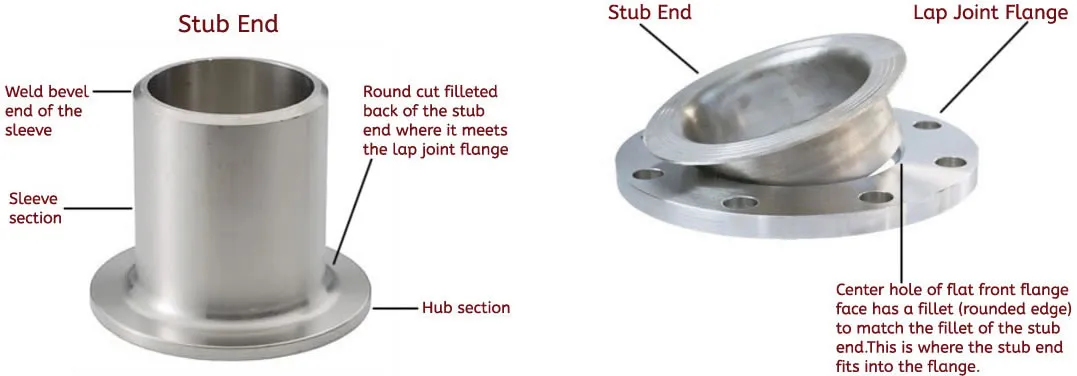

The a403 wps304l stainless stub end is a pipe fitting used in industrial piping systems, welded to a pipe and paired with a lap joint flange to form a flanged connection.

The a403 wps304l stainless stub end is a pipe fitting used in industrial piping systems, welded to a pipe and paired with a lap joint flange to form a flanged connection.

The A403 WPS304L Stainless Stub End is a pipe fitting used in industrial piping systems, welded to a pipe and paired with a lap joint flange to form a flanged connection. Compliant with ASTM A403 standards, this WPS304L stainless steel fitting offers superior pipeline corrosion protection and durability, making it ideal for boiler pipeline protection in industries such as chemical processing, food and pharmaceuticals, and marine applications as of 05:55 AM PDT, September 01, 2025. Its butt-weld design ensures strong, leak-proof connections, while the lap joint flange facilitates easy alignment and disassembly.

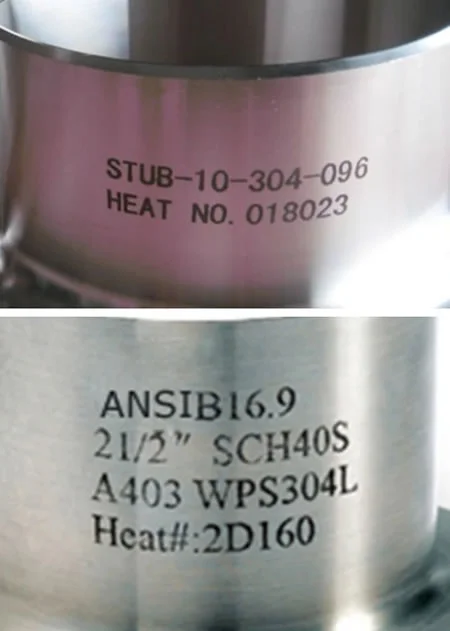

Manufactured using seamless or welded processes, the A403 WPS304L Stainless Stub End is made from low-carbon 304L stainless steel (WPS304L), which provides excellent corrosion resistance in acidic, saline, or high-humidity environments. Available in sizes from 1/2” to 48” (DN 15–DN 1200) and wall thicknesses such as SCH 10S, SCH 40S, or SCH 80S, it meets diverse industrial piping requirements. Rigorous testing, including tensile, hydrostatic, and non-destructive tests (radiography or ultrasonic), ensures compliance with ASME B16.9 and MSS SP-43 standards.

Engineered for pipeline corrosion protection, the WPS304L material inherently resists corrosion without additional coatings, though epoxy or passivation can enhance durability in extreme conditions. Its robust construction withstands chemical exposure and moderate temperatures (up to 425°C), ensuring reliability for boiler pipeline protection. The fitting is welded using methods like GTAW or GMAW with compatible fillers (e.g., ER308L), ensuring seamless integration with pipelines like ASTM A312 TP304L or TP316L.

Unlike carbon steel fittings like ASTM A234 WPB Stub End, Equal Tee, Reducing Tee, Lateral Tee, or low-alloy ASTM A234 WP22 Tee (as discussed in your previous queries), the A403 WPS304L Stainless Stub End is designed for flanged connections in corrosive environments, not branching. It enables cost savings by allowing lower-grade lap joint flanges (e.g., carbon steel) with high-grade stainless steel stub ends. Type A stub ends match lap joint flange profiles, Type B suits slip-on flanges, and Type C is flared for versatility. Its design supports applications requiring frequent disassembly, such as maintenance-heavy systems in food processing or chemical plants.

