- Precision Flow Control & Regulation

Globe valves provide excellent throttling capability and precise flow control, making them ideal for applications requiring flow regulation, pressure control, and tight sealing in high-pressure and high-temperature systems.

Versatile linear-motion valves engineered for precise flow regulation and reliable shutoff in high-pressure pipeline applications.

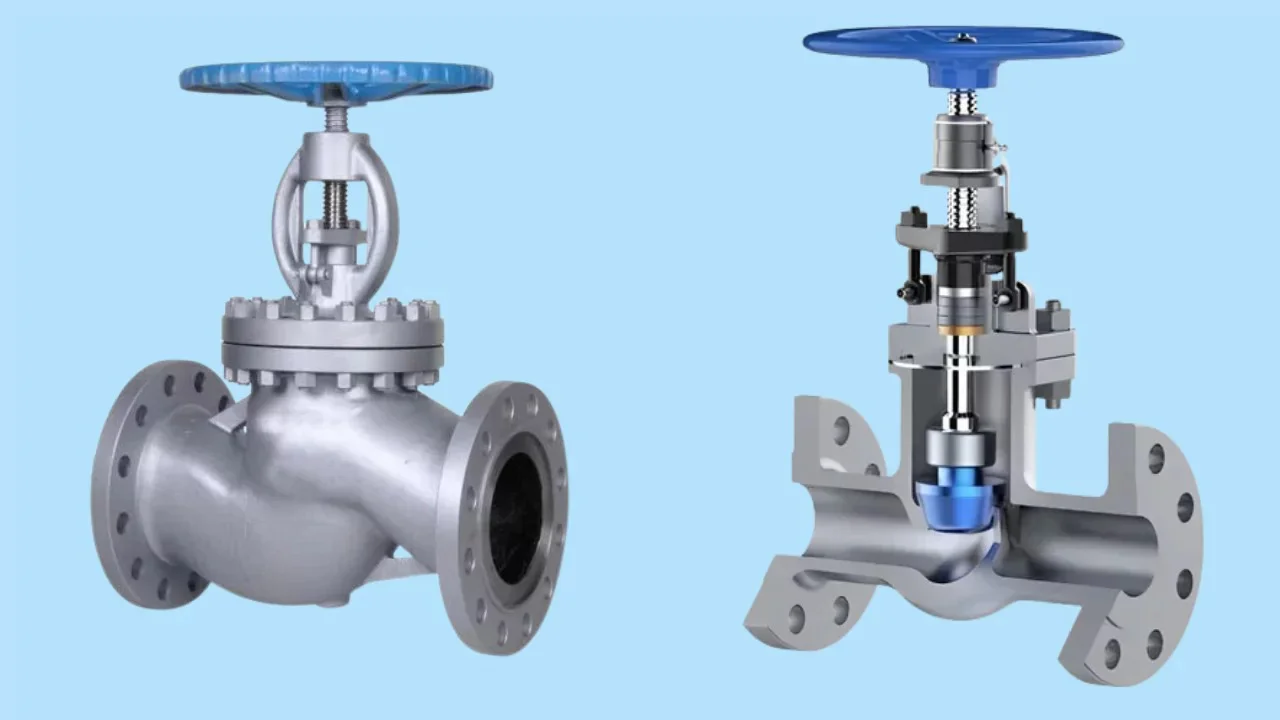

A globe valve is a type of stop valve used for regulating flow in a pipeline, consisting of a movable plug or disc element and a stationary ring seat in a generally spherical body. Unlike gate valves, globe valves excel at flow regulation and throttling control.

Excellent throttling capability allows precise control of flow rate and pressure.

Spherical body design with disc provides superior sealing and minimal leakage.

Disc moves parallel to flow direction for precise control and positive shutoff.

The Globe Valve is a versatile linear-motion valve engineered for precise flow regulation and reliable shutoff in high-pressure pipeline applications, ideal for oil, gas, water, and chemical systems. Designed to API 602, ASME B16.34, and BS 1873 standards, this Industrial Globe Valve features a spherical body and disc-plug mechanism, providing superior throttling capabilities and tight sealing for pressures up to PN40 (Class 150-600) and temperatures to 425°C. Constructed from forged ASTM A216 WCB carbon steel or A351 CF8M stainless steel, it ensures excellent corrosion resistance with coatings like epoxy or 3LPE, making it suitable for refineries, petrochemical plants, and power generation facilities.

Precision-manufactured through forging or casting, the Pipeline Flow Control Valve undergoes stringent heat treatment and 100% non-destructive testing (RT, UT, MT, PT) to ensure structural integrity. Available in sizes from 1/2" to 24" (DN15 to DN600) with flanged, threaded, or butt-weld ends per ASME B16.5/B16.25, it supports manual handwheel or actuated operation with an outside screw and yoke (OS&Y) rising stem for clear position indication. The disc-plug, often hard-faced with Stellite #6, ensures abrasion resistance and bidirectional sealing, achieving Class VI shutoff per API 598. Hydrostatic shell tests at 1.5x rated pressure confirm tensile strengths above 485 MPa, ensuring durability under cyclic loading.

The Corrosion Resistant Globe Valve excels in throttling applications, offering precise flow control with minimal cavitation compared to gate or ball valves. Its globe-shaped body increases flow resistance for better regulation, ideal for steam, condensate, or viscous media. Enhanced with NACE MR0175 compliance for sour service, it resists H2S and chlorides in aggressive environments like offshore platforms. Optional features like bellows seals or pressure-seal bonnets enhance safety in high-temperature or hazardous applications. Face-to-face dimensions align with ASME B16.10 and BS EN 558 for seamless integration.

Compared to gate valves, the High Pressure Globe Valve provides superior flow modulation but higher pressure drop, making it ideal for applications requiring frequent adjustments rather than full-bore isolation. It outperforms ball valves in throttling precision, with 3-5 times longer service life in high-pressure, corrosive environments due to its robust disc and seat design. Customizable with pneumatic or electric actuators for automation, it suits remote operations in water treatment or chemical processing. Compliance with API 6FA for fire safety and SIL 3 for critical systems ensures reliability in demanding conditions.

Addressing challenges like pipeline corrosion, cavitation in throttling, and leakage under high pressures, the Globe Valve incorporates secondary seals and low-emission packing for enhanced safety. Its value-engineered design balances performance and cost, reducing maintenance in long-term projects. Whether regulating flow in steam boilers or isolating chemical lines, the Globe Valve delivers precise, reliable Pipeline Flow Control Valve solutions for global industrial needs.

Typical specifications for key materials in the Globe Valve, focusing on ASTM A216 WCB Carbon Steel for the body, ASTM A351 CF8M Stainless Steel for trim, and Stellite #6 for hard-facing.

| Material | Chemical Composition (%) | Mechanical Properties |

|---|---|---|

| ASTM A216 WCB Carbon Steel - Body |

|

|

| ASTM A351 CF8M Stainless Steel - Trim/Disc |

|

|

| Stellite #6 - Hard-Facing Overlay |

|

|

Engineered for precise flow control and reliable isolation with corrosion-resistant design.

Globe valves manage water flow in a pipeline through a movable plug/disc-type element and a stationary ring seat in a spherical body. The plug is connected to a stem that operates through a screw action.

Here is a quick-reference globe valve diagram for easy understanding:

There are three basic globe valve body designs: Tee, Angle, and Wye. Each design has unique characteristics, advantages, and applications.

Primarily, when people talk about the type of globe valve, they mean the body style.

The classic and most common globe valve design. The seat is placed horizontally, and the stem moves vertically to the flow.

The ends are set at a 90° angle, requiring fluid to make a single turn. Useful for flows that pulse or surge.

The seat and stem are set at a 45° angle, providing a straighter flow path and reducing pressure drop.

