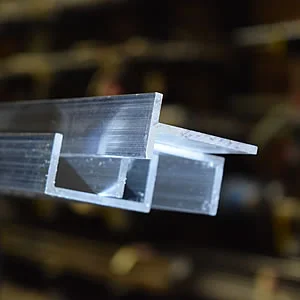

Durable Structural Tee Profiles

Versatile stainless steel tee section (t-profiles, t-bars) in 304/316l grades, metric sizes 25-500mm height/width per en 10088, with laser-fused custom options for structural support and corrosion resistance.

Durable Structural Tee Profiles

Versatile stainless steel tee section (t-profiles, t-bars) in 304/316l grades, metric sizes 25-500mm height/width per en 10088, with laser-fused custom options for structural support and corrosion resistance. ideal for german construction, architecture, and food processing—hygienic, machinable, and traceable for compliant, durable t-beams in frameworks and trims.

Stainless steel tee sections, also known as T-profiles, T-beams, or T-bars, are T-shaped structural profiles offering excellent strength and corrosion resistance. They are durable and versatile for structural and architectural applications, including frameworks, supports, bathroom and kitchen trims, cabinet edgings, frame working for glass facades and fascias in modern architecture.

Produced using laser fusion welding for customization, these tee bars ensure no production delays with value-engineered pricing and on-time delivery.

Our stainless steel sections are versatile, durable, and ideal for a variety of applications in construction, architecture, and general fabrication. Available in various shapes, such as angles, channels, beams, and hollow sections, these profiles provide excellent strength, corrosion resistance, and aesthetic appeal. Perfect for structural support, frameworks, and decorative elements, stainless steel sections ensure longevity and low maintenance, making them suitable for both indoor and outdoor projects. We offer a comprehensive range of sizes and grades to meet the specific requirements of your project.

Often referred to as T-profiles, T-beams or T-bars, stainless steel tee sections find use in numerous structural and architectural applications. Typical applications include bathroom and kitchen trims, cabinet edgings, frame working for glass facades and fascias and modern architecture. The corrosion resistance of the alloy is high, and the surface is straightforward to clean and sanitize. Our tee sections are aesthetically pleasing; it is possible to polish the material to an almost mirror finish. We offer tee sections in straight lengths which we also process in-house if required. Our stainless tee sections are easy to cut and provide good machinability.

Height/Width 25-500mm; Thickness 3mm+; Lengths 3-12m. Custom laser-fused options available.

| Height (mm) | Width (mm) | Thickness (mm) | Length (m) | Applications |

|---|---|---|---|---|

| 25-100 | 25-100 | 3-6 | 3-6 | Trims, small frameworks |

| 100-250 | 100-250 | 6-10 | 6-9 | Supports, architectural fascias |

| 250-500 | 250-500 | 10+ | 9-12 | Heavy structural T-beams |

With advanced laser-fused technology, stainless steel tee bars can be fully customized to meet precise application needs.

Popular stainless steel structural sections include beams, channels, and angles. However, stainless steel tee bars offer unique advantages for manufacturers and production lines. Product specifications include:

The most common stainless alloys used for tee bars are 304/304L and 316/316L, with duplex grades also increasing in demand. Laser fusion enables production in many other special alloys as well. Stainless tees are widely used in food processing and packaging—such as 2 × 2 × 1/4 tees for poultry conveyor lines. Custom designs, like tees with a 5° sloped flange for water runoff, are also feasible. Additional applications include equipment components, platforms, walkways, structural supports, and more.

Stainless steel T profiles (structural tees) are produced in limited standard sizes, but the flexibility of laser-fusion welding allows for many more custom options.

We supply standard grades such as 304/1.4301, 304L/1.4307, 316/1.4401, and 316L/1.4404. With high-precision laser welding technology, custom structural tees can be manufactured in any shape or alloy required to meet your exact performance specifications.

Perfect for hospital equipment, instrumentation and processing equipment for chemicals, dyes, crude and refined oils.

Great for chemical and pharmaceutical equipment, pump shafts and anything where you need a combination of low magnetic permeability and superior corrosion resistance.

Great for the film and photo industry, power station construction, automotive and general construction.

Customized Alumina Ceramic Lined Project

Sort:99

High Chromium Alloy Lined Pipe

Sort:99