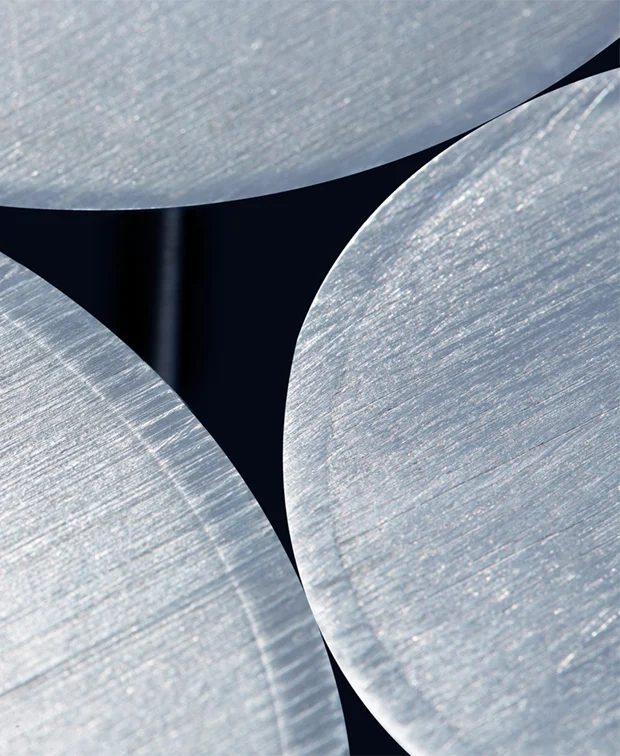

Hard Chrome Plated Steel Bars For Hydraulics

Hard chrome plated steel bars (induction hardened) for hydraulic pistons and rods.

Hard Chrome Plated Steel Bars For Hydraulics

Hard chrome plated steel bars (induction hardened) for hydraulic pistons and rods. 4140/42crmo4 material with 20-50 μm chrome layer. sizes od 12-250 mm, length up to 8m. superior wear resistance, low friction, and corrosion protection.

Chrome bars are round steel rods with a hard chrome plating on the surface, typically induction hardened to HRC 50-60. The chrome layer provides exceptional wear resistance, low coefficient of friction, and corrosion protection, while the core steel offers high tensile strength and toughness.

Commonly used as piston rods in hydraulic cylinders, linear guides, and rams where smooth, durable motion is critical. The plating thickness (20-50 μm) ensures long life under high loads and harsh conditions.

| Parameter | Specification |

|---|---|

| Base Material | 4140 / 42CrMo4 (EN 10083) |

| Hardening | Induction hardened to HRC 50-60 (core) |

| Chrome Thickness | 20-50 μm (standard; custom up to 100 μm) |

| Surface Hardness | HRC 58-65 |

| Plating Type | Hard chrome (electrolytic) |

| Property | Value |

|---|---|

| Tensile Strength | 850-1000 MPa |

| Yield Strength | 650-800 MPa |

| Elongation | ≥12% |

| Hardness (Core) | HRC 28-34 |

| Hardness (Surface) | HRC 58-65 |

| Parameter | Range |

|---|---|

| Outside Diameter (OD) | 12–250 mm |

| Length | Up to 8 m (custom) |

| Diameter Tolerance | h8 (ISO 286) |

| Straightness | ≤0.2 mm/m |

| Surface Roughness | Ra 0.2-0.4 μm |

| Type | Carbon Content | Common Grades | Key Properties | Typical Applications |

|---|---|---|---|---|

| Low Carbon / Mild Steel | ≤0.3% | A36, 1018, 1020, 1008 | Excellent weldability, ductility, machinability | Structural frames, brackets, general fabrication |

| Medium Carbon Steel | 0.3–0.6% | 1045, 4140, 4340 | Balanced strength & toughness | Shafts, gears, automotive parts |

| High Carbon / Tool Steel | >0.6% | D2, O1, A2 | High hardness, wear resistance | Cutting tools, dies, punches |

| Alloy Steel | Varies | 4130, 4140, 8620, 4340 | Enhanced strength, fatigue resistance | Aerospace, heavy machinery, oil & gas |

| Stainless Steel | Varies | 304, 316, 17-4PH | Corrosion resistance | Food processing, marine, medical |

| Rebar Grades | Varies | Grade 40, 60, 75 (ASTM) | Yield strength in ksi | Concrete reinforcement |

We has more than ten sets of circular saw machines and band saw machines, which can cut a large variety of steel materials (such as carbon steel, high carbon steel, alloy steel, tool steel, seamless steel tubes, free cutting steel, stainless steel, square bars, hexagonal bars, special shaped steel, steel plate, etc.).

| Item | mm | inch |

|---|---|---|

| Outer Dia. | 8~150 | 0.31~4.13 |

| Length Tolerance | 0~0.2 | 0~0.007 |

| Verticality Tolerance | 0~0.2 | 0~0.007 |

| Item | mm | inch |

|---|---|---|

| Outer Dia. | 8~600 | 0.31~23.62 |

| Length Tolerance | 0~1.0 | 0~0.039 |

| Verticality Tolerance | 0~1.0 | 0~0.039 |

Here are the most common types and shapes of steel bars (also known as merchant bars or reinforcing bars when deformed), based on standard industry classifications. Steel bars are solid (non-hollow) lengths of steel, typically produced by hot rolling, cold drawing, or forging.

Rebar for concrete, structural supports, beams, columns.

Shafts, axles, keys, fasteners, tooling.

Gears, crankshafts, suspension components.

Brackets, frames, shelving, gates, ornamental work.

Agricultural implements, transportation equipment, repairs.

Selecting the right wear material is critical for service life and operating cost. Below is a practical comparison of common wear-resistant materials.

| Commodity name | Main size | Standard | Main steel grade | Main application | Remark |

|---|---|---|---|---|---|

| High quality carbon steel | Ф14~Ф130 | GB/T 699-1999、JIS、ASTM、SAE、DIN Standard and technical agreement for users |

08~85、15Mn~70Mn、S10C~S58C、1006~1095CF53、C45, etc. | Machining, forge, automobile, motorcycle, agricultural machinery, mine and heavy-duty machinery, rolling stock, petrochemical industry, etc. |

20# forged steel is certified as the physical quality of products “Gold Award Certification” |

| Structural alloy steel | Ф14~Ф130 | GB/T 3077、JIS、ASTM、SAE、DIN and technical agreement for users |

Mn2.cr、SiMn、B、MnB、MnVB、CrMo、CrMoV、CrV、CrMn、CrMnSi、CrMnMo、CrMnAl、SC Series steel and various series of domestic and foreign structural alloy steel grade |

Structural pipe steel billet and machinery steel | |

| The hardenability of structural steel, pinion steel | Ф14~Ф130 | GB/T 5216-2004、ASTM A304、JIS G4052、SAE、DIN and technical agreement for users |

MnBH、MnTiBH、CrMoH、CrMnMoH、CrMnTiH、CrNiMoH、SCrH、SCMH、16MnCr5、20MnCr5 and various series of pinion steel grade | Automobile, motorcycle, agricultural machinery, mine and heavy-duty machinery, locomotive and rolling stock and various gears and gear axle steel |

|

| Spring steel | Ф14~Ф130 | GB/T 1222、ASTM A689、JIS G4801、DIN 17221 and technical agreement for users |

5~85、65Mn、SiMnVB、Si2Mn、Si2Cr、Si2CrV、SiCr、CrMn、CrV、CrMnB、Si2CrVAT、SUP3~SUP13(A)、38Si7、55Cr3、51CrV44 series of domestic and foreign spring steel grade | Automobile, motorcycle, agricultural machinery, mine and heavy-duty machinery, rolling stock, power system and various spring steel |

|

| Bearing steel | Ф14~Ф80 | GB/T 18254-2002、ASTM A295、JIS G4805、DIN 17230 and technical agreement for users |

GCr15、GCr15-Y、GCr15-G、GCr15SiMn、GCr15SiMo、SUJ2、100Cr6 series of domestic and foreign bearing steel grade | Automobile, motorcycle, agricultural machinery, mine and heavy-duty machinery, rolling stock and various machinery bearing steel |

|

| Carbon tool steel | Ф14~Ф130 | GB/T 1298-2008 and technical agreement for users |

T7~T13、T8Mn series of domestic and foreign carbon tool steel | Wood working tool, small tool, electrical, lathe tool, screw processing tool, stamping die, measuring tool, paper mould, cutter, etc. | |

| Alloy tool steel | Ф14~Ф120 | GB/T 1299-2000 and technical agreement for users |