The A403 WPS304L Stainless Stub End addresses challenges like pipeline corrosion, connection reliability, and maintenance efficiency in corrosive industrial systems. Its durable stainless steel construction ensures long-term performance, safety, and cost-effectiveness, making it a top choice for engineers seeking robust industrial piping and boiler pipeline protection solutions.

| Element | Composition (%) |

|---|---|

| Carbon (C) | ≤0.03 |

| Manganese (Mn) | ≤2.00 |

| Phosphorus (P) | ≤0.045 |

| Sulfur (S) | ≤0.030 |

| Silicon (Si) | ≤1.00 |

| Chromium (Cr) | 18.0–20.0 |

| Nickel (Ni) | 8.0–12.0 |

| Property | Value |

|---|---|

| Tensile Strength, min (MPa) | 485 |

| Yield Strength, min (MPa) | 170 |

| Elongation, min (%) | 40 |

| Hardness, max (HBW) | 201 |

| Feature | A403 WPS304L Stub End | A234 WPB Stub End | A403 WPS304L Tee |

|---|---|---|---|

| Material Type | Stainless Steel (304L) | Carbon Steel | Stainless Steel (304L) |

| Temperature Range | Low to Moderate (up to 425°C) | Moderate (up to 650°C) | Low to Moderate (up to 425°C) |

| Corrosion Protection | Excellent (inherent) | Good (with coatings) | Excellent (inherent) |

| Pigging Compatibility | Poor (no bars) | Poor (no bars) | Poor (no bars) |

| Function | Flanged connection | Flanged connection | 90-degree branch |

| Applications | Chemical, Food, Marine, Boilers | Oil/Gas, Petrochemical, Boilers | Chemical, Food, Marine, Boilers |

| Tensile Strength (MPa) | 485 (min) | 415 (min) | 485 (min) |

| Yield Strength (MPa) | 170 (min) | 240 (min) | 170 (min) |

| Key Advantage | Superior corrosion resistance | Cost-effective flanged joints | Uniform pipe branching |

A403 WPS304L Stub End is widely used in chemical, food & beverage, water treatment, petrochemical, and pharmaceutical industries, ensuring leak-proof and reliable joints.

Quick removal of piping sections without disturbing the entire system for maintenance and inspection.

Use expensive materials only where needed, with cheaper backing flanges reducing overall cost.

Rotating backing flange allows easy alignment of bolt holes during installation.

Properly welded and assembled stub ends provide secure and leak-proof joints.

Compatible with various flange types and available in wide range of materials and sizes.

Manufactured to strict international standards with comprehensive testing and inspection.

Description: Produced and machined specifically to fit lap joint flanges.

Description: Suited for standard slip-on flanges acting as lap-joint flanges.

Description: Versatile for both lap joint and slip-on backing flanges.

Description: Similar to Type "C" with concentric serrations on lap face.

Longer length for easier alignment and welding. Suitable for frequent disassembly applications.

Standard Lap Joint FlangesSimilar length to pipe. Ideal for space-limited applications where flange needs to be close to pipe end.

Slip-On FlangesIn piping systems, a stub end is a crucial component used for connecting pipes of different materials and sizes. It provides a convenient and cost-effective solution for achieving a leak-free joint without the need for welding. In this article, we will explore the geometry, types, and applications of stub ends, shedding light on their significance in various industries and projects.