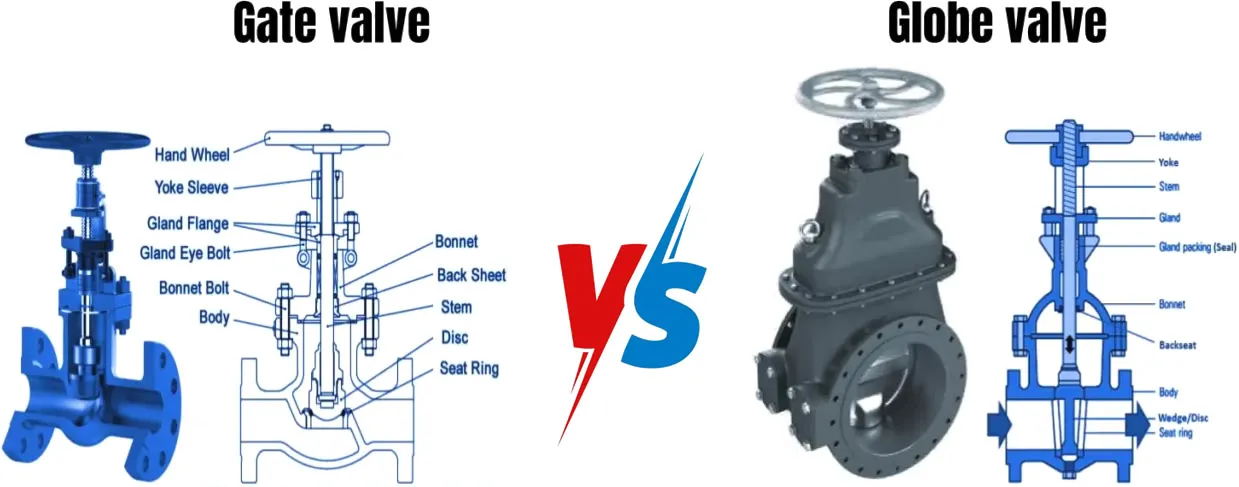

Globe valves and Gate valves are among the most common valves used in industrial plants. Both are engineered to keep systems running efficiently and safely, but their unique designs make them suitable for different applications.

| Aspect | Globe Valve | Gate Valve |

|---|---|---|

| Design | Parts are located inside the cavity, with a rising stem that allows flow changes but also contributes to higher pressure drop. | Simpler construction, most internal components are in the upper part of the body. Provides little pressure drop when open. |

| Flow Control | Excellent for throttling and regulating flow. | Designed mainly for on/off service, not ideal for throttling. |

| Pressure Drop | Higher pressure drop due to changes in flow direction. | Low pressure drop when fully open, straight-through flow path. |

| Applications | Used in applications requiring frequent operation and precise flow control. | Common in pipelines for isolation service, where the valve is fully open or closed. |

| Operation Speed | Slower operation due to shorter stem travel. | Faster operation with longer stem travel to open/close fully. |

| Durability | Better suited for throttling but may wear faster under high-pressure drops. | Longer service life when used in fully open or closed positions. |

| Functions | Primarily used as a control valve. | Designed for media isolation, not for flow control. |

| Working | The disc moves parallel to media flow, requiring minimal lift for full flow. | The disc moves at a right angle to the flow, providing either full flow or zero flow. |

Comprehensive list of key international valve standards from major organizations, updated as of 2025.

| Organization | Standard | Description |

|---|---|---|

| ANSI | American National Standards Institute | General industrial standards |

| API | American Petroleum Institute | Standards for oil and gas industry |

| ASME | American Society of Mechanical Engineers | Boiler and pressure vessel codes |

| BS | British Standards | UK national standards |

| GB, JB, HG | China Valve Standards | Chinese national and industry standards |

| FCI | Fluid Control Institute | Standards for fluid control and conditioning equipment |

American National Standards Institute

| Code | ANSI Standard Name |

|---|---|

| ANSI A126 | Grey Iron Castings for Valves, Flanges, and Pipe Fittings |

| ANSI A181 | Forged or Rolled Steel Pipe Flanges, Forged Fittings, and Valves and Parts for General Service |

| ANSI B16.10 | Face-to-Face and End-to-End Dimensions of Valves |

| ANSI B16.34 | Valves - Flanged, Threaded, and Welding End |

| ANSI B16.5 | Pipe Flanges and Flanged Fittings |

| ANSI/FCI 70-2 | Control Valve Seat Leakage |

| ANSI B127.1 | Constant-Level Oilers |

American Petroleum Institute

| Code | API Standard Name |

|---|---|

| API 526 | Flanged Steel Pressure-Relief Valves |

| API 527 | Seat Tightness of Pressure Relief Valves |

| API 594 | Check Valves: Flanged, Lug, Bolted Bonnet |

| API 595 | Cast Iron Gate Valves - Flanged Bonnet |

| API 597 | Steel Venturi Gate Valves - Flanged and Welding Ends |

| API 598 | Valve Inspection and Testing |

| API 599 | Steel and Ductile Iron Plug Valves |

| API 600 | Bolted Bonnet Steel Gate Valves for Refinery Service |

| API 602 | Compact Steel Gate Valves - Flanged, Threaded, and Welding Ends |

| API 603 | Corrosion-Resistant Gate Valves - Flanged Ends |

| API 604 | Ductile Iron Gate Valves - Flanged Ends |

| API 607 | Fire Test for Quarter-Turn Valves |

| API 608 | Metal Ball Valves - Flanged, Threaded, and Welding Ends |

| API 609 | Butterfly Valves: Double Flanged, Lug- and Wafer-Type |

| API 6D | Pipeline and Piping Valves |

| API 6FA | Fire Test for Valves |

| API RP 574 | Inspection Practices for Piping System Components |

| API RP 576 | Inspection of Pressure-Relieving Devices |

American Society of Mechanical Engineers

| Code | ASME Standard Name |

|---|---|

| ASME A105/A105M | Carbon Steel Forgings for Piping Applications |

| ASME A181/A181M | Carbon Steel Forgings, for General-Purpose Pipes |

| ASME A182/A182M | Forged or Rolled Alloy and Stainless Steel Pipe Flanges, Forged Fittings, and Valves and Parts for High-Temperature Service |

| ASME A350/A350M | Carbon and Low-Alloy Steel Forgings for Low-Temperature Service |

| ASME A694/A694M | Carbon and Alloy Steel Forgings for Pipe Flanges, Fittings, Valves, and Parts for High-Pressure Transmission Service |

| ASME B16.5 | Pipe Flanges and Flanged Fittings: NPS 1/2 Through NPS 24 Metric/Inch Standard |

| ASME B16.10 | Face-to-Face and End-to-End Dimensions of Valves |

| ASME B16.11 | Forged Fittings, Socket-Welding and Threaded |

| ASME B16.34 | Valves - Flanged, Threaded, and Welding End |

| ASME B31.1 | Power Piping |

| ASME B31.3 | Process Piping |

| ASME F1508 | Standard Specification for Angle Style, Pressure Relief Valves for Steam, Gas, and Liquid Services |

| ASME F1565 | Pressure-Reducing Valves for Steam Service |

British Standards Institution

| Code | British Standard Name |

|---|---|

| BS 1212 | Float Operated Valves - Automatic Valves (Including Float Valves) for Tanks, Cisterns, Hot-Water Cylinders and Feed Cisterns |

| BS 1414 | Specification for Steel Wedge Gate Valves (Flanged and Butt-Welding Ends) for the Petroleum, Petrochemical and Allied Industries |

| BS 1552 | Specification for Control Plug Cocks for Low Pressure Gases |

| BS 1868 | Specification for Steel Check Valves (Flanged and Butt-Welding Ends) for the Petroleum, Petrochemical and Allied Industries |

| BS 1873 | Specification for Steel Globe and Globe Stop and Check Valves (Flanged and Butt-Welding Ends) for the Petroleum, Petrochemical and Allied Industries |

