Tag#for abrasion resistant pipe Get: 61 results / Total 6 pages

Ni-hard wearback pipes combine the strength of mild steel with the exceptional wear resistance of ni-hard cast liners, making them ideal for mining, power, and cement industries facing severe abrasion.

Ceramic-lined pipes combine steel strength with hard ceramic interior to deliver long-lasting wear and corrosion protection—ideal for slurry, ash, and abrasive flows.

Ceramic tile lined pipes provide exceptional wear and corrosion resistance, making them ideal for transporting abrasive slurries and bulk materials.

Rare earth alloy wear resistant pipe delivers superior strength, hardness, and abrasion resistance, making it ideal for handling aggressive materials in mining, power, and metallurgical systems.

Silicon carbide ceramic-lined pipes offer ultra-high hardness, exceptional wear and corrosion resistance, and thermal stability—ideal for abrasive slurries, ash, and chemical pipelines.

Ceramic sleeve lined fittings provide durable abrasion and corrosion resistance, ensuring longer service life for elbows, tees, reducers, and special joints in aggressive flow systems.

The double-tube conveying system combines a wear-resistant inner pipe and a high-strength outer tube to deliver long-lasting, low-maintenance performance in harsh material handling environments.

Cast basalt pipes feature high mohs hardness and chemical resistance, delivering long-lasting protection in harsh industrial transport systems handling abrasive or corrosive materials.

Sunny steel enterprise ltd. – leading global supplier of abrasion-resistant pipes, fittings, and steel solutions. based in china, serving 100+ countries with cost-effective wear-resistant products for mining, power, and petrochemical industries. iso-certified quality and innovation since 2000.

Sunny steel enterprise ltd. – leading global supplier of abrasion-resistant pipes, fittings, and steel solutions. based in china, serving 100+ countries with cost-effective wear-resistant products for mining, power, and petrochemical industries. iso-certified quality and innovation since 2000.

Advanced bimetallic pipes combining carbon/low-alloy steel outer layer with high chromium alloy inner lining for exceptional abrasion, corrosion, and impact resistance. Manufactured via centrifugal casting for uniform, defect-free bonding. Lifespan 5-10 years in harsh slurries.

Ceramic tile lined wear resistant multi-pass pipe offers outstanding abrasion and corrosion resistance in multi-pass piping systems, ensuring reliable performance under harsh industrial conditions.

Bimetal clad pipe is cast with mold vanishing vacuum suction casting cladding process.

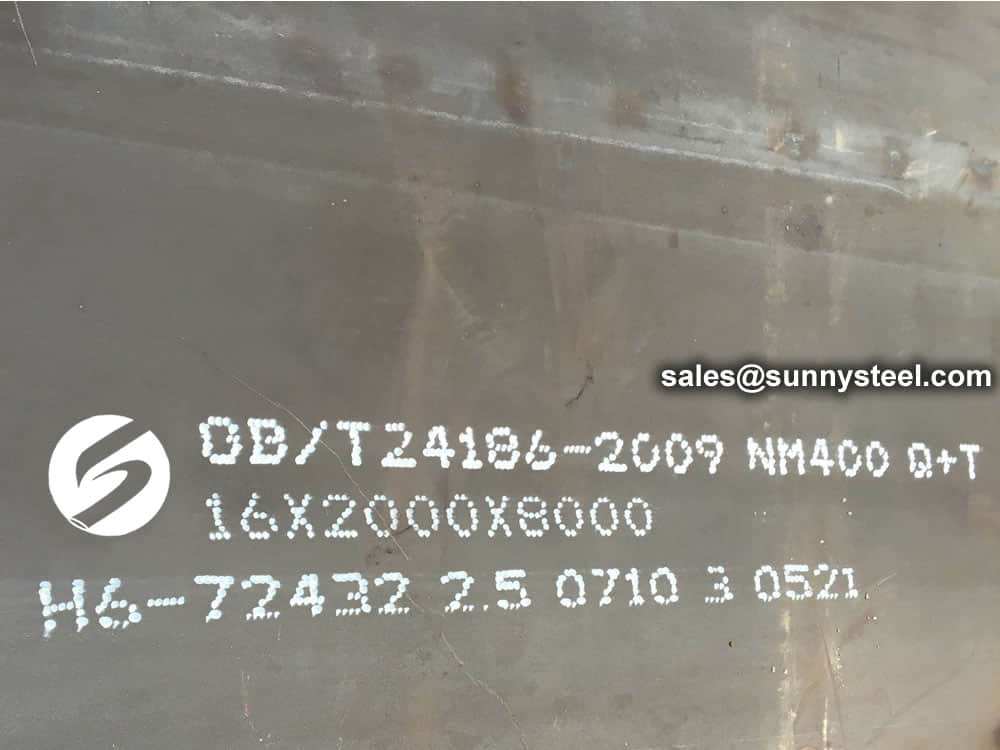

NM400 Steel Plate is a type of wear-resistant steel plate that is commonly used in various industrial applications.

Ceramic tile lined pipes are pipelines that have a ceramic tiles lining layer inside a steel pipe.

The wear resistance of the pulverized coal conveying pipeline of the boiler of the thermal power plant must be designed for leakproof, anti-corrosion, rain-proof, anti-freeze and other factors.