Extensive Stock & In-house Processing

High-precision stainless steel strip in 304/316l ddq grades, metric thicknesses 0.

Extensive Stock & In-house Processing

High-precision stainless steel strip in 304/316l ddq grades, metric thicknesses 0.02-6mm per en 10088, with superior formability for deep drawing in automotive and food processing. custom widths up to 1000mm, pickled/annealed finishes—hygienic, weldable, and traceable for german chemical, construction, and refrigeration sectors seeking durable, low-work-hardening solutions.

Stainless steel strip is a durable, corrosion-resistant steel product manufactured from hot-rolled strip and pickled, primarily composed of iron, chromium (at least 10.5%), nickel, and manganese. It offers excellent thermodynamic properties, including specific heat capacity, melting point, thermal conductivity, and coefficient of linear expansion.

Precision-rolled for tight tolerances, it's ideal for deep drawing, stamping, and forming in demanding DE applications.

Thickness 0.02–6mm; Width 6–1000mm; Coil ID 406mm; Min lot 23kg. Finishes: Pickled, Annealed, Polished.

| Thickness (mm) | Width Range (mm) | Tolerance (mm) | Flatness (%) | Applications |

|---|---|---|---|---|

| 0.02–0.5 | 6–250 | ±0.05 | 3 | Precision springs, fasteners |

| 0.5–1.5 | 250–500 | ±0.08 | 3 | Deep-drawn washers, eyelets |

| 1.5–3.0 | 500–750 | ±0.10 | 3 | Computer parts, gaskets |

| 3.0–6.0 | 750–1000 | ±0.13 | 3 | Heat exchangers, aircraft components |

Why choose stainless steel for tactile and structural applications

Stainless steel offers exceptional durability, resisting rust, corrosion, and premature wear, ensuring long-lasting performance even in harsh environments.

Anti-slip textures enhance safety in wet areas, while stainless steel's natural reflectivity improves visibility for safer navigation.

Minimal maintenance is required—simple periodic cleaning ensures a long service life, reducing overall replacement costs.

Sunny Steel stainless steel strip product is manufactured and rolled to the tightest tolerances, allowing it to be used in applications where precision, strength, and durability are unparalleled.

We ensure that our high-quality coils are always available, supported by a strong distribution network, ensuring quick delivery and uninterrupted supply.

Versatile austenitic stainless steel strip for precision spring manufacturing, stampings, fasteners, and computer parts; high strength and formability; EN 1.4310.

Ideal stainless steel strip for corrosion resistance and high temperatures in general fabrication; balanced properties for diverse applications; EN 1.4301.

Deep draw quality stainless steel strip with higher nickel for severe forming; low work hardening for complex shapes; EN 1.4307.

Stainless steel strip for deep drawn and spun components; corrosion resistance like 304/L with reduced work hardening for eyelets and cold forming; EN 1.4303.

Premium austenitic stainless steel strip for severe deep draws; combines strength, corrosion resistance, and nickel-enhanced formability; EN 1.4404.

Stainless steel strip for sulfuric acid exposure and high temperatures; used in heat exchangers, boilers, and superheaters; EN 1.4438.

Titanium-stabilized austenitic stainless steel strip for high-temp applications; prevents intergranular corrosion in gaskets and aircraft parts; EN 1.4541.

Non-magnetic, columbium/tantalum-stabilized stainless steel strip for high-temp gaskets, aircraft, and chemical equipment; EN 1.4550.

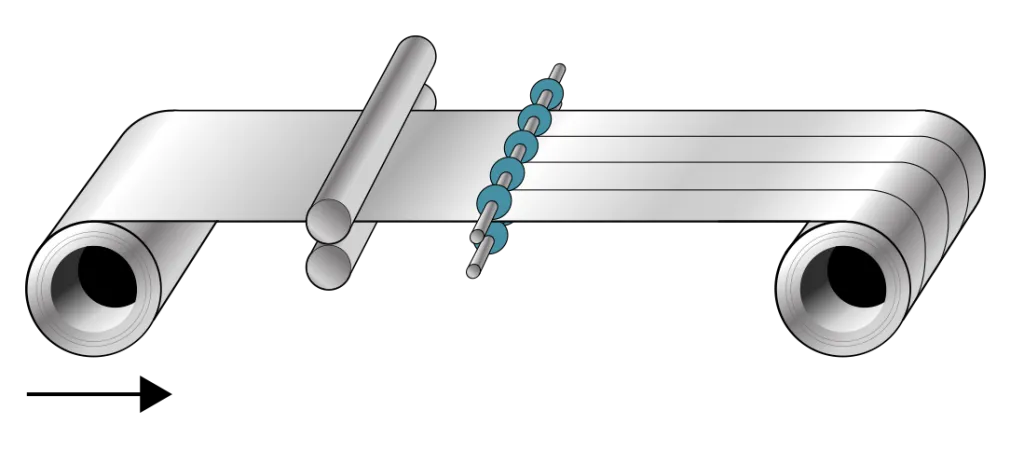

The production of stainless steel strip involves precise metallurgical and mechanical steps that ensure corrosion resistance, high strength, and accurate dimensional control.

The process begins with selecting high-quality raw materials including iron, chromium (at least 10.5%), nickel, and additional alloying elements such as carbon, manganese, silicon, molybdenum, and copper. These elements are precisely proportioned to achieve the required stainless steel grade.

The blended raw materials are melted in an electric arc furnace or induction furnace at temperatures around 1600°C. During melting, impurities and gases are removed while the chemical composition is adjusted to precise specifications.

The molten stainless steel is poured into a continuous casting machine, where it forms a semi-finished billet. Controlled cooling and mold temperature directly influence the strip's internal structure and surface quality.

The billet is hot rolled to reduce thickness and achieve the required width. Multiple rolling passes refine the grain structure and enhance mechanical properties.

The strip is immersed in an acidic solution to remove surface scale and oxides. Pickling ensures a cleaner surface that is suitable for later cold rolling and finishing.

Cold rolling further reduces the thickness, improves flatness, and enhances the surface finish. This process ensures high precision and strength required for precision applications.

The strip undergoes annealing to restore ductility, polishing to improve surface brightness, and slitting/cutting to achieve the required width and length. The final product is a high-quality, corrosion-resistant stainless steel strip ready for industrial use.

Customized Alumina Ceramic Lined Project

Sort:99

High Chromium Alloy Lined Pipe

Sort:99