Heat-resistant Alloy Steel Shields For Industrial Boilers

1cr13 boiler tube shields protect boiler tubes from erosion and corrosion in high-temperature environments.

Heat-resistant Alloy Steel Shields For Industrial Boilers

1cr13 boiler tube shields protect boiler tubes from erosion and corrosion in high-temperature environments. made from heat-resistant alloy steel, these durable shields extend tube life in power plants and industrial systems.

1Cr13 boiler tube shields are protective components designed to safeguard boiler tubes from erosion, