Seamless Tubes For Hydraulic And Pneumatic Systems

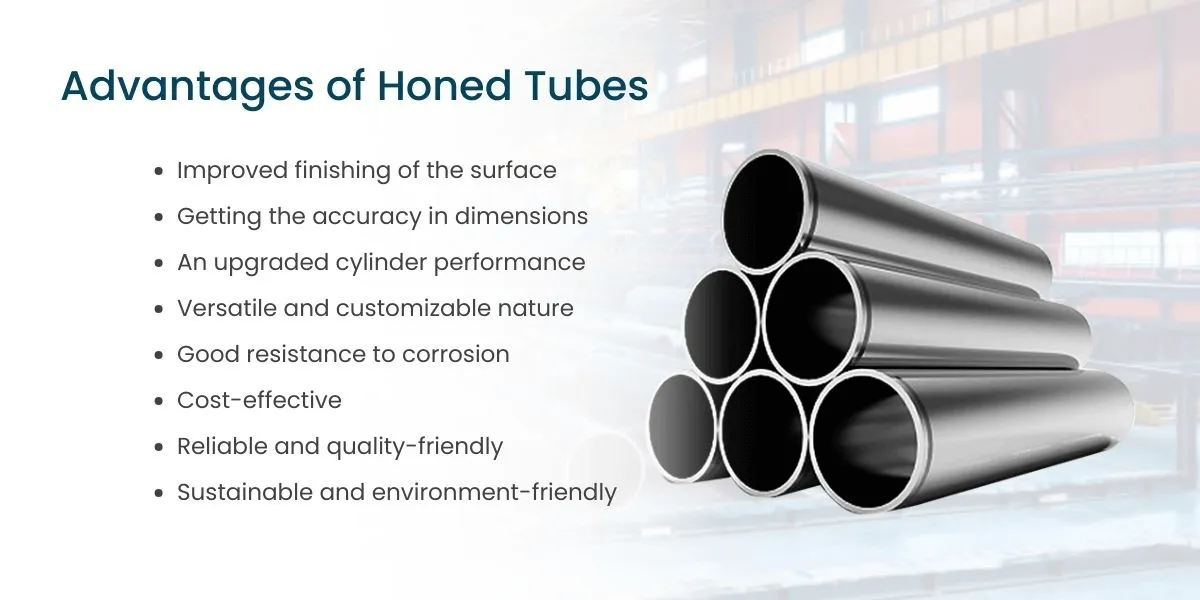

Honed tubes offer precision bore and corrosion resistance for hydraulic and pneumatic cylinders in industrial applications.

Honed Tubes are seamless, precision-engineered steel tubes with a smooth bore, designed for hydraulic cylinder tubes and pneumatic cylinder tubes. Conforming to standards like DIN 2391, EN 10305-1, and ASTM A519, these tubes offer exceptional corrosion resistance and durability, making them ideal for high-pressure applications in industries such as construction, automotive, and heavy machinery.

