The swing check valve is a high-performance non-return valve designed for robust backflow prevention in industrial pipelines, ensuring unidirectional flow for water, oil, gas, and chemical systems.

The swing check valve is a high-performance non-return valve designed for robust backflow prevention in industrial pipelines, ensuring unidirectional flow for water, oil, gas, and chemical systems.

Swing check valves are among the most widely used types of check valves. They ensure reliable one-way flow, preventing backflow with a simple and robust design. The swinging disc offers minimal resistance and allows full, unobstructed flow.

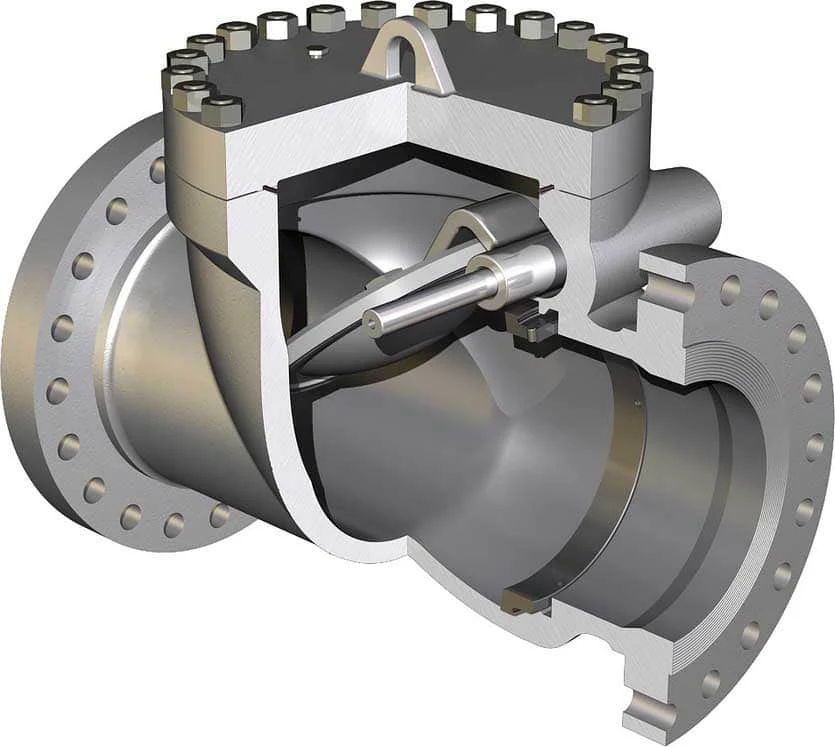

A swing check valve consists of a body, a bonnet, and a hinged disc. The disc swings away from the seat to permit forward flow, and returns to the seat when upstream flow stops, automatically preventing backflow.

The Swing Check Valve is a high-performance non-return valve designed for robust backflow prevention in industrial pipelines, ensuring unidirectional flow for water, oil, gas, and chemical systems. Featuring a hinged disc that swings open with forward flow and closes automatically against reverse flow, this valve protects pumps, compressors, and piping from damage caused by backpressure. Constructed from durable materials like ASTM A216 WCB carbon steel, ASTM A351 CF8M stainless steel, or ductile iron, with optional coatings such as epoxy or 3LPE, it offers exceptional corrosion resistance, making it ideal for backflow prevention valve applications in oil and gas, water treatment, and power generation industries.

Compliant with API 594 for check valves and ASME B16.34 for manufacturing, the swing check valve is available in sizes from 2" to 60" (DN50 to DN1500) with flanged, wafer, or butt-weld end connections per ASME B16.5 and B16.25. It supports pressure ratings up to PN40 (ANSI Class 150-600) and temperatures from -29°C to 425°C, with seat options like metal-to-metal for high temperatures or resilient EPDM/Viton for bubble-tight sealing in low-pressure systems. The full-bore design minimizes pressure drop (Cv values up to 15,000), optimizing flow efficiency in high-throughput industrial flow control applications. Certifications such as API 6D for pipeline valves, NSF 61 for potable water, and NACE MR0175 for sour service ensure versatility and reliability.

The valve’s robust construction includes a one-piece body and a heavy-duty hinge pin, reducing leak paths and ensuring durability under high-pressure conditions. Its corrosion resistant swing valve properties are enhanced by coatings that protect against rust, chlorides, and abrasive media, extending service life up to three times longer than uncoated valves in harsh environments like seawater or chemical processing. Rigorous testing per API 598, including hydrostatic shell tests at 1.5x rated pressure and seat leakage verification, confirms zero-leakage performance, while nondestructive examinations (RT, UT, MT) ensure structural integrity. With tensile strengths above 485 MPa, the valve withstands cyclic loading and thermal cycling in non-return valve duties.

Compared to dual-plate or lift check valves, the swing check valve offers a simpler design with lower maintenance needs, particularly in large-diameter, high-flow systems. Its gravity-assisted or spring-loaded disc ensures reliable closure without external actuation, reducing operational costs in backflow prevention valve setups. Optional features like renewable seats, soft seals for low-pressure applications, or extended bonnets for high-temperature insulation enhance adaptability for petrochemical refineries, HVAC systems, and marine pipelines. The valve’s ability to handle viscous fluids and slurries without chattering makes it a preferred choice for demanding applications.

Addressing challenges like backflow contamination, pipeline erosion, and equipment failure, the swing check valve incorporates a robust hinge mechanism and durable seals to ensure long-term performance. Its compatibility with global flange standards (ANSI, DIN, JIS) and coatings like FBE or PTFE ensures applicability in diverse environments, from buried pipelines to offshore platforms. Whether preventing reverse flow in boiler feed systems or protecting municipal water lines, the Swing Check Valve delivers cost-effective, reliable industrial flow control with minimal maintenance for global industrial operations.

Engineered for robust backflow prevention with durable materials and low-maintenance design.

Check valves are essential components that ensure safe and efficient operation of fluid systems by controlling flow direction and preventing backflow.

Permits fluid flow in one direction and automatically closes to prevent backflow in the opposite direction.

Uses hinged or spring-loaded flaps, discs, or pistons that open with forward flow and close with backflow.

Includes swing, lift, ball, and diaphragm check valves, each suited for different applications and conditions.

Widely used in water, wastewater, oil & gas, HVAC, and many other industrial applications.

Helps avoid sudden pressure surges caused when fluid flow is abruptly stopped.

Simple and reliable design ensures long-term efficiency with minimal upkeep.

Check valves are one-way valves that allow fluid to flow in a single direction and automatically prevent backflow. They are widely used in pipelines to protect pumps, piping, and other equipment. Backflow preventers apply additional pressure to ensure water flows only one way, providing extra protection for drinking water systems.

Allows fluid to flow in one direction and automatically prevents backflow.

Protects pumps, piping, and other equipment.

Check Valve: Simple, hinged or spring-loaded disc.

Backflow Preventer: Uses pressure and fail-safes to protect drinking

water.

Hinged disc swings open to allow forward flow and closes to prevent backflow.

Low turbulence and low pressure drop.

Piston or ball lifts from the seat to allow flow.

Suitable for high-pressure and high-velocity systems; can be installed horizontally or

vertically.

Ball Check, Butterfly Check, and Tilting-Disk Check valves.

Each design is optimized for specific applications and conditions.

- Unidirectional flow control

- Low maintenance

- Prevents water hammer

- Wide range of sizes & materials

- Versatile in water, oil, gas, and HVAC systems

| Feature | Check Valve | Backflow Preventer |

|---|---|---|

| Primary Function | Allows flow in one direction; prevents reverse flow automatically | Prevents contamination of drinking water; ensures flow only in one direction using pressure & fail-safes |

| Mechanical Design | Hinged disc, flap, piston, or ball opens with flow and closes with backflow | Multiple valves, check mechanisms, or air gaps to enforce one-way flow |

| Application | Pipelines, pumps, HVAC, water & wastewater, oil & gas | Potable water supply, irrigation, hospitals, schools, commercial buildings |

| Pressure Handling | Medium to high pressure; depends on valve type | High reliability; designed for pressurized systems to prevent contamination |

| Maintenance | Low; simple design, few moving parts | Moderate; more components, periodic inspection recommended |

| Reliability | Good for general use; may fail under extreme conditions | Highly reliable; multiple fail-safes for drinking water protection |

Comprehensive list of key international valve standards from major organizations, updated as of 2025.