| BS 1952 | Specification for Copper Alloy Gate Valves for General Purposes |

| BS 2080 | Specification for Face-to-Face, Centre-to-Face, End-to-End and Centre-to-End Dimensions for Flanged and Butt-Welding End Steel Valves for the Petroleum, Petrochemical and Allied Industries |

| BS 2995 | Specification for Cast and Forged Steel Wedge Gate, Globe, Check and Plug Valves Screwed and Socket-Welding Sizes 1/2 in and Smaller for the Petroleum Industry |

| BS 3464 | Specification for Cast Iron Gate Valves for General Purposes |

| BS 5150 | Specification for Cast Iron Wedge and Double Disk Gate Valves for General Purposes |

| BS 5151 | Specification for Cast Iron Gate (Parallel Slide) Valves for General Purposes |

| BS 5152 | Specification for Cast Iron Globe and Globe Stop and Check Valves for General Purposes |

| BS 5153 | Specification for Cast Iron Check Valves for General Purposes |

| BS 5154 | Specification for Copper Alloy Globe, Globe Stop and Check, Check and Gate Valves for General Purposes |

| BS 5155 | Specification for Butterfly Valves for General Purposes |

| BS 5156 | Specification for Screw-Down Diaphragm Valves for General Purposes |

| BS 5157 | Specification for Steel Gate (Parallel Slide) Valves for General Purposes |

| BS 5159 | Specification for Cast Iron and Carbon Steel Ball Valves for General Purposes |

| BS 5160 | Specification for Steel Globe Valves, Globe Stop Valves, Stop and Check Valves and Lift Type Check Valves |

| BS 5351 | Specification for Steel Ball Valves for Petroleum, Petrochemical and Allied Industries |

| BS EN 12266-1 | Industrial Valves - Testing of Metallic Valves Part 1: Pressure Tests - Test Procedures |

China National Standards

| Code | GB Standard Name | Adopting Standard |

|---|---|---|

| GB 12220 | General Valve - Marking | ISO 5209 |

| GB 12221 | Flanged Ends Metal Valve - Face-to-Face Dimensions | ISO 5752 |

| GB 12222 | Multi-Turn Valve - The Connection of the Driving Device | ISO 5210/1-3 |

| GB 12223 | Part-Turn Valve - The Connection of the Driving Device | ISO 5211/1-3 |

| GB 12224 | Steel Valve - General Requirements | ANSI B16.34 |

| GB 12225 | General Valve - Copper Alloy Casting Ware Technology Requirements | ASTM B584 |

| GB 12226 | General Valve - Gray Cast Iron Technology Requirements | ISO 185, BS 1452 |

| GB 12228 | General Valve - Carbon Forging Steel Technology Requirements | ASTM A105, A181 |

| GB 12229 | General Valve - Carbon Casting Steel Technology Requirements | ASTM A703 |

| GB 12230 | General Valve - Austenitic Casting Steel Technology Requirements | ASTM A351 |

| GB 12232 | General Valve - Flanged Ends Iron Gate Valve | ISO 5996-1982, API 595 |

| GB 12233 | General Valve - Iron Gate Valve and Lift Check Valve | BS 5152, 5153 |

| GB 12234 | General Valve - Flanged and Butt-Welding Ends Copper Gate Valve | API 600 |

| GB 12237 | General Valve - Flanged and Butt-Welding Ends Steel Ball Valve | ISO 7121, API 607 |

| GB 12238 | General Valve - Flanged and Wafer Ends Butterfly Valve | BS 5155 |

| GB 12239 | General Valve - Diaphragm Valve | BS 5156, NFE 29 |

| GB 12240 | General Valve - Iron Plug Valve | API 593 |

| GB 12241 | Safety Valve - General Requirements | ISO 4126 |

| GB 12242 | Safety Valve - Characteristic Testing Solution | ANSI/ASME PTC 25.3 |

| GB 12243 | Direct Spring-Loaded Safety Valve | JIS B 8210 |

| GB 12244 | Pressure Reducing Valve - General Requirements | JIS B 8372, B8410 |

