Weld-on Pipeline Erosion Protection

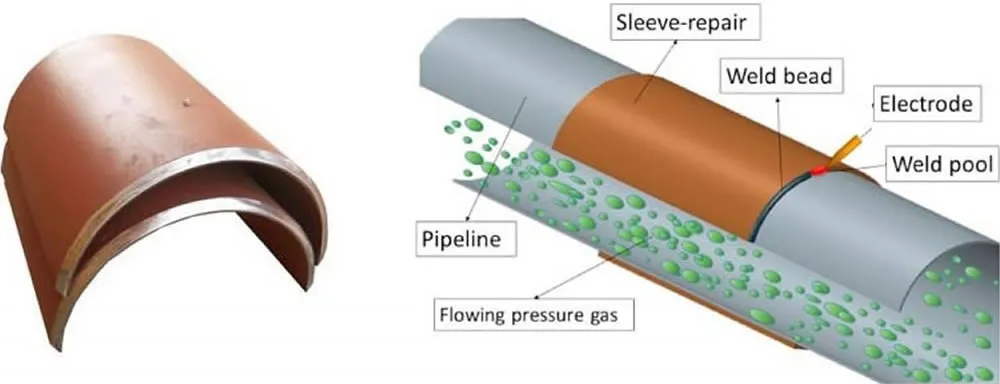

The half sleeves repair system offers permanent welded protection for damaged or thinning pipes, ideal for preventing corrosion and restoring strength in industrial piping.

Weld-on Pipeline Erosion Protection

The half sleeves repair system offers permanent welded protection for damaged or thinning pipes, ideal for preventing corrosion and restoring strength in industrial piping.

Half Repair Pipe Sleeves are designed to avoid costly downtime by allowing repairs on existing lines without shutting down production. We offer a full range of sizes, ASTM-grade steel, wall thickness options, and edge configurations. Also known as Split Casings or Half Wraps, they’re custom‑manufactured to ensure precision fit and secure reinforcement.

The half repair sleeve is a versatile solution used in pipeline maintenance to reinforce damaged sections and preserve line integrity.

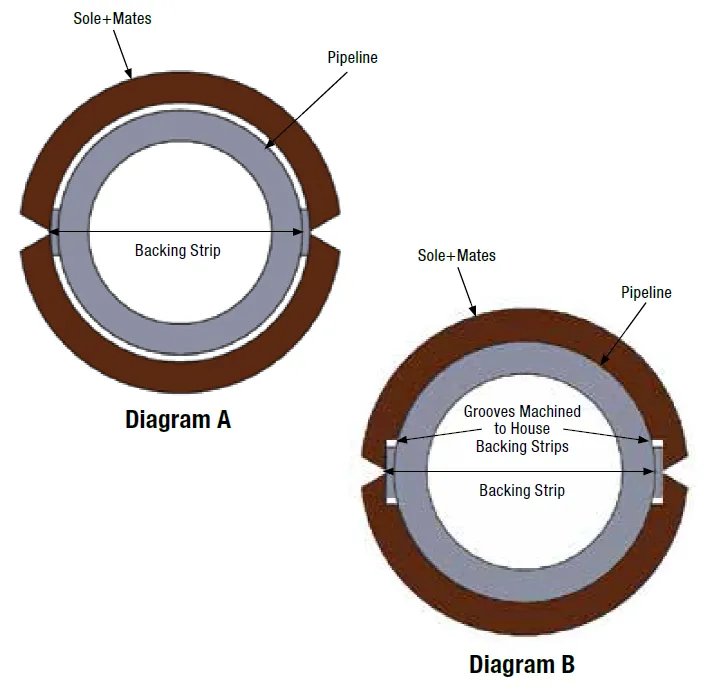

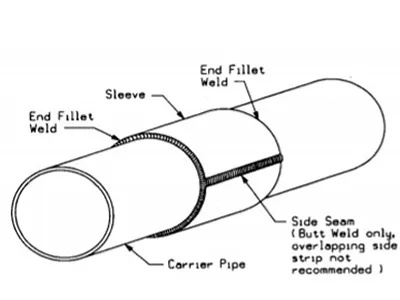

These pressure‑containing sleeves have wall thicknesses equal to or greater than required for maximum allowable operating pressure or the pipe’s full strength. Made from certified carbon steel (≤ 0.45%C), each sleeve comes with a pre-crimped backup strip. They function effectively as pads or cradles for above‑ground piping, support drains, or patch damaged sections—available in 90° or 180° segments ranging from 6″ to 10′ in length.

Steel repair sleeves address internal/external corrosion, gouges, dents, arc burns, cracks, defective welds, laminations, and leaks. Standard bevels, backup strips, square-cut ends, and certifications ensure reliable performance.