| Organization | Standard | Description |

|---|---|---|

| ANSI | American National Standards Institute | General industrial standards |

| API | American Petroleum Institute | Standards for oil and gas industry |

| ASME | American Society of Mechanical Engineers | Boiler and pressure vessel codes |

| BS | British Standards | UK national standards |

| GB, JB, HG | China Valve Standards | Chinese national and industry standards |

| FCI | Fluid Control Institute | Standards for fluid control and conditioning equipment |

American National Standards Institute

| Code | ANSI Standard Name |

|---|---|

| ANSI A126 | Grey Iron Castings for Valves, Flanges, and Pipe Fittings |

| ANSI A181 | Forged or Rolled Steel Pipe Flanges, Forged Fittings, and Valves and Parts for General Service |

| ANSI B16.10 | Face-to-Face and End-to-End Dimensions of Valves |

| ANSI B16.34 | Valves - Flanged, Threaded, and Welding End |

| ANSI B16.5 | Pipe Flanges and Flanged Fittings |

| ANSI/FCI 70-2 | Control Valve Seat Leakage |

| ANSI B127.1 | Constant-Level Oilers |

American Petroleum Institute

| Code | API Standard Name |

|---|---|

| API 526 | Flanged Steel Pressure-Relief Valves |

| API 527 | Seat Tightness of Pressure Relief Valves |

| API 594 | Check Valves: Flanged, Lug, Bolted Bonnet |

| API 595 | Cast Iron Gate Valves - Flanged Bonnet |

| API 597 | Steel Venturi Gate Valves - Flanged and Welding Ends |

| API 598 | Valve Inspection and Testing |

| API 599 | Steel and Ductile Iron Plug Valves |

| API 600 | Bolted Bonnet Steel Gate Valves for Refinery Service |

| API 602 | Compact Steel Gate Valves - Flanged, Threaded, and Welding Ends |

| API 603 | Corrosion-Resistant Gate Valves - Flanged Ends |

| API 604 | Ductile Iron Gate Valves - Flanged Ends |

| API 607 | Fire Test for Quarter-Turn Valves |

| API 608 | Metal Ball Valves - Flanged, Threaded, and Welding Ends |

| API 609 | Butterfly Valves: Double Flanged, Lug- and Wafer-Type |

| API 6D | Pipeline and Piping Valves |

| API 6FA | Fire Test for Valves |

| API RP 574 | Inspection Practices for Piping System Components |

| API RP 576 | Inspection of Pressure-Relieving Devices |

American Society of Mechanical Engineers

| Code | ASME Standard Name |

|---|---|

| ASME A105/A105M | Carbon Steel Forgings for Piping Applications |

| ASME A181/A181M | Carbon Steel Forgings, for General-Purpose Pipes |

| ASME A182/A182M | Forged or Rolled Alloy and Stainless Steel Pipe Flanges, Forged Fittings, and Valves and Parts for High-Temperature Service |

| ASME A350/A350M | Carbon and Low-Alloy Steel Forgings for Low-Temperature Service |

| ASME A694/A694M | Carbon and Alloy Steel Forgings for Pipe Flanges, Fittings, Valves, and Parts for High-Pressure Transmission Service |

| ASME B16.5 | Pipe Flanges and Flanged Fittings: NPS 1/2 Through NPS 24 Metric/Inch Standard |

| ASME B16.10 | Face-to-Face and End-to-End Dimensions of Valves |

| ASME B16.11 | Forged Fittings, Socket-Welding and Threaded |

| ASME B16.34 | Valves - Flanged, Threaded, and Welding End |

| ASME B31.1 | Power Piping |

| ASME B31.3 | Process Piping |

| ASME F1508 | Standard Specification for Angle Style, Pressure Relief Valves for Steam, Gas, and Liquid Services |

| ASME F1565 | Pressure-Reducing Valves for Steam Service |

British Standards Institution

| Code | British Standard Name |

|---|---|

| BS 1212 | Float Operated Valves - Automatic Valves (Including Float Valves) for Tanks, Cisterns, Hot-Water Cylinders and Feed Cisterns |

| BS 1414 | Specification for Steel Wedge Gate Valves (Flanged and Butt-Welding Ends) for the Petroleum, Petrochemical and Allied Industries |

