35 / 0% | 18 / 0% | 33 / 0% | 18 / 0% | 28 / 0% | 18 / 0% |

| >4 in (>101.6 mm) | – | – | 35 / 0% | 18 / 0% | 33 / 0% | 18 / 0% | 28 / 0% | 18 / 0% |

| Tube Type | OD Range | + (in / mm) | – (in / mm) |

|---|---|---|---|

| Hot‑Finished Seamless | ≤4 in (≤101.6 mm) | +1⁄64″ (0.4 mm) | –1⁄32″ (0.8 mm) |

| >4–7½ in (101.6–190.5 mm) | +1⁄64″ (0.4 mm) | –3⁄64″ (1.2 mm) | |

| Welded & Cold‑Finished Seamless | ≤1 in (≤25.4 mm) | +0.004″ (0.1 mm) | –0.004″ (0.1 mm) |

| 1 – 1½ in (25.4–38.1 mm) | +0.006″ (0.15 mm) | –0.006″ (0.15 mm) | |

| 1½ – 2 in (38.1–50.8 mm) | +0.008″ (0.2 mm) | –0.008″ (0.2 mm) | |

| 2 – 2½ in (50.8–63.5 mm) | +0.010″ (0.25 mm) | –0.010″ (0.25 mm) | |

| 2½ – 3 in (63.5–76.2 mm) | +0.012″ (0.30 mm) | –0.012″ (0.30 mm) | |

| 3 – 4 in (76.2–101.6 mm) | +0.015″ (0.38 mm) | –0.015″ (0.38 mm) | |

| 4 – 7½ in (101.6–190.5 mm) | +0.015″ (0.38 mm) | –0.025″ (0.64 mm) | |

| 7½ – 9 in (190.5–228.6 mm) | +0.015″ (0.38 mm) | –0.045″ (1.14 mm) | |

ASTM A179 (ASME SA179) specifies seamless, cold-drawn low-carbon steel tubes for heat exchangers, condensers, boilers, and similar heat-transfer equipment, with outside diameters from 1/8″ to 3″ (3.2 – 76.2 mm).

ASTM A179/A179M seamless cold-drawn low-carbon steel tubes are widely used in high-pressure, heat transfer, and hygienic applications across diverse industries.

Used extensively in tubular heat exchangers, condensers, boilers, and similar equipment where efficient thermal transfer and pressure tolerance are required. :contentReference[oaicite:1]{index=1}

Applied in power plants—thermal and nuclear—for steam transfer systems, thanks to their high pressure and temperature resistance. :contentReference[oaicite:2]{index=2}

Used in petrochemical plants, gas processing, and specialty chemicals for safe transport of aggressive fluids under heat and pressure. :contentReference[oaicite:3]{index=3}

Employed in pharmaceutical equipment and food-grade condensers where hygienic standards and corrosion resistance are essential. :contentReference[oaicite:4]{index=4}

Suitable for seawater equipment and offshore drilling platforms due to its corrosion resistance and mechanical strength. :contentReference[oaicite:5]{index=5}

Used in heat transfer and processing equipment where reliability under pressure and temperature is critical. :contentReference[oaicite:6]{index=6}

Astm a53 steel pipe meets stringent technical requ...

Astm a209 tubes offer seamless alloy steel solutio...

ASTM A192 seamless boiler tubes deliver exceptiona...