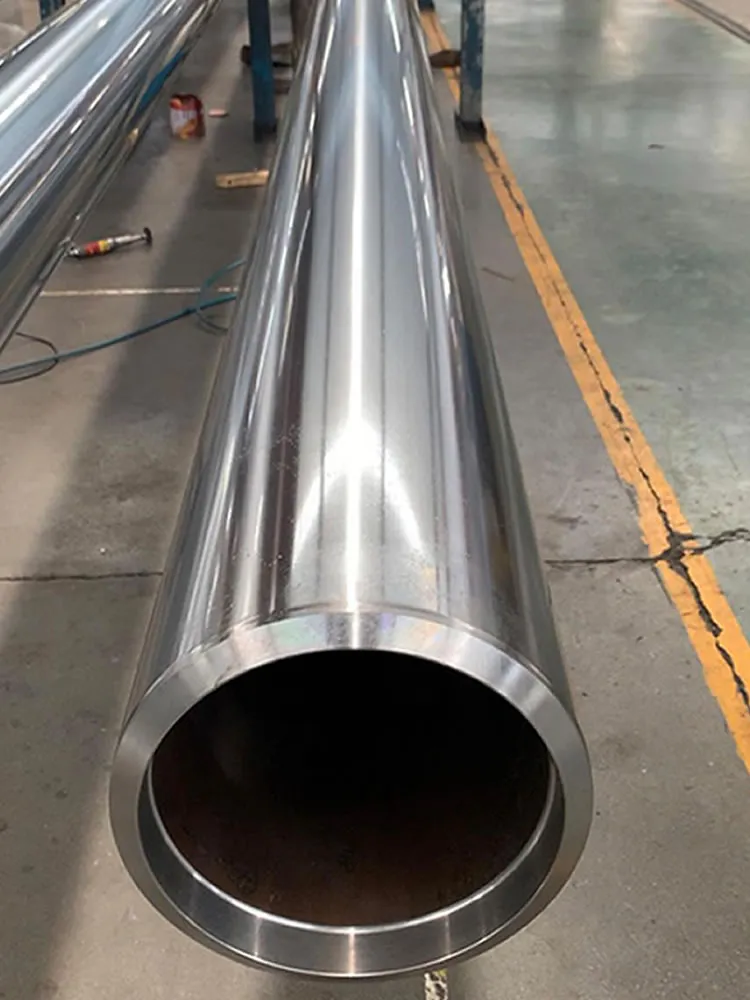

Manufactured through cold-drawing processes, Precision Honed Tubes achieve tight dimensional tolerances (H7–H9) and surface roughness (Ra ≤ 0.4 µm), ensuring optimal performance in hydraulic and pneumatic systems. Available in outer diameters from 30 mm to 500 mm and wall thicknesses from 3 mm to 50 mm, they can be supplied in lengths up to 12 meters. Materials like ST52, E355, or 1026 are heat-treated (e.g., stress-relieved or annealed) to enhance mechanical properties and resist pipeline wear.

The chemical composition typically includes carbon (0.10–0.22%), manganese (0.60–1.60%), phosphorus (≤0.025%), sulfur (≤0.015%), and silicon (0.15–0.35%), ensuring high strength and corrosion resistance. Rigorous testing, including dimensional checks, surface quality inspections, and hydrostatic tests, ensures compliance with industry standards. Surface treatments like phosphating or light oiling protect against corrosion, while the honed or skived and roller-burnished interior ensures minimal friction and extended seal life.

Honed Tubes are critical for hydraulic cylinders in excavators, cranes, and injection molding machines, as well as pneumatic cylinders in automation systems. Compared to standard tubes, honed tubes offer superior surface finish and precision, reducing wear on seals and pistons, and improving system efficiency. Their seamless construction and high-pressure resistance (up to 70 MPa) make them suitable for demanding applications where reliability is paramount.

These tubes address challenges like internal surface wear, corrosion, and pressure fluctuations in hydraulic systems. Their precision manufacturing, compliance with stringent standards, and robust material properties make Seamless Honed Tubes a preferred choice for engineers seeking durable solutions for high-performance hydraulic and pneumatic applications.