| BS 1552 | Specification for Control Plug Cocks for Low Pressure Gases |

| BS 1868 | Specification for Steel Check Valves (Flanged and Butt-Welding Ends) for the Petroleum, Petrochemical and Allied Industries |

| BS 1873 | Specification for Steel Globe and Globe Stop and Check Valves (Flanged and Butt-Welding Ends) for the Petroleum, Petrochemical and Allied Industries |

| BS 1952 | Specification for Copper Alloy Gate Valves for General Purposes |

| BS 2080 | Specification for Face-to-Face, Centre-to-Face, End-to-End and Centre-to-End Dimensions for Flanged and Butt-Welding End Steel Valves for the Petroleum, Petrochemical and Allied Industries |

| BS 2995 | Specification for Cast and Forged Steel Wedge Gate, Globe, Check and Plug Valves Screwed and Socket-Welding Sizes 1/2 in and Smaller for the Petroleum Industry |

| BS 3464 | Specification for Cast Iron Gate Valves for General Purposes |

| BS 5150 | Specification for Cast Iron Wedge and Double Disk Gate Valves for General Purposes |

| BS 5151 | Specification for Cast Iron Gate (Parallel Slide) Valves for General Purposes |

| BS 5152 | Specification for Cast Iron Globe and Globe Stop and Check Valves for General Purposes |

| BS 5153 | Specification for Cast Iron Check Valves for General Purposes |

| BS 5154 | Specification for Copper Alloy Globe, Globe Stop and Check, Check and Gate Valves for General Purposes |

| BS 5155 | Specification for Butterfly Valves for General Purposes |

| BS 5156 | Specification for Screw-Down Diaphragm Valves for General Purposes |

| BS 5157 | Specification for Steel Gate (Parallel Slide) Valves for General Purposes |

| BS 5159 | Specification for Cast Iron and Carbon Steel Ball Valves for General Purposes |

| BS 5160 | Specification for Steel Globe Valves, Globe Stop Valves, Stop and Check Valves and Lift Type Check Valves |

| BS 5351 | Specification for Steel Ball Valves for Petroleum, Petrochemical and Allied Industries |

| BS EN 12266-1 | Industrial Valves - Testing of Metallic Valves Part 1: Pressure Tests - Test Procedures |

China National Standards

| Code | GB Standard Name | Adopting Standard |

|---|---|---|

| GB 12220 | General Valve - Marking | ISO 5209 |

| GB 12221 | Flanged Ends Metal Valve - Face-to-Face Dimensions | ISO 5752 |

| GB 12222 | Multi-Turn Valve - The Connection of the Driving Device | ISO 5210/1-3 |

| GB 12223 | Part-Turn Valve - The Connection of the Driving Device | ISO 5211/1-3 |

| GB 12224 | Steel Valve - General Requirements | ANSI B16.34 |

| GB 12225 | General Valve - Copper Alloy Casting Ware Technology Requirements | ASTM B584 |

| GB 12226 | General Valve - Gray Cast Iron Technology Requirements | ISO 185, BS 1452 |

| GB 12228 | General Valve - Carbon Forging Steel Technology Requirements | ASTM A105, A181 |

| GB 12229 | General Valve - Carbon Casting Steel Technology Requirements | ASTM A703 |

| GB 12230 | General Valve - Austenitic Casting Steel Technology Requirements | ASTM A351 |

| GB 12232 | General Valve - Flanged Ends Iron Gate Valve | ISO 5996-1982, API 595 |

| GB 12233 | General Valve - Iron Gate Valve and Lift Check Valve | BS 5152, 5153 |

| GB 12234 | General Valve - Flanged and Butt-Welding Ends Copper Gate Valve | API 600 |

| GB 12237 | General Valve - Flanged and Butt-Welding Ends Steel Ball Valve | ISO 7121, API 607 |

| GB 12238 | General Valve - Flanged and Wafer Ends Butterfly Valve | BS 5155 |

| GB 12239 | General Valve - Diaphragm Valve | BS 5156, NFE 29 |

| GB 12240 | General Valve - Iron Plug Valve | API 593 |

| GB 12241 | Safety Valve - General Requirements | ISO 4126 |

| GB 12242 | Safety Valve - Characteristic Testing Solution | ANSI/ASME PTC 25.3 |

| GB 12243 | Direct Spring-Loaded Safety Valve | JIS B 8210 |

| GB 12244 | Pressure Reducing Valve - General Requirements | JIS B 8372, B8410 |

