- 304/316 Buttweld, Socket Weld & Threaded

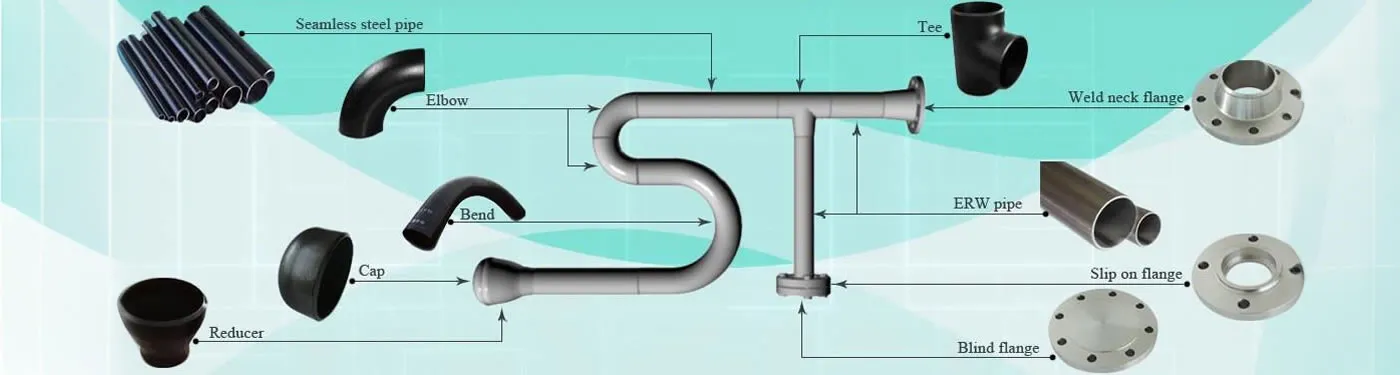

Full range of stainless steel pipe fittings: 304/316/316l buttweld elbows, tees, reducers, caps; socket weld and threaded fittings; seamless & welded. asme b16.9, b16.11, mss sp-43. stock + custom fabrication for oil & gas, food, pharma, and marine.

| Grade | C (% max) | Mn (% max) | Si (% max) | P (% max) | S (% max) | Cr (%) | Ni (%) | Mo (%) | N (% max) |

|---|---|---|---|---|---|---|---|---|---|

| 304 | 0.08 | 2.00 | 1.00 | 0.045 | 0.030 | 18.0-20.0 | 8.0-11.0 | - | 0.10 |

| 304L | 0.03 | 2.00 | 1.00 | 0.045 | 0.030 | 18.0-20.0 | 8.0-12.0 | - | 0.10 |

| 316 | 0.08 | 2.00 | 1.00 | 0.045 | 0.030 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 | 0.10 |

| 316L | 0.03 | 2.00 | 1.00 | 0.045 | 0.030 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 | 0.10 |

The low carbon content in 304L and 316L enhances weldability, while molybdenum in 316 and 316L improves resistance to pitting and crevice corrosion, making Stainless Steel Pipe Fittings ideal for harsh environments.

| Grade | Tensile Strength (min, MPa) | Yield Strength (min, MPa) | Elongation (min, %) | Hardness (max, HB) | Hardness (max, HRB) |

|---|---|---|---|---|---|

| 304 | 515 | 205 | 40 | 201 | 92 |

| 304L | 485 | 170 | 40 | 201 | 92 |

| 316 | 515 | 205 | 40 | 217 | 95 |

| 316L | 485 | 170 | 40 | 217 | 95 |

These mechanical properties make Stainless Steel Pipe Fittings suitable for applications requiring high strength and corrosion resistance, such as architectural structures, marine environments, and chemical processing.

In order to solve the cumbersome and difficult to remember stainless steel grades, improve the practicability of the brand representation, and the contrast with the international standard grades, China has formulated the "Universal Code System for Steel and Alloy Grades", such as 06Cr19Ni10, corresponding to 304. Different grades of stainless steel have different ingredients, but they all have a national standard. The standards of each country are also different.

