EN 10305-1 E355 +C Pipe, Seamless Precision Steel Tube, Cold Drawn E355 Tubing, Hydraulic Precision Pipe, EN 10305 Seamless Tube

En 10305-1 specifies seamless cold drawn precision steel tubes of circular cross-section for precision applications in hydraulic and pneumatic systems.

EN 10305-1 E355 +C Pipe, Seamless Precision Steel Tube, Cold Drawn E355 Tubing, Hydraulic Precision Pipe, EN 10305 Seamless Tube

En 10305-1 specifies seamless cold drawn precision steel tubes of circular cross-section for precision applications in hydraulic and pneumatic systems. grade e355 +c (cold drawn/hard condition) offers high strength and dimensional accuracy for mechanical engineering and automotive uses. sizes od 6-420 mm, wt 1-50 mm, lengths up to 12 m.

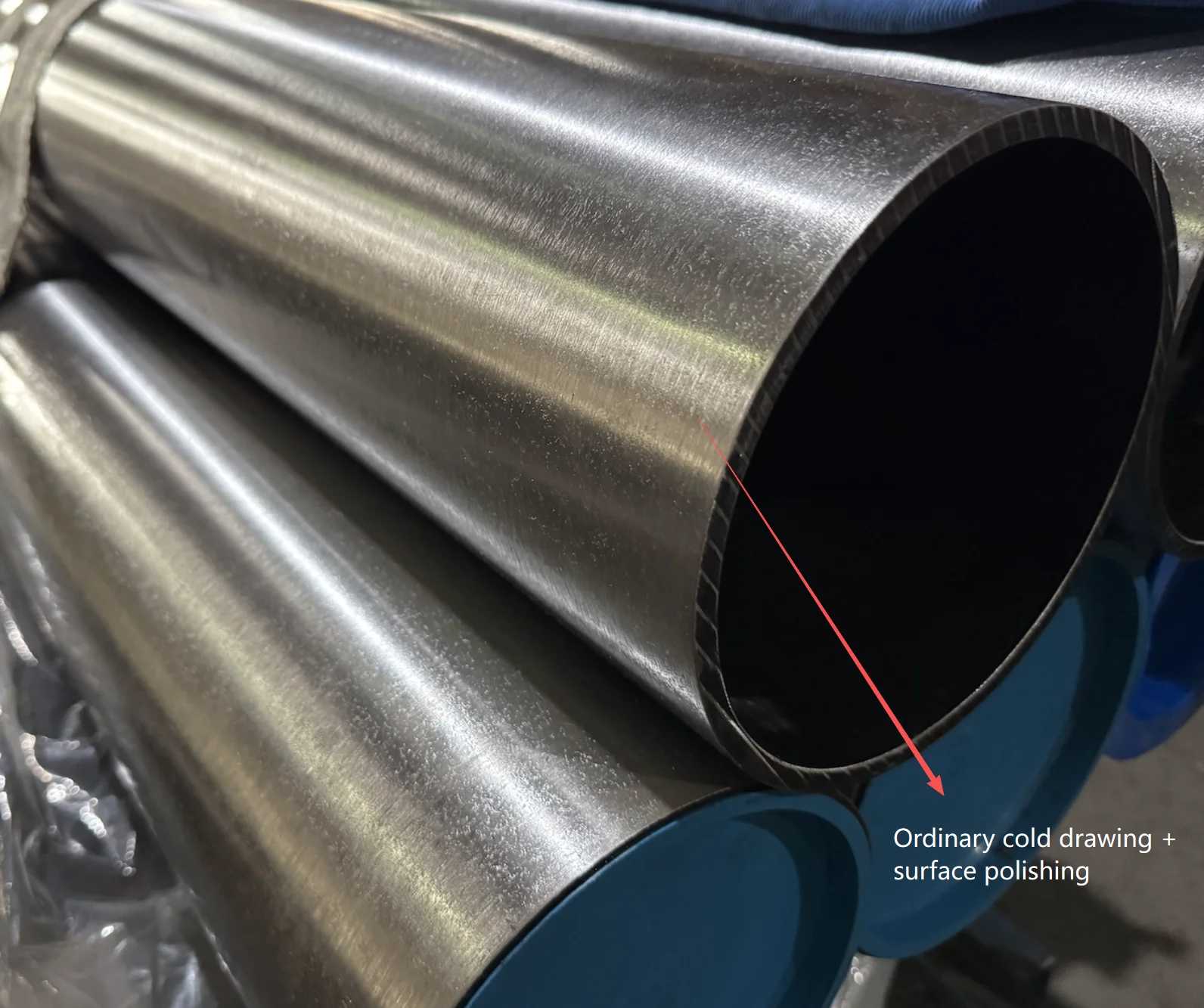

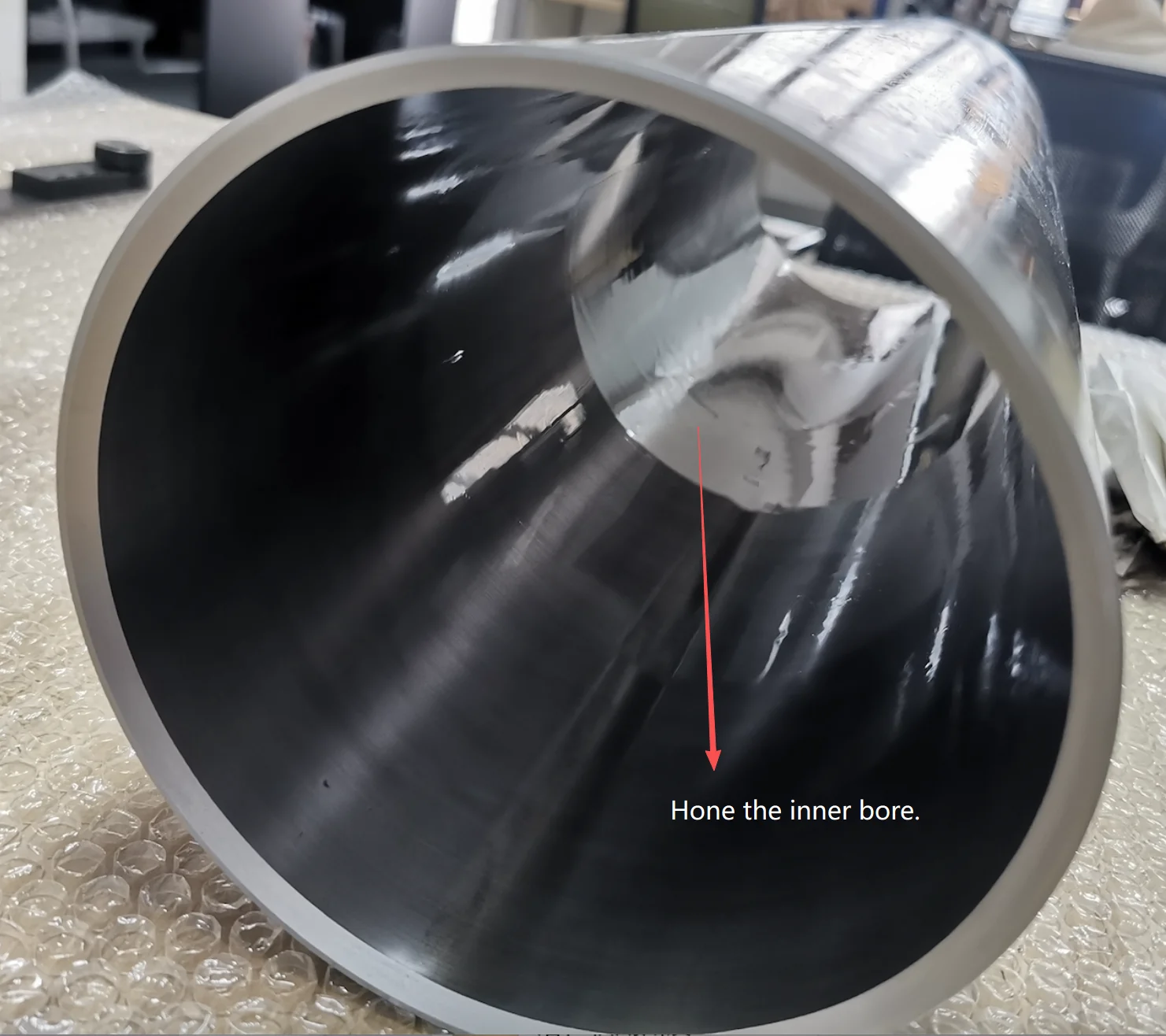

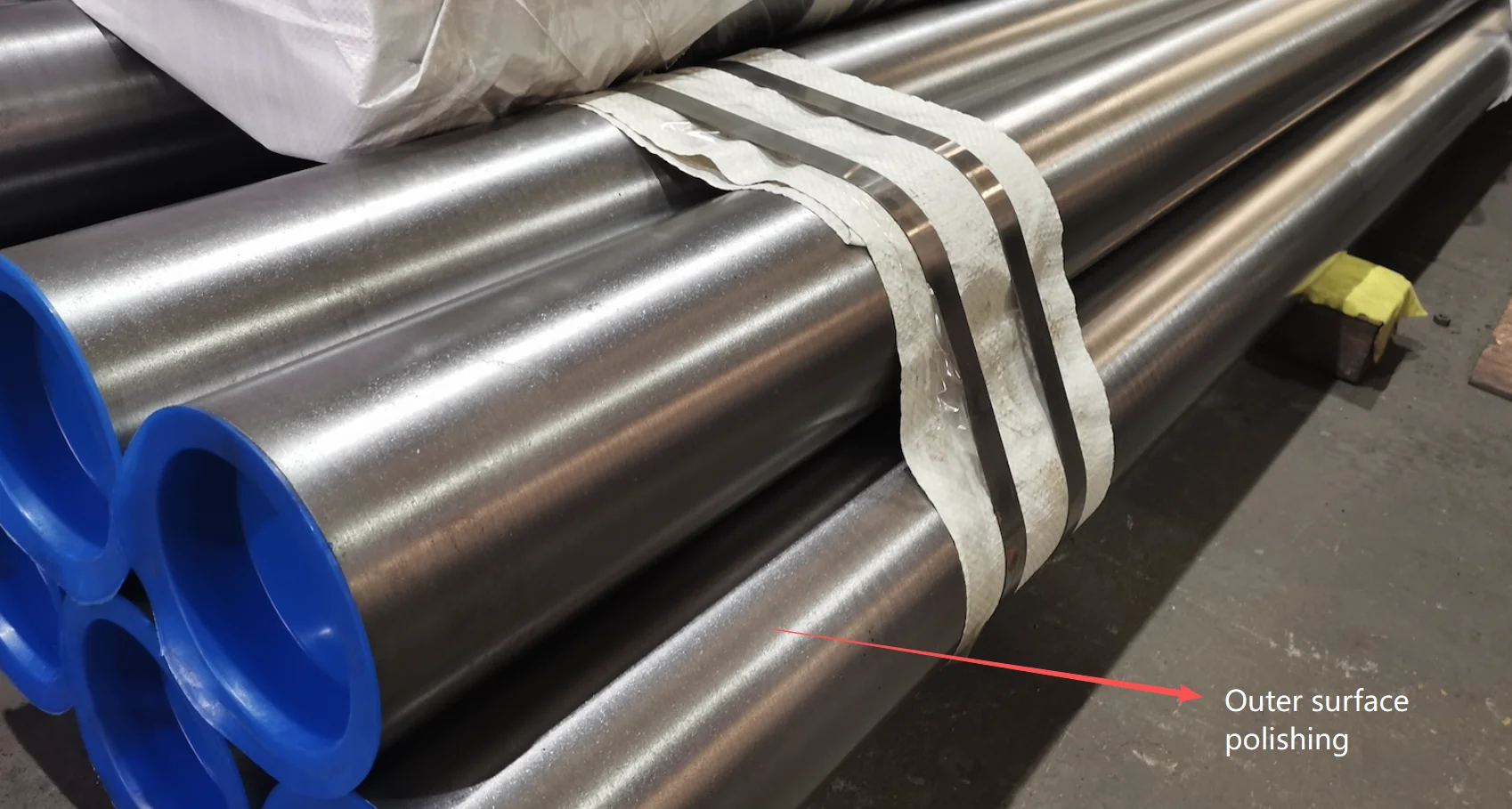

EN 10305-1 covers seamless cold drawn steel tubes for precision applications, ensuring tight tolerances and excellent surface quality. E355 is a non-alloy quality steel grade with good weldability and formability. The "+C" condition indicates cold drawn/hard, providing higher strength without heat treatment.

These pipes are ideal for hydraulic/pneumatic cylinders, machinery components, and automotive parts where dimensional accuracy and mechanical performance are critical.