| GB 12245 | Pressure Reducing Valve - Characteristic Testing Solution | JIS B 8372, B8410 |

| GB 12246 | Pilot Operated Pressure Reducing Valve | JIS B 8372, DSS 405 |

| GB 12247 | Steam Trap Valve - Classification | ISO 6704 |

| GB 12248 | Steam Trap Valve - Technology Terms | ISO 6552 |

| GB 12249 | Steam Trap Valve - Marking | ISO 6553 |

| GB 12250 | Steam Trap Valve - Face-to-Face Dimensions | ISO 6554 |

| GB 12251 | Steam Trap Valve - Testing Solution | ISO 6948, 7841, 7842 |

| GB/T 13927 | General Valve - Pressure Testing | ISO 5208 |

| JB/T 6899-93 | Valve Fire-Proof Test | ISO 10497 |

| JB/T 7927-95 | Valve Casting Steelware Out-Form Quality Requirements | MSS SP-55 |

| ZBJ 16006-90 | Inspection and Testing of Valve | API 598 |

| Code | GB Standard Name |

|---|---|

| GB 12227 | General Valve - Ductile Cast Iron Technology Requirements |

| GB 12235 | General Valve - Flanged Steel Stop and Lift Check Valve |

| GB 12236 | General Valve - Steel Swing Check Valve |

| GB/T 13932 | General Valve - Iron Swing Check Valve |

| GB/T 15185 | Iron and Copper Ball Valve |

| GB/T 15188.1 | Valve Face-to-Face Dimensions - Butt-Welding Ends Valve |

| GB/T 15188.2 | Valve Face-to-Face Dimensions - Wafer Ends Valve |

| GB/T 15188.3 | Valve Face-to-Face Dimensions - Female Screw-Down Valve |

| GB/T 15188.4 | Valve Face-to-Face Dimensions - Male Screw-Down Valve |

| JB 93 | Handle |

| JB/T 450 | PN16-32.0 MPa Forging Angle Type High-Pressure Valve, Fastener, and Technology Requirements |

| JB/T 7745-95 | Pipeline Ball Valve |

| JB/T 8527-97 | Metal Sealing Butterfly Valve |

| JB/T 8473-96 | Instrument Valve Series |

| ZBJ 16004-88 | Reducing Valve Type and Basing Coefficient |

| ZBJ 16007-90 | Steam Trap Valve Technology Terms |

| ZBJ 16009-90 | Valve Pneumatic Actuator Technology Terms |

Standards for fluid control and conditioning equipment

The Fluid Control Institute (FCI) provides standards to assist in understanding and using control valves, solenoid valves, and regulators.

| Code | FCI Standard Name |

|---|---|

| ANSI/FCI 70-2 | Control Valve Seat Leakage |

| ANSI/FCI 70-3 | Control Valve Aerodynamic Noise Prediction |

| ANSI/FCI 91-1 | Qualification of Control Valve Stem Seals |

| ANSI/FCI 85-1 | Method of Determining the Thermal Expansion of a Filled Thermal System |

| FCI 68-2 | Procedure in Rating Flow and Pressure Characteristics of Solenoid Valves for Liquid Service |

| FCI 75-1 | Test Conditions and Procedures for Measuring Electrical Characteristics of Solenoid Valves |

| FCI 82-1 | Recommended Methods for Testing and Classifying the Water Hammer Characteristics of Electrically Operated Valves |

| ANSI/FCI 69-1 | Pressure Ratings of Traps |

Upstream, midstream, and downstream operations, including drilling, refining, and transportation.

Handling corrosive and hazardous chemicals in various chemical plants.

Steam, water, and fuel systems in thermal, nuclear, and hydroelectric plants.

Municipal water supply, wastewater treatment, and industrial water management.

Heating, ventilation, and air conditioning systems in commercial and industrial buildings.

Sterile and hygienic applications, precise flow control in sensitive industries.

API 6D & API 594 Swing Check Valve

Sort:0

Forged Lift / Piston Check Valve

Sort:0

Rubber Seal Dual Plate Check Valve

Sort:0

Customized Alumina Ceramic Lined Project

Sort:99

High Chromium Alloy Lined Pipe

Sort:99

Sort:0