| No | China (GB) | Japan (JIS) | American | Korea (KS) | EU (BS EN) | India (IS) | Australia (AS) | Taiwan (CNS) | ||

|---|---|---|---|---|---|---|---|---|---|---|

| Old | New (07.10) | SUS | ASTM | UNS | STS | EN | IS | AS | CNS | |

| Austenitic Stainless Steel | ||||||||||

| 1 | 1Cr17Mn6Ni5N | 12Cr17Mn6Ni5N | SUS201 | 201 | S20100 | STS201 | 1.4372 | 10Cr17Mn6Ni4N20 | 201-2 | 201 |

| 2 | 1Cr18Mn8Ni5N | 12Cr18Mn9Ni5N | SUS202 | 202 | S20200 | STS202 | 1.4373 | — | — | 202 |

| 3 | 1Cr17Ni7 | 12Cr17Ni7 | SUS301 | 301 | S30100 | STS301 | 1.4319 | 10Cr17Ni7 | 301 | 301 |

| 4 | 0Cr18Ni9 | 06Cr19Ni10 | SUS304 | 304 | S30400 | STS304 | 1.4301 | 07Cr18Ni9 | 304 | 304 |

| 5 | 00Cr19Ni10 | 022Cr19Ni10 | SUS304L | 304L | S30403 | STS304L | 1.4306 | 02Cr18Ni11 | 304L | 304L |

| 6 | 0Cr19Ni9N | 06Cr19Ni10N | SUS304N1 | 304N | S30451 | STS304N1 | 1.4315 | — | 304N1 | 304N1 |

| 7 | 0Cr19Ni10NbN | 06Cr19Ni9NbN | SUS304N2 | XM21 | S30452 | STS304N2 | — | — | 304N2 | 304N2 |

| 8 | 00Cr18Ni10N | 022Cr19Ni10N | SUS304LN | 304LN | S30453 | STS304LN | — | — | 304LN | 304LN |

| 9 | 1Cr18Ni12 | 10Cr18Ni12 | SUS305 | 305 | S30500 | STS305 | 1.4303 | — | 305 | 305 |

| 10 | 0Cr23Ni13 | 06Cr23Ni13 | SUS309S | 309S | S30908 | STS309S | 1.4833 | — | 309S | 309S |

| 11 | 0Cr25Ni20 | 06Cr25Ni20 | SUS310S | 310S | S31008 | STS310S | 1.4845 | — | 310S | 310S |

| 12 | 0Cr17Ni12Mo2 | 06Cr17Ni12Mo2 | SUS316 | 316 | S31600 | STS316 | 1.4401 | 04Cr17Ni12Mo2 | 316 | 316 |

| 13 | 0Cr18Ni12Mo3Ti | 06Cr17Ni12Mo2Ti | SUS316Ti | 316Ti | S31635 | — | 1.4571 | 04Cr17Ni12MoTi20 | 316Ti | 316Ti |

| 14 | 00Cr17Ni14Mo2 | 022Cr17Ni12Mo2 | SUS316L | 316L | S31603 | STS316L | 1.4404 | 02Cr17Ni12Mo2 | 316L | 316L |

| 15 | 0Cr17Ni12Mo2N | 06Cr17Ni12Mo2N | SUS316N | 316N | S31651 | STS316N | — | — | 316N | 316N |

| 16 | 00Cr17Ni13Mo2N | 022Cr17Ni13Mo2N | SUS316LN | 316LN | S31653 | STS316LN | 1.4429 | — | 316LN | 316LN |

| 17 | 0Cr18Ni12Mo2Cu2 | 06Cr18Ni12Mo2Cu2 | SUS316J1 | — | — | STS316J1 | — | — | 316J1 | 316J1 |

| 18 | 00Cr18Ni14Mo2Cu2 | 022Cr18Ni14Mo2Cu2 | SUS316J1L | — | — | STS316J1L | — | — | — | 316J1L |

| 19 | 0Cr19Ni13Mo3 | 06Cr19Ni13Mo3 | SUS317 | 317 | S31700 | STS317 | — | — | 317 | 317 |

| 20 | 00Cr19Ni13Mo3 | 022Cr19Ni13Mo3 | SUS317L | 317L | S31703 | STS317L | 1.4438 | — | 317L | 317L |

| 21 | 0Cr18Ni10Ti | 06Cr18Ni11Ti | SUS321 | 321 | S32100 | STS321 | 1.4541 | 04Cr18Ni10Ti20 | 321 | 321 |

| 22 | 0Cr18Ni11Nb | 06Cr18Ni11Nb | SUS347 | 347 | S34700 | STS347 | 1.4550 | 04Cr18Ni10Nb40 | 347 | 347 |

| Austenitic-Ferritic Stainless Steel (Duplex) | ||||||||||

| 23 | 0Cr26Ni5Mo2 | — | SUS329J1 | 329 | S32900 | STS329J1 | 1.4477 | — | 329J1 | 329J1 |

| 24 | 00Cr18Ni5Mo3Si2 | 022Cr19Ni5Mo3Si2N | SUS329J3L | — | S31803 | STS329J3L | 1.4462 | — | 329J3L | 329J3L |

| Ferritic Stainless Steel | ||||||||||

| 25 | 0Cr13Al | 06Cr13Al | SUS405 | 405 | S40500 | STS405 | 1.4002 | 04Cr13 | 405 | 405 |