CDS

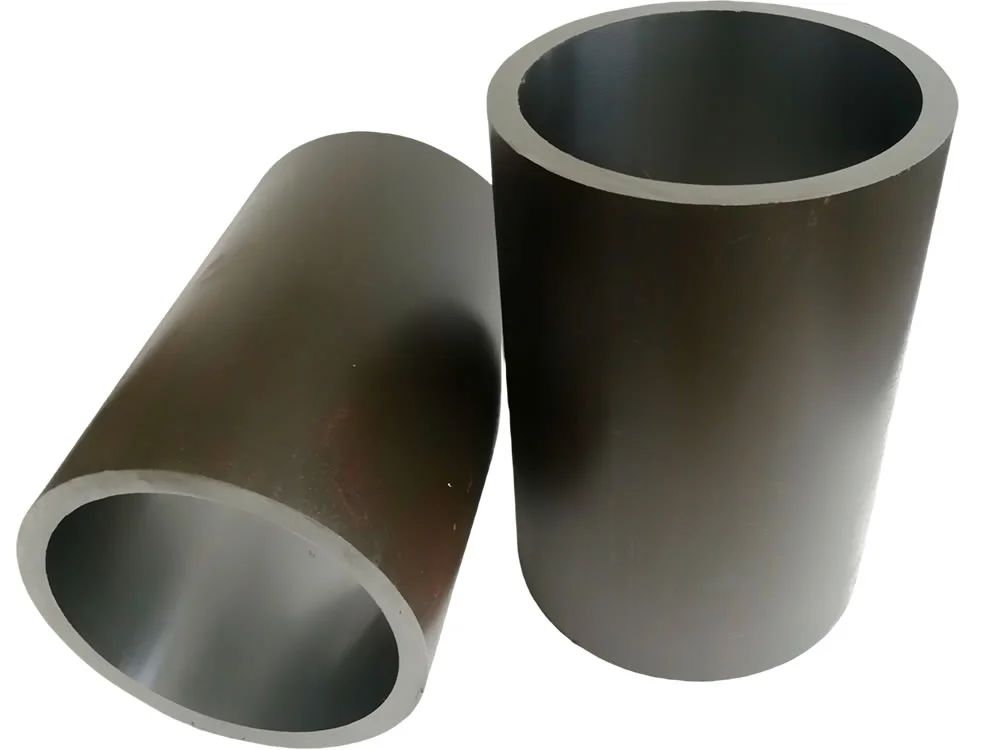

Honed tubes are precision‑engineered steel tubes with a smooth bore, designed primarily for hydraulic and pneumatic cylinder applications. They offer a precisely machined inner surface for high accuracy and surface finish in demanding industrial environments.

Also known as hydraulic cylinder tubes, honed tubes are widely used in hydraulic and pneumatic systems. Variants include cold‑drawn seamless tubes (“Suitable to Hone”) and DOM tubes.