| GB 12245 | Pressure Reducing Valve - Characteristic Testing Solution | JIS B 8372, B8410 |

| GB 12246 | Pilot Operated Pressure Reducing Valve | JIS B 8372, DSS 405 |

| GB 12247 | Steam Trap Valve - Classification | ISO 6704 |

| GB 12248 | Steam Trap Valve - Technology Terms | ISO 6552 |

| GB 12249 | Steam Trap Valve - Marking | ISO 6553 |

| GB 12250 | Steam Trap Valve - Face-to-Face Dimensions | ISO 6554 |

| GB 12251 | Steam Trap Valve - Testing Solution | ISO 6948, 7841, 7842 |

| GB/T 13927 | General Valve - Pressure Testing | ISO 5208 |

| JB/T 6899-93 | Valve Fire-Proof Test | ISO 10497 |

| JB/T 7927-95 | Valve Casting Steelware Out-Form Quality Requirements | MSS SP-55 |

| ZBJ 16006-90 | Inspection and Testing of Valve | API 598 |

| Code | GB Standard Name |

|---|---|

| GB 12227 | General Valve - Ductile Cast Iron Technology Requirements |

| GB 12235 | General Valve - Flanged Steel Stop and Lift Check Valve |

| GB 12236 | General Valve - Steel Swing Check Valve |

| GB/T 13932 | General Valve - Iron Swing Check Valve |

| GB/T 15185 | Iron and Copper Ball Valve |

| GB/T 15188.1 | Valve Face-to-Face Dimensions - Butt-Welding Ends Valve |

| GB/T 15188.2 | Valve Face-to-Face Dimensions - Wafer Ends Valve |

| GB/T 15188.3 | Valve Face-to-Face Dimensions - Female Screw-Down Valve |

| GB/T 15188.4 | Valve Face-to-Face Dimensions - Male Screw-Down Valve |

| JB 93 | Handle |

| JB/T 450 | PN16-32.0 MPa Forging Angle Type High-Pressure Valve, Fastener, and Technology Requirements |

| JB/T 7745-95 | Pipeline Ball Valve |

| JB/T 8527-97 | Metal Sealing Butterfly Valve |

| JB/T 8473-96 | Instrument Valve Series |

| ZBJ 16004-88 | Reducing Valve Type and Basing Coefficient |

| ZBJ 16007-90 | Steam Trap Valve Technology Terms |

| ZBJ 16009-90 | Valve Pneumatic Actuator Technology Terms |

Standards for fluid control and conditioning equipment

The Fluid Control Institute (FCI) provides standards to assist in understanding and using control valves, solenoid valves, and regulators.

| Code | FCI Standard Name |

|---|---|

| ANSI/FCI 70-2 | Control Valve Seat Leakage |

| ANSI/FCI 70-3 | Control Valve Aerodynamic Noise Prediction |

| ANSI/FCI 91-1 | Qualification of Control Valve Stem Seals |

| ANSI/FCI 85-1 | Method of Determining the Thermal Expansion of a Filled Thermal System |

| FCI 68-2 | Procedure in Rating Flow and Pressure Characteristics of Solenoid Valves for Liquid Service |

| FCI 75-1 | Test Conditions and Procedures for Measuring Electrical Characteristics of Solenoid Valves |

| FCI 82-1 | Recommended Methods for Testing and Classifying the Water Hammer Characteristics of Electrically Operated Valves |

| ANSI/FCI 69-1 | Pressure Ratings of Traps |

Upstream, midstream, and downstream operations, including drilling, refining, and transportation.

Handling corrosive and hazardous chemicals in various chemical plants.

Steam, water, and fuel systems in thermal, nuclear, and hydroelectric plants.

Municipal water supply, wastewater treatment, and industrial water management.

Heating, ventilation, and air conditioning systems in commercial and industrial buildings.

Sterile and hygienic applications, precise flow control in sensitive industries.

Customized Alumina Ceramic Lined Project

Sort:99

High Chromium Alloy Lined Pipe

Sort:99

Sort:0