| 26 | — | 022Cr11Ti | SUH409 | 409 | S40900 | STS409 | 1.4512 | — | 409L | 409L |

| 27 | 00Cr12 | 022Cr12 | SUS410L | — | — | STS410L | — | — | 410L | 410L |

| 28 | 1Cr17 | 10Cr17 | SUS430 | 430 | S43000 | STS430 | 1.4016 | 05Cr17 | 430 | 430 |

| 29 | 1Cr17Mo | 10Cr17Mo | SUS434 | 434 | S43400 | STS434 | 1.4113 | — | 434 | 434 |

| 30 | — | 022Cr18NbTi | — | — | S43940 | — | 1.4509 | — | 439 | 439 |

| 31 | 00Cr18Mo2 | 019Cr19Mo2NbTi | SUS444 | 444 | S44400 | STS444 | 1.4521 | — | 444 | 444 |

| Martensitic Stainless Steel | ||||||||||

| 32 | 1Cr12 | 12Cr12 | SUS403 | 403 | S40300 | STS403 | — | — | 403 | 403 |

| 33 | 1Cr13 | 12Cr13 | SUS410 | 410 | S41000 | STS410 | 1.4006 | 12Cr13 | 410 | 410 |

| 34 | 2Cr13 | 20Cr13 | SUS420J1 | 420 | S42000 | STS420J1 | 1.4021 | 20Cr13 | 420 | 420J1 |

| 35 | 3Cr13 | 30Cr13 | SUS420J2 | — | — | STS420J2 | 1.4028 | 30Cr13 | 420J2 | 420J2 |

| 36 | 7Cr17 | 68Cr17 | SUS440A | 440A | S44002 | STS440A | — | — | 440A | 440A |

Pipe fitting dimensions are in either metric or Standard English. Common fittings include 90° long radius, 45° elbows, and 180° return bends. LR and SR elbows are widely used in heating and cooling units.

Define requirements for design, fabrication, materials, tests, and inspection of piping systems.

Provide design and construction rules for pipe fittings, adapters, flanges, sleeves, elbows, tees, valves, etc.

| Carbon Steel | A234 WPB (A & C available) |

| High Yield Carbon | Enhanced strength properties |

| Stainless Steel | 304, 316 (SCH 10 common) |

| Nickel Alloys | Specialized applications |

| ASME B16.9 | Factory-Made Wrought Steel |

| ASME B16.28 | Short Radius Elbows |

| ASME B16.25 | Buttwelding Ends |

| MSS SP-97 | Welding End Standards |

Plain Bevel and Compound Bevel

All welded pipe fittings have beveled ends to allow for ease of welding. This bevel allows for full penetration weld in most cases.

Welding Bevel acc. to

Butt weld pipe fitting bevels provide reliable, high-strength connections for demanding industrial piping applications.

|

DIN Standard German Industrial Standard |

EN Standard European Norm (CEN) |

ASME Standard American Society of Mechanical Engineers |

|---|---|---|

Low-Carbon & Low-Temp Steel

|

Low-Carbon & Low-Temp Steel

|

Low-Carbon & Low-Temp Steel

|

Low-Alloy High-Strength Steel

|

Low-Alloy High-Strength Steel

|

Low-Alloy High-Strength Steel

|

Molybdenum Steel (High-Temp)

|

Molybdenum Steel (High-Temp)

|

Molybdenum Steel (High-Temp)

|

Cr-Mo Steel (Medium Cr Content)

|

Cr-Mo Steel (Medium Cr Content)

|

Cr-Mo Steel (Medium Cr Content)

|

High Cr-Mo-V Steel (Super High-Temp)

|

High Cr-Mo-V Steel (Super High-Temp)

|

High Cr-Mo-V Steel (Super High-Temp)

|

ASTM A210 Grade C Pipe Bending

Sort:0

Rare Earth Alloy Wear Resistant Pipe Bending

Sort:0

Silicon Carbide Alloy Ceramic Elbow

Sort:0

Sort:0

ASTM A403 WP304 Stainless Steel Pipe Elbow

Sort:0

Rare Earth Alloy Wear Resistant Backpack Elbow

Sort:0

Industries Using

Stainless Steel Pipe Fittings components that are used to connect, join, or adapt different parts of a system, such as pipes, tubes, or hoses. They serve multiple purposes, including:

The choice of fittings depends on the specific requirements of the system, including factors like the type of fluid or gas, pressure, temperature, and the layout of the piping or tubing system.

Customized Alumina Ceramic Lined Project

Sort:99

High Chromium Alloy Lined Pipe

Sort:99

Sort:0

Wear-Resistant Hardfacing Liner Plate

Sort:0