- Seamless And Welded Solutions With Superior Corrosion Resistance

Stainless steel pipe is one of the more standardized materials resist corrosion due to a minimum 10.5% chromium content.

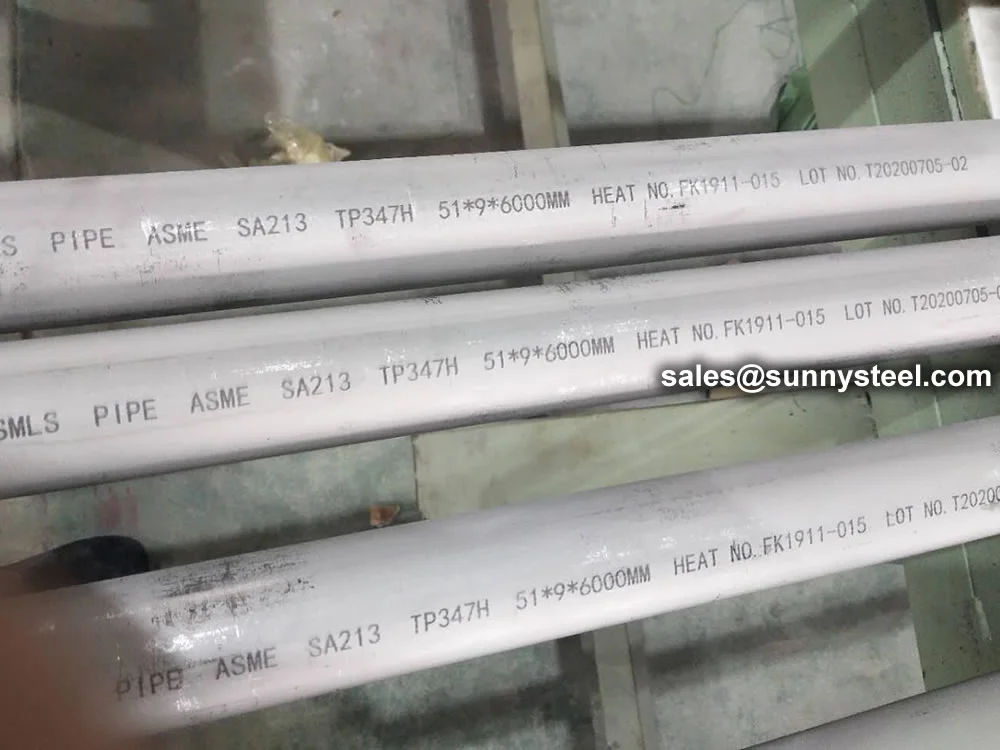

Stainless Steel Pipes are engineered for reliable fluid transport in demanding industrial environments, offering exceptional corrosion resistance and durability. Compliant with ASTM A312 for seamless and welded austenitic pipes and API 5L for oil and gas pipelines, these pipes are ideal for high-pressure applications up to 4500 psi and temperatures ranging from -196°C to 650°C. Grades like TP304/304L provide cost-effective corrosion resistance for general use, while TP316/316L excels in chloride-rich environments, such as marine or chemical processing, due to its superior pitting resistance. Seamless Stainless Pipes, produced via extrusion or rotary piercing, ensure structural integrity for critical systems, while Welded Stainless Pipes, formed from strip welding, offer cost-efficiency for larger diameters.

These Corrosion Resistant Pipes boast tensile strengths ≥515 MPa, yield strengths ≥205 MPa, and elongations up to 40%, supporting bending, flanging, and welding. Chromium (18-20%) forms a self-healing oxide layer, enhanced by nickel (8-14%) for ductility and molybdenum (in 316) for pitting resistance. Available in sizes from 1/8" to 36" (DN6 to DN900) and wall thicknesses from SCH 5S to XXH, they meet diverse needs, from oil and gas pipelines to food-grade systems. Surface finishes like mill, polished, or electropolished ensure compliance with sanitary standards for pharmaceuticals, while heat treatments enable cryogenic service. NACE MR0175 compliance supports sour service in oil and gas, resisting H2S and chlorides.

Seamless Stainless Pipes are preferred for high-pressure applications like boiler systems under ASME SA312, offering zero weld imperfections for enhanced safety. Welded Stainless Pipes suit low-to-medium pressure systems, such as water distribution or HVAC, with cost savings of up to 20% compared to seamless variants. Benefits include a lifespan of up to 50 years and 30-40% lower lifecycle costs versus carbon steel due to minimal maintenance. Custom options like cut-to-length or beveled ends facilitate integration into refineries, offshore platforms, or medical gas lines.

Compared to carbon steel, Stainless Steel Pipes provide 2-3 times better corrosion resistance, eliminating frequent painting in acidic or seawater environments. Unlike plastic pipes, they withstand extreme temperatures and pressures, ensuring reliability in industrial flows. Long-tail keywords like “seamless stainless steel pipe for oil and gas” or “welded stainless pipe for chemical processing” align with API 5L and NSF 61 standards. Rigorous testing—tensile, flattening, and hydrostatic—ensures compliance, with duplex grades like 2205 available for enhanced strength in aggressive conditions.

Addressing challenges like erosion in high-velocity flows and biofouling in water systems, these Industrial Stainless Pipes incorporate alloy enhancements like nitrogen for improved pitting resistance. Their 100% recyclability aligns with eco-friendly regulations, making them a sustainable choice. Whether transporting crude oil in refineries or potable water in municipal systems, Stainless Steel Pipes deliver unmatched strength, versatility, and performance for global industrial demands.

Engineered for robust fluid transport with superior corrosion resistance and strength.

Customized Alumina Ceramic Lined Project

Sort:99

High Chromium Alloy Lined Pipe

Sort:99

Sort:0

Wear-Resistant Hardfacing Liner Plate

Sort:0