High Efficiency Evaporation & Protection

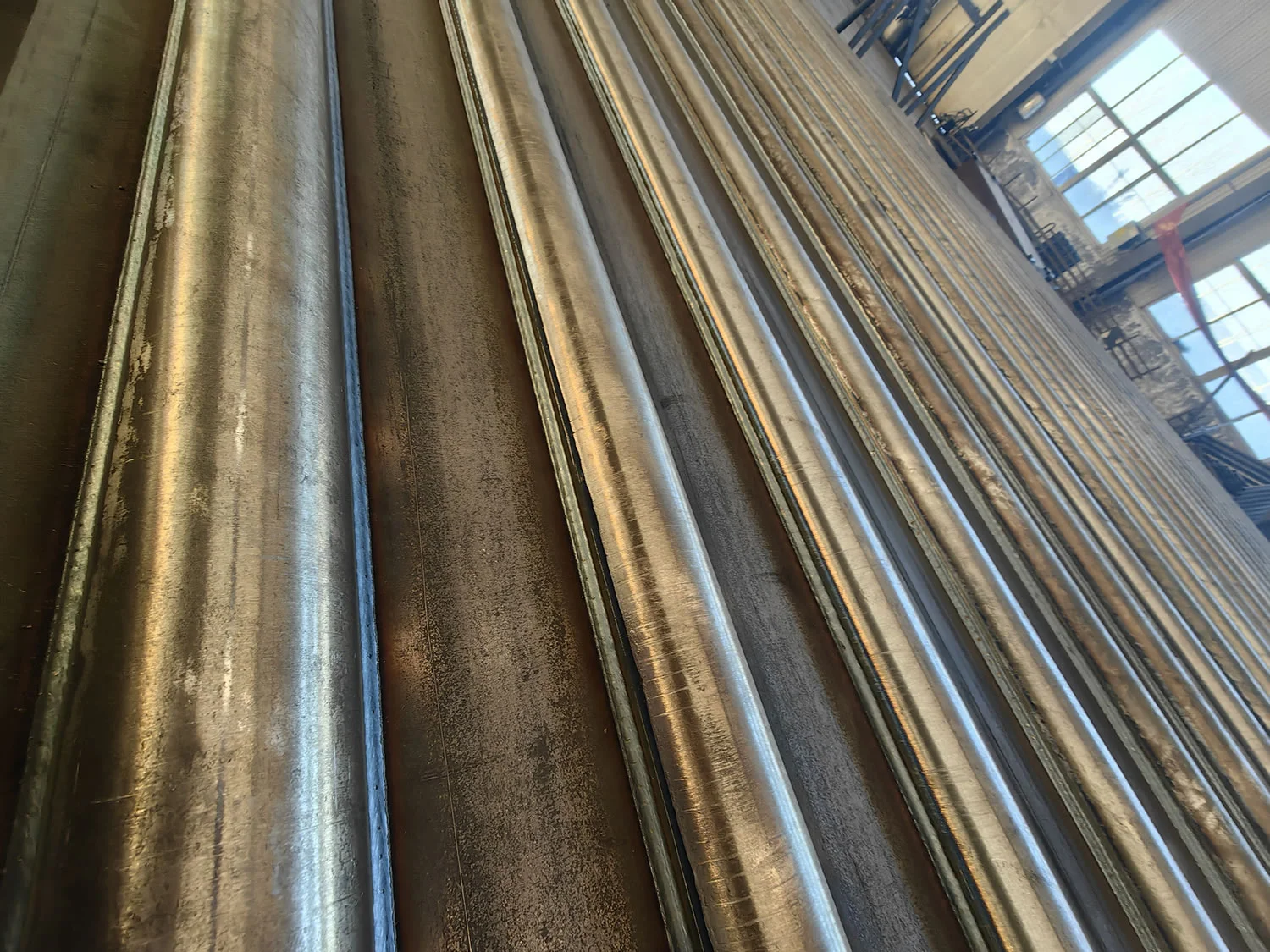

Boiler water wall panels are high-efficiency heat absorbing tube assemblies designed for modern industrial boilers.

High Efficiency Evaporation & Protection

Boiler water wall panels are high-efficiency heat absorbing tube assemblies designed for modern industrial boilers. they improve heat transfer, protect furnace walls and support stable steam generation.

