High Chromium Wear Resistant Cast Iron

Kmtbcr26 is a high chromium wear resistant cast iron with hardness up to hrc 65, ideal for severe abrasive applications in mining, cement and power plants.

High Chromium Wear Resistant Cast Iron

Kmtbcr26 is a high chromium wear resistant cast iron with hardness up to hrc 65, ideal for severe abrasive applications in mining, cement and power plants.

Extreme abrasion resistance for mining, cement, power generation and heavy-duty material handling systems.

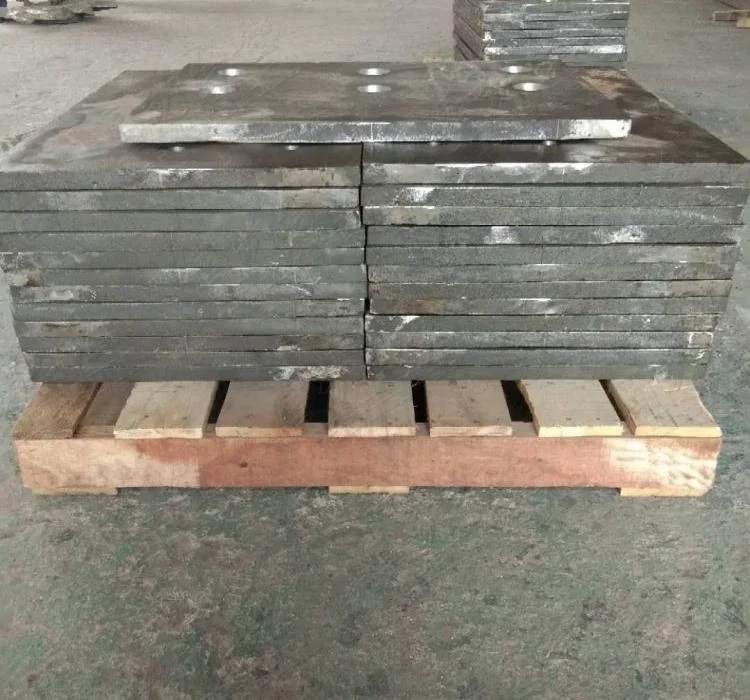

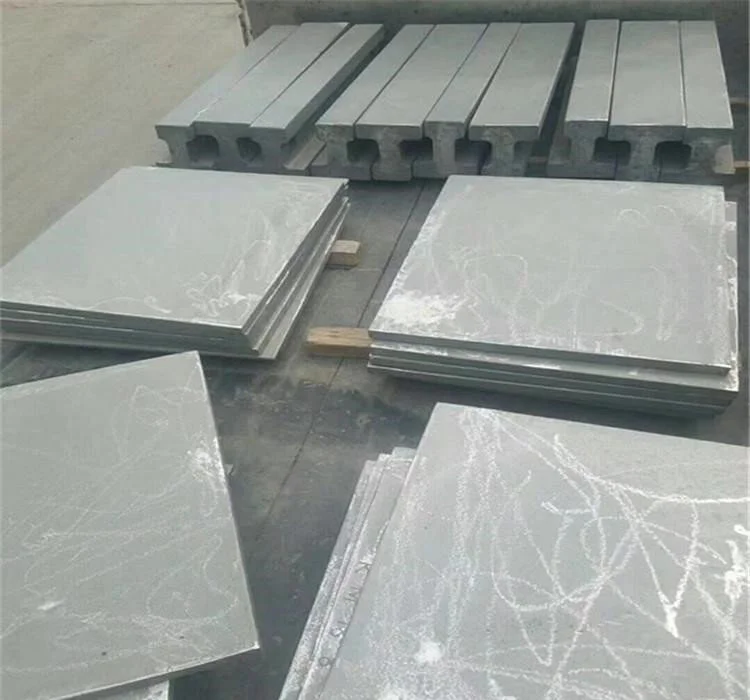

KmTBCr26 is a high chromium white cast iron specifically engineered for components exposed to intense abrasive wear.

The microstructure is dominated by hard chromium carbides, delivering outstanding resistance to sliding and impact abrasion.

Optimized for wear resistance rather than ductility, making it ideal for liners, plates and wear blocks.

Longer service life reduces replacement frequency and downtime, significantly lowering total operating cost.

Typical values for reference. Chemical composition can be optimized according to service conditions.

| C | Cr | Si | Mn | Mo | Ni |

|---|---|---|---|---|---|

| 2.6–3.2 | 24–28 | 0.5–1.5 | 0.5–1.5 | 0.5–1.5 | ≤1.0 |

| Hardness | HRC 58–65 |

|---|---|

| Wear Mechanism | High-stress abrasion / erosion |

| Impact Resistance | Low to medium |

| Recommended Service Temperature | ≤ 500°C |

Our high-temperature alloys, abrasion-resistant pipes, ceramic-lined systems and fittings provide exceptional durability in the most aggressive thermal, erosive and corrosive environments.

ZG35Cr24Ni7SiN is a high-performance heat-resistant cast alloy engineered for extreme thermal environments. It offers exceptional durability, oxidation resistance, and cost efficiency—making it the smart choice for demanding high-temperature applications.

Designed for continuous operation up to 1050°C, ZG35Cr24Ni7SiN maintains structural stability and mechanical strength even under prolonged thermal exposure.

High chromium and silicon content form a dense, protective oxide layer that significantly reduces metal loss and extends maintenance intervals.

Nitrogen alloying dramatically improves creep resistance and high-temperature strength, outperforming conventional Cr–Ni cast steels during long-term service.

Delivers performance comparable to high-Ni grades like ZG40Cr25Ni20 in many applications—at a significantly lower alloy cost.

Superior castability enables production of large, intricate one-piece components—reducing welds, joints, and potential failure points.

Selecting the right wear material is critical for service life and operating cost. Below is a practical comparison of common wear-resistant materials.

| Material | Typical Hardness | Wear Resistance | Impact Resistance | Service Temperature | Cost Level | Typical Applications |

|---|---|---|---|---|---|---|

| KmTBCr26 | HRC 58–65 | ★★★★★ | ★★ | ≤ 500°C | ★★★ | Severe abrasion liners, chutes, wear plates, mining & cement equipment |

| Ni-Hard (Ni-Hard 4) | HRC 55–60 | ★★★★ | ★★★ | ≤ 400°C | ★★★ | Impact + abrasion parts, mill liners, crusher components |

| Cr20 Cast Iron | HRC 50–58 | ★★★☆ | ★★☆ | ≤ 450°C | ★★ | Medium abrasion conditions, general wear parts |

| Hardfacing Overlay | HRC 55–62 | ★★★★☆ | ★★★ | ≤ 600°C* | ★★★★ | Local wear protection, repair and reinforcement |

Customized Alumina Ceramic Lined Project

Sort:99

High Chromium Alloy Lined Pipe

Sort:99

Sort:0

Wear-Resistant Hardfacing Liner Plate

Sort:0