EN 10305-1 specifies seamless cold drawn precision steel tubes of circular cross-section for precision applications in hydraulic and pneumatic systems. Grade E355 +C (cold drawn/hard condition) offers high strength and dimensional accuracy for mechanical engineering and automotive uses. Sizes OD 6-420 mm, WT 1-50 mm, lengths up to 12 m.

| Element | E355 (EN 10305-1) |

|---|---|

| C | ≤0.22 |

| Mn | 0.25-1.60 |

| P | ≤0.025 |

| S | ≤0.025 |

| Si | ≤0.55 |

| Property | Value |

|---|---|

| Tensile Strength | 490-630 MPa |

| Yield Strength (min) | ≥355 MPa |

| Elongation (min) | 8-12% |

| Hardness (HB max) | ≤217 |

| Parameter | Range |

|---|---|

| Outside Diameter (OD) | 6–420 mm |

| Wall Thickness (WT) | 1–50 mm |

| Length (L) | Max 12,000 mm |

| OD Tolerance | ±0.1 mm (typical) |

| WT Tolerance | ±0.05 mm (typical) |

Standard for seamless carbon steel boiler and superheater tubes designed for high-pressure, high-temperature service environments.

These internationally recognized standards ensure that pipes meet specific requirements for dimensions, tolerances, chemical composition, and mechanical properties, guaranteeing uniformity, interchangeability, and high performance across various industrial applications. They are widely used for conveying fluids, gases, and solids, as well as for structural purposes in demanding environments.

Fully adheres to comprehensive DIN and EN standards, ensuring consistent quality and performance across all batches.

Suitable for construction, oil and gas, automotive, and general manufacturing industries.

Manufactured with precise dimensions and tight tolerances for easy integration into complex systems.

Available in various material grades including non-alloy, alloy, and stainless steel options.

Rigorous quality control including visual inspection, dimensional checks, and non-destructive testing.

Widely recognized standards facilitate international trade and project execution worldwide.

European steel standards harmonize national systems via CEN/TC 459 (formerly ECISS) and its subcommittees, ensuring consistent technical delivery, testing, and classification across the EU.

Responsible for standardization of iron & steel products—wires, tubes, sheets, forgings—under pressure equipment directives.

European standards adopt national prefixes: BS EN (UK), DIN EN (Germany), SIS EN (Sweden), etc.

A curated list of long-tail keywords for DIN EN steel pipes, covering seamless and welded tubes for various applications, presented in a two-column layout.

Note: DIN EN standards cover a range of seamless and welded steel pipes for various applications. For detailed specifications, refer to the relevant DIN EN standard or contact a certified supplier.

DIN 1629 is a German standard specifying requirements for seamless circular steel tubes made of non-alloy steels. These tubes are typically used in mechanical and general engineering applications, as well as for manufacturing vessels and pipework, but are not suitable for heat treatment or high-pressure applications.

DIN 1629 covers seamless circular tubes of non-alloyed steel (grades St 37.0, St 44.0, St 52.0), used in general mechanical engineering—not for pressure or heat-treated applications.DIN 2391 is a German standard that specifies dimensions and technical delivery conditions for seamless precision steel tubes, particularly those used in mechanical and automotive engineering. These tubes are known for their high dimensional accuracy and smooth surface finish, making them suitable for applications like hydraulic and pneumatic systems.

DIN 2391 specifies seamless precision steel tubes (grades ST35, ST45, ST52), cold-finished for mechanical and automotive engineering use.DIN 2458 covers a range of welded steel pipes, defining their dimensions (outer diameter and wall thickness), material grades (like St 37.0, St 44.0, St 52.0), manufacturing processes (ERW and SAW), and other characteristics.

DIN 2458 defines welded black steel pipes (St37.2) for construction, water transport, and mechanical systems, including welded wall thickness and OD tolerances.

DIN EN Steel Pipes are widely used in industries requiring high-pressure resistance, corrosion resistance, and precision for seamless and welded applications.

Used for transporting combustible fluids, ensuring high-pressure piping reliability.

Employed in boilers, offering seamless steel tubes for high-temperature conditions.

Utilized for handling corrosive fluids, ensuring corrosion resistance.

Applied in precision components like fuel systems, using precision steel tubes.

Used in structural applications, offering abrasion resistance and strength.

Employed in high-pressure systems, ensuring seamless steel tubes reliability.

EN 10305-1 Seamless Precision Steel Tube

Sort:11

DIN 1629 Carbon Seamless Steel Pipes

Sort:0

DIN 2391 Seamless Precision Steel Tubes

Sort:0

Sort:0

DIN 17175 Seamless Steel Tubes

Sort:0

Tubo Preto DIN 2458 em Aço Carbono para Caldeiras e Estruturas

Sort:0

Customized Alumina Ceramic Lined Project

Sort:99

High Chromium Alloy Lined Pipe

Sort:99

Sort:0