Water wall panels are used in modern industrial boilers to replace steam generating tubes. They are designed to absorb high temperature radiant heat given off by the flame in the fuel chamber, and reduce heat loss caused by the air tightness.

We manufacture boiler tubes of the water wall panels in a variety of shapes and sizes to meet customer requirements, and all are processed using automatic fin to tube welding machines and large tube benders.

Materials: 20# Steel, SA192, SA106B, 15CrMoVG, 12Cr1MoV

Standards: ASME Code standard, GB Standard

Quality Inspection: MT, RT, Hydraulic test

Spot welds many rolled finned tubes into a sealed combined heating surface, which improves the airtightness of the furnace and reduces air leakage.

Welds pins of 20 to 25 mm in length and 6 to 12 mm in diameter on the water wall tube, then applies chrome ore refractory plastic to reduce heat absorption and increase combustion zone temperature. Suitable for difficult-to-ignite fuels and specific slag tapping furnaces.

Composed of a whole row of seamless steel pipes — the simplest structure.

Embedded in the inner wall of the furnace wall, single-sided heat absorption.

Installed in the middle of large boiler furnaces, dividing into two independent parts with both sides heated.

Processed using automatic fin to tube welding machines and large tube benders.

| Grade | C (%) | Si (%) | Mn (%) | P (% max) | S (% max) |

|---|---|---|---|---|---|

| ASTM A179 | 0.06–0.18 | - | 0.27–0.63 | 0.035 | 0.035 |

| ASTM A213 T11 | 0.05–0.15 | 0.50–1.00 | 0.30–0.60 | 0.025 | 0.025 |

| EN 10216-2 P235GH | 0.16 max | 0.35 max | 1.20 max | 0.025 | 0.020 |

Material: Commonly used materials are carbon steel, low alloy steel, stainless steel, copper, copper-nickel alloy, aluminum alloy, titanium, etc. In addition, there are some non-metallic materials, such as graphite, ceramics, polytetrafluoroethylene, etc. In the design, appropriate materials should be selected according to the working pressure, temperature and corrosiveness of the medium.

| Grade | Tensile Strength (MPa min) | Yield Strength (MPa min) | Elongation (% min) |

|---|---|---|---|

| ASTM A179 | 325 | 180 | 35 |

| ASTM A213 T11 | 415 | 205 | 30 |

| EN 10216-2 P235GH | 360–500 | 235 | 25 |

| Feature | Heat Exchange Tubes | Fluid Tubes | Superheater Tubes |

|---|---|---|---|

| Material Type | Carbon/Low-Alloy Steel | Carbon Steel | Carbon/Alloy Steel |

| Temperature Range | Up to 600°C | -40°C to 450°C | Up to 500°C |

| Tensile Strength (MPa) | 325–500 | 360–500 | 325–480 |

| Yield Strength (MPa) | 180–235 | 235–240 | 180–280 |

| Corrosion Resistance | High (with coatings) | Moderate (with coatings) | Moderate (with coatings) |

| Pressure Resistance | High (up to 25 MPa) | High (up to 30 MPa) | Moderate (up to 20 MPa) |

| Cost | Moderate | Moderate | Moderate |

| Applications | Heat exchangers, condensers | Fluid transport (oil, gas) | Superheaters, feedwater heaters |

| Key Advantage | High thermal conductivity | High-pressure fluid reliability | Thermal conductivity in boilers |

| Manufacturing Process | Seamless, heat-treated | Seamless, heat-treated | Seamless, cold-drawn |

Explore seamless heat exchange tubes with targeted long-tail keywords, covering specifications, applications, manufacturing, procurement, and dimensions for heat exchanger systems.

Note: Heat exchange tubes are designed for efficient heat transfer in demanding applications. For detailed specifications, refer to ASTM A179, A213, EN 10216-2, or contact a certified supplier.

Heat Exchange Tubes are vital for efficient heat transfer in power generation, petrochemical, and HVAC systems, ensuring optimal performance and durability.

Transfers heat in condensers and feedwater heaters.

Manages heat in chemical processing systems.

Facilitates heat transfer in heating and cooling units.

Handles corrosive fluids in heat exchangers.

Supports cooling systems in marine applications.

Recovers heat in industrial processes.

Ultra-long heat exchanger tubes

Sort:0

Customized Alumina Ceramic Lined Project

Sort:99

High Chromium Alloy Lined Pipe

Sort:99

Sort:0

Wear-Resistant Hardfacing Liner Plate

Sort:0