Suitable for leak repair, dents, corrosion, cracks, and faulty girth welds. Every sleeve features standard bevels with backup strips.

Constructed from structural-grade or pressure-vessel-grade carbon steel per ASTM/EN specs. Common grades include API 5L (Gr B, X42–X70), ASTM A36/A572/A516/A537, and EN S235–S450. Low carbon equivalent ensures weldability. Custom grades available on request.

Manufactured via rolling, die forming, and bending—never heat-treated. Standard square edges or optional bevels facilitate fillet welding. Edges milled for backup strips, with precise weld angles and depths to ensure strong joints.

Edges beveled to 30° (+5°/–0°) with 1/16″ root face. Inside diameter matches pipe OD, with 1/16″ edge gap for weld. Beveled or square ends per client spec.

Each sleeve is clearly marked with size, thickness, dimensions, and steel grade. Sleeves not meeting tolerance are rejected prior to domestic and export shipping.

Half pipe sleeves enable in-line repairs without shutting down the carrier line, ensuring uninterrupted throughput and operational continuity.

Comprehensive specifications for half pipe sleeves including materials, dimensions, and performance parameters for various industrial applications.

| Material Grade | Standard | Yield Strength | Tensile Strength | Applications |

|---|---|---|---|---|

| API 5L Grade B | API 5L PSL1/PSL2 | 245 MPa | 415 MPa | General pipeline applications |

| API 5L X42 | API 5L PSL1/PSL2 | 290 MPa | 415 MPa | Medium pressure pipelines |

| API 5L X52 | API 5L PSL1/PSL2 | 360 MPa | 460 MPa | High pressure transmission |

| ASTM A36 | ASTM A36 | 250 MPa | 400 MPa | Structural applications |

| ASTM A516 Gr.70 | ASTM A516 | 260 MPa | 485 MPa | Pressure vessel quality |

| ASTM A572 Gr.50 | ASTM A572 | 345 MPa | 450 MPa | High-strength low-alloy |

| Parameter | Range | Standard Options | Custom Options |

|---|---|---|---|

| Inside Diameter | 3.5″ – 64″ | 4", 6", 8", 10", 12", 16", 20", 24" | Any size per requirements |

| Length | 100mm – 3000mm | 1000mm, 1500mm, 2000mm | Custom lengths available |

| Wall Thickness | 5/16″ – 3/4″ | 3/8", 1/2", 5/8" | Based on pressure requirements |

| Coverage Angle | 185° per half | 370° total coverage | Complete circumferential |

| Edge Preparation | 30° bevel | Beveled for welding | Square-cut available |

-29°C to 400°C

(-20°F to 752°F)

ANSI 300–1500

Equal to carrier pipe

18–23% minimum

Superior ductility

Advanced manufacturing processes ensure consistent quality and optimal performance of half pipe sleeves for critical pipeline applications.

High-grade steel materials undergo chemical analysis (ASTM A751). Surface inspection and conditioning ensure optimal quality prior to forming.

Steel plates are cold-formed via precision rolling, die forming, or brake press to maintain dimensional accuracy and material integrity.

Longitudinal edges are beveled at 30° using precision machining to facilitate weldability and structural continuity in pipeline installation.

Inspections include tensile (ASTM A370), Charpy impact, bend testing, and dimensional/visual checks to meet strict project specifications.

Quality management system

B31.4, B31.8, PCC-2 compliance

API 5L, API 1104 certified

Comprehensive mechanical & chemical tests

Comprehensive advantages of implementing half pipe sleeves for pipeline maintenance and repair operations.

Install on pressurized, in-service pipelines without system shutdown, eliminating costly service interruptions and maintaining continuous operations.

Quick installation process completed in hours rather than days or weeks, minimizing operational disruption and reducing project timelines.

Significantly lower costs compared to pipeline replacement, including reduced material, labor, and operational expenses.

Restore full structural strength of original pipeline, allowing continued operation at design pressures and temperatures.

Accommodate pipeline movement, thermal expansion, and ground settlement without failure through superior material properties.

Minimal excavation reduces environmental impact, soil displacement, and habitat disruption compared to traditional replacement methods.

Repair various pipeline defects including corrosion, cracks, dents, manufacturing defects, and mechanical damage.

Significantly extend operational life of aging pipeline infrastructure, maximizing return on infrastructure investments.

Custom-fabricated designs for specific applications with tailored materials, dimensions, and performance characteristics.

API 5L Gr. B Half Repair Sleeve

Sort:0

Customized Alumina Ceramic Lined Project

Sort:99

High Chromium Alloy Lined Pipe

Sort:99

Sort:0

Wear-Resistant Hardfacing Liner Plate

Sort:0