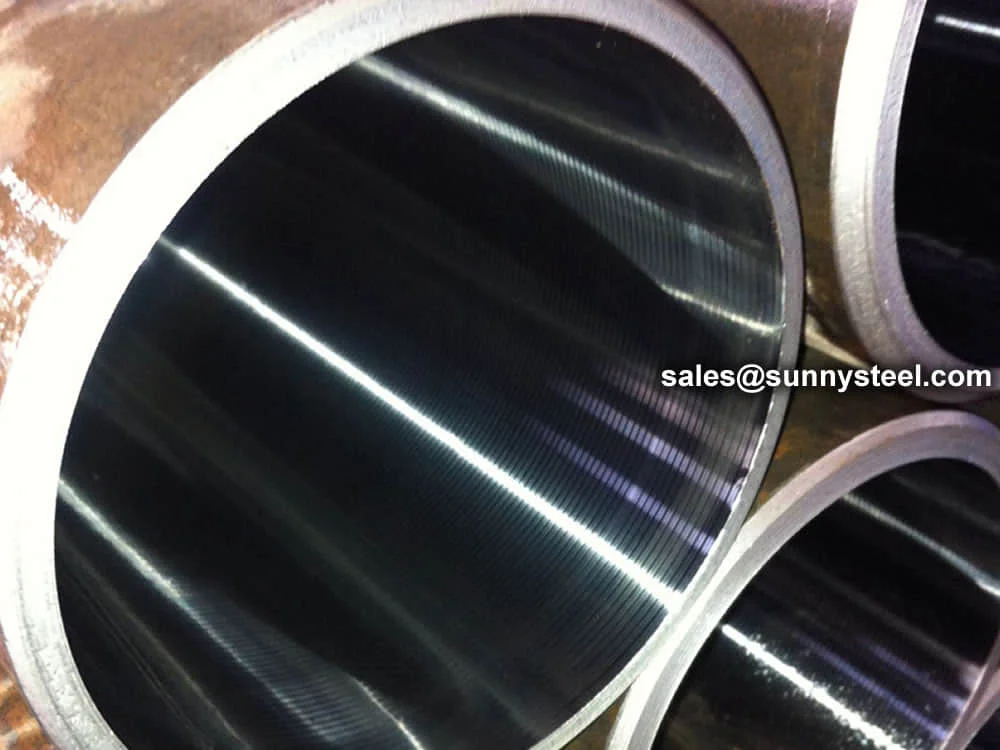

The inner bore is finished by either honing or skiving & roller burnishing. Honing delivers ultra‑smooth ID (Ra 0.1–0.2 µm), while skiving & burnishing is faster, achieves Ra ≈ 0.2–0.4 µm, and offers superb dimensional control and surface hardness.

Cylinder Tubes

Cylinder tubes, manufactured to precise tolerances, ensure reliable sealing and smooth operation in hydraulic and pneumatic systems, ideal for pistons and plungers in demanding industrial settings.

Cylinder tubes are critical for applications requiring reliable and efficient movement in hydraulic or pneumatic systems. Manufactured to precise tolerances, these tubes ensure optimal sealing and smooth operation in demanding industrial environments.

Generally, this pipe used for hydraulic equipment and institutional structure which has high precision and good surface finish, which including piston and plunger type

30 Mn2, 27SiMn, Q345, E355, E470, 20# etc

Dimensional precision: Cylinder pipe with few deviation in wall thickness tolerance, wall unevenness, outside tolerance and ovality

Surface Quality: Through the plug, mandrel and furnace temperature can control internal and external surface finish, control tube oxidation skin pits and others defect that can meet the requirements of clients

Size measurement

Honed tubes are manufactured to meet stringent technical specifications, ensuring high precision and performance across various industrial applications. Key specifications include:

The honing process uses abrasive polishing stones and paper to remove small amounts of material, producing extremely precise internal dimensions and improved finishes. Honed tubing is ready for hydraulic cylinder applications without further ID processing, making it an essential material for manufacturing high-performance cylinders.

H7–H9 tolerances and Ra ≤ 0.4 µm ensure smooth operation.

Phosphating or oiling protects against environmental degradation.

Withstands pressures up to 70 MPa in hydraulic systems.

Smooth bore reduces wear on seals and pistons.

Durable design reduces maintenance and downtime.

Available in various diameters and lengths up to 12 m.

| Grade | C (% max) | Si (% max) | Mn (%) | P (% max) | S (% max) |

|---|---|---|---|---|---|

| ST52 (DIN 2391) | 0.22 | 0.55 | 1.60 | 0.025 | 0.015 |

| E355 (EN 10305-1) | 0.22 | 0.55 | 1.60 | 0.025 | 0.015 |

| ASTM A519 1026 | 0.22–0.28 | 0.15–0.35 | 0.60–0.90 | 0.040 | 0.050 |

| Grade | Tensile Strength (MPa min) | Yield Strength (MPa min) | Elongation (% min) |

|---|---|---|---|

| ST52 (DIN 2391) | 600 | 520 | 14 |

| E355 (EN 10305-1) | 580 | 450 | 15 |

| ASTM A519 1026 | 515 | 350 | 15 |

| Feature | Honed Tubes | Standard Tubes |

|---|---|---|

| Material Type | Carbon/Alloy Steel (ST52, E355) | Carbon Steel |

| Surface Finish | Ra ≤0.4 µm (Honed/SR-B) | Ra ≥1.0 µm |

| Tolerance | H7–H9 | H11 or lower |

| Tensile Strength (MPa) | 515–600 | 400–500 |

| Applications | Hydraulic/Pneumatic Cylinders | General Piping |

| Cost | Higher (precision processing) | Lower |

| Key Advantage | Precision bore, extended seal life | Cost-effective for non-precision uses |