| N.D. | Out diameter | Hight(F) | Stub end O.D.(G) | Beveld radio(R) | ||||

|---|---|---|---|---|---|---|---|---|

| NPS | DN | OD | Mss | ANSI | Nominal&max | Nominal&min | A Max | B Max |

| 1/2 | 15 | 21.3 | 50.8 | 76.2 | 35 | 34 | 3 | 0.8 |

| 3/4 | 20 | 26.7 | 50.8 | 76.2 | 43 | 42 | 3 | 0.8 |

| 1 | 25 | 33.4 | 50.8 | 101.6 | 51 | 50 | 3 | 0.8 |

| 1 1/4 | 32 | 42.4 | 50.8 | 101.6 | 64 | 63 | 4.8 | 0.8 |

| 1 1/2 | 40 | 48.3 | 50.8 | 101.6 | 73 | 72 | 6.4 | 0.8 |

| 2 | 50 | 60.3 | 63.5 | 152.4 | 92 | 91 | 7.9 | 0.8 |

| 2 1/2 | 65 | 73 | 63.5 | 152.4 | 105 | 104 | 7.9 | 0.8 |

| 3 | 80 | 88.9 | 63.5 | 152.4 | 127 | 126 | 9.6 | 0.8 |

| 3 1/2 | 90 | 101.6 | 76.2 | 152.4 | 140 | 139 | 9.6 | 0.8 |

| 4 | 100 | 114.3 | 76.2 | 152.4 | 157 | 156 | 11.2 | 0.8 |

| 5 | 125 | 141.3 | 76.2 | 203.2 | 186 | 185 | 11.2 | 1.6 |

| 6 | 150 | 168.3 | 88.9 | 203.2 | 216 | 215 | 12.7 | 1.6 |

| 8 | 200 | 219.1 | 101.6 | 203.2 | 270 | 269 | 12.7 | 1.6 |

| 10 | 250 | 273.1 | 127 | 254 | 324 | 322 | 12.7 | 1.6 |

| 12 | 300 | 323.9 | 152.4 | 254 | 381 | 379 | 12.7 | 1.6 |

| 14 | 350 | 355.6 | 152.4 | 304.8 | 413 | 411 | 12.7 | 1.6 |

| 16 | 400 | 406.4 | 152.4 | 304.8 | 470 | 468 | 12.7 | 1.6 |

| 18 | 450 | 457.2 | 152.4 | 304.8 | 533 | 531 | 12.7 | 1.6 |

| 20 | 500 | 508 | 152.4 | 304.8 | 584 | 582 | 12.7 | 1.6 |

| 22 | 550 | 559 | 152.4 | 304.8 | 641 | 639 | 12.7 | 1.6 |

| 24 | 600 | 610 | 152.4 | 304.8 | 692 | 690 | 12.7 | 1.6 |

The following information shall be provided to order a stub end:

Stub ends can be ordered with different ends finishing:

There are hundreds of different grades of stainless steel on the market. Each formulation offers enhanced corrosion resistance over plain carbon steel. Grade 304, 304L, and 304H are chemically similar but vary in carbon content, impacting their strength and weldability.

The similarity in naming can lead to confusion, especially between 304 and 304L. Understanding their composition and application is key.

| Element | Grade | ||

|---|---|---|---|

| 304 | 304L | 304H | |

| Carbon (C) | 0.08 | 0.030 | 0.04 – 0.10 |

| Manganese (Mn) | 2.00 | 2.00 | 2.00 |

| Phosphorus (P) | 0.045 | 0.045 | 0.045 |

| Sulfur (S) | 0.030 | 0.030 | 0.030 |

| Silicon (Si) | 0.75 | 0.75 | 0.75 |

| Chromium (Cr) | 18.00 – 20.00 | 18.00 – 20.00 | 18.00 – 20.00 |

| Nickel (Ni) | 8.00 – 10.50 | 8.00 – 12.00 | 8.00 – 10.50 |

| Nitrogen (N) | 0.10 | 0.10 | 0.10 |

| Grade | Tensile Strength (N/mm²) | Yield Strength (0.2%, N/mm²) | Elongation (%) |

|---|---|---|---|

| 304 Annealed | 500–700 | 195 | 40 |

| 304L Annealed | 460–680 | 180 | 40 |

| Property | Metric | Imperial |

|---|---|---|

| Density | 8 g/cm³ | 0.289 lb/in³ |

| Property | Metric | Imperial | Notes |

|---|---|---|---|

| Hardness, Brinell | 123 | 123 | Converted from Rockwell B |

| Hardness, Knoop | 138 | 138 | Converted from Rockwell B |

| Hardness, Rockwell B | 70 | 70 | |

| Hardness, Vickers | 129 | 129 | Converted from Rockwell B |

| Tensile Strength, Ultimate | 505 MPa | 73,200 psi | |

| Tensile Strength, Yield | 215 MPa | 31,200 psi | 0.2% offset |

| Elongation at Break | 70% | 70% | in 50 mm |

| Modulus of Elasticity | 193 – 200 GPa | 28,000 – 29,000 ksi | |

| Poisson’s Ratio | 0.29 | 0.29 | |

| Charpy Impact | 325 J | 240 ft-lb | |

| Shear Modulus | 86 GPa | 12,500 ksi |

| Property | Value (Metric) | Value (Imperial) | Condition |

|---|---|---|---|

| Electrical Resistivity | 7.2 × 10⁻⁵ Ω·cm | 7.2 × 10⁻⁵ Ω·cm | At 20°C; increases at 650°C |

| Magnetic Permeability | 1.008 | 1.008 | At room temperature |

We stock stainless steels in a multitude of shapes and sizes.

We support our stainless steel stock with a wide range of shapes and sizes to suit your engineering applications. We hold thirteen different types of shapes to support the grades of material we stock, including bars, sheets and plates.

Stainless Carbon Steel Composite Pipe

Sort:99

Material-Specific Erosion Shields

Sort:99

The A403 WPS304L Stainless Stub End allows sections pipe to be opened for inspection, cleaning or replacement without the need for additional welding.

Sort:0

Customized Alumina Ceramic Lined Project

Sort:99

High Chromium Alloy Lined Pipe

Sort:99

Sort:0