9SiCr、8MnSi、5CrMnMo、5CrNiMo、3Cr2Mo、40MnMoV、LT-B2~LT-B6 series of domestic and foreign low alloy tool steel | Rock drill rod, cutter, cold working die, hot working die, plastic mould, cold stamping and hot extrusion mould, steel for impact resistance steel ball, etc. | |

| Pipe steel billet | Ф30~Ф130 | YB/T 5222-2004(2009)、YB/T 5221-1993、YB/T 5137-2007、GB/T 1591-2008、GB 13447-2008、JIS、ASTM、API and technical agreement for users | Excellent carbon and low alloy pipe steel billet: 08~85、15Mn~70Mn、Q345B、St30Al、A179, etc. | Make mechanical structure pipe, medium and low pressure pipe, high pressure pipe, oil well tube line pipe, automobile oil pipeline, automobile shaft-enclosing tube, oil drill collar tube, seamless cylinder, geological tube, etc. | API Q1, Certification 15CrMoG、Q345B is certified as the physical quality of products “Gold Award Certification”. |

| Alloy pipe steel billet: Mn2、Cr、SiMn、CrMo、CrMoV、CrMn、CrMnSi、34CrMo4、38Mn2V, etc. | |||||

| Oil well pipe steel billet: 25Mn2、28 Mn2、30 Mn2、37Mn5、33 MnB、42 MnMo7, etc. | |||||

| Pipe steel billet for high-pressure boiler: 20G、20MnG、25MnG、SA-106、SA-210A1、SA-210C、12Cr1MoVG、12Cr2MoG、15CrMoG、T11、T12、T22, etc. |

| Commodity name | Main size | Standard | Main steel grade | Main application |

|---|---|---|---|---|

| Chain steel, link steel | Ф14~Ф130 | GB/T 18669-2012 GB/T 549-2008 GB 10560-2008 JIS G 3105-2004 DIN 17115-2012 ASTM and technical agreement for users |

CM490(AM2), CM690(AM3), 20MnV, 25MnV, 23MnSiv, 23Mn2NiMoA, 25MnSiNiMoV, 25MnSiMoVA, 25MnSiNiMoA, 23MnNiCrMo54 and various series of domestic and foreign grade of link steel | Making lifting link, electric welded anchor cable, high tensile round link chain for mining, etc. |

| Weathering steel, corrosion resisting steel | Ф14~Ф130 | GB/T 4171-2008 and technical agreement for users | Q355GNH, SPA-H, 09CuPCrNiA, 10(HSC), 09CrCuSb, 09MnNiD etc. | Mainly making rolling stock, container, bridge, oil equipment, etc. |

| Easily cut steel | Ф14~Ф130 | GB/T 8731-2008 standards and technical agreement for users | Y12, Y15, Y40Mn, SAE1141, SAE1117, etc. | Automobile, construction machinery, etc. |

| Hot rolled high strength steel | Ф14~Ф130 | GB/T 15712-2008 technical agreement or GB/T 15712-2008 | 38MnVS, 49MnVS3, 48MnV, C70S6, 42MnVBS, 40Mnvs, 36MnVN, etc. | Automobile, construction machinery, etc. |

| Continuous casting round billet | Ф360 Ф400 Ф500 Ф600 |

GB/T 1591-2008 GB/T 699-1999 GB/T 3077-1999 GB/T API GB/T 1299-2000 GB/T 18254-2002 and technical agreement for users |

High strength low alloy steel, carbon constructional quality steel, alloy constructional steel, pipe steel billet, low alloy tool steel, bearing steel, etc. | Forging, pipe billet and various round forging steel |

| Continuous casting billet | 150 x 150 160 x 160 220 x 260 370 x 490 sections |

Technical agreement | High strength low alloy steel, carbon constructional quality steel, alloy constructional steel, low alloy tool steel, bearing steel, spring steel, etc. | Hot rolling, forging and various round forging steel |

| Other materials | Ф14~Ф130 | Technical assistance agreement | Cooperative develop new assortments and new kinds of steel |

Customized Alumina Ceramic Lined Project

Sort:99

High Chromium Alloy Lined Pipe

Sort:99

Sort:0

Wear-Resistant Hardfacing Liner Plate

Sort:0