| ID (mm) | TOLERANCE (mm) | |||

|---|---|---|---|---|

| H7 | H8 | H9 | H10 | |

| ≦30 | +0.021/0 | +0.033/0 | +0.052/0 | +0.084/0 |

| 30 – ≦50 | +0.025/0 | +0.039/0 | +0.062/0 | +0.100/0 |

| 50 – ≦80 | +0.030/0 | +0.046/0 | +0.074/0 | +0.120/0 |

| 80 – ≦120 | +0.035/0 | +0.054/0 | +0.087/0 | +0.140/0 |

| 120 – ≦180 | +0.040/0 | +0.063/0 | +0.100/0 | +0.160/0 |

| 180 – ≦250 | +0.046/0 | +0.072/0 | +0.115/0 | +0.185/0 |

| 250 – ≦315 | +0.052/0 | +0.081/0 | +0.130/0 | +0.210/0 |

| 315 – ≦700 | +0.057/0 | +0.089/0 | +0.140/0 | +0.230/0 |

This will provide long piston seal life and prevent failure of the cylinder. The tube material is selected on the basis of application & working pressure.

The seamless tube for hydraulic cylinders, obtained from high quality cold drawn tubes, available in a wide dimensional range.

Select round bars of suitable size that meet the required standards as raw material bars for processing.

Process the steel round bar through free forging and heat treatment.

Use a forging hammer to straighten the treated raw material bar.

Produce seamless mother pipes from the round bars using hot rolling, hot extrusion, or hot piercing.

Cold draw the mother pipe to create cold-drawn seamless tubes (CDS tubes) and prepare pre-honed tubes.

The honing process, a form of grinding and a finishing method, enhances surface finish and wear resistance with high productivity and machining accuracy.

Apply NBK finish, phosphate-coating and normalizing the tubes for corrosion resistance, followed by oiling inside and outside.

Heat metals at a high temperature and allow them to cool naturally to room temperature, creating a tougher, more formable, harder, and ductile product.

Inspect the finished honed tubes according to customer requirements and standards, ensuring compliance with size, accuracy, mechanical properties, and chemical composition.

Explore honed tubes with targeted long-tail keywords, covering specifications, applications, and manufacturing for hydraulic and pneumatic systems.

Note: Honed tubes are precision-engineered for hydraulic and pneumatic systems, meeting DIN 2391, EN 10305-1, and ASTM A519 standards. Contact suppliers for detailed specifications.

The tube size e quality of steel required for the project were not standard, so it had been necessary not only to manufacture the tube on customer’s specification, starting from a specific raw material tube but also to plan a peculiar manufacturing process.

For example, also both left ends had been treated in order to let the assembly of the piece. It has to be stressed the importance of honing the left ends and the roundesses where the O-Ring is allocated since they impact dramatically on the system performance.

Honed tubes, characterized by their precisely machined inner surface, are essential components in various industrial applications where high accuracy and surface finish are crucial. They are used in hydraulic and pneumatic cylinders, offering precision and durability in construction, automotive, and industrial machinery applications.

They are a primary component in hydraulic cylinders, providing precise control and power in various applications.

Supports hydraulic systems in heavy vehicles and suspension systems.

Used in injection molding and press machines for precision operation.

Powers pneumatic cylinders in robotic and automated equipment.

Used in hydraulic systems for tractors and harvesters, providing precise control and power.

Supports hydraulic systems in marine equipment and vessels.

Why Honed Tubes? These tubes, made from high-quality seamless steel (e.g., ST52, E355), offer precision bore and corrosion resistance, ensuring reliable performance in high-pressure hydraulic and pneumatic systems.

Other structural pipes provide high strength and v...

Steel pipe for gas cylinder offers high-strength, ...

Seamless pipes for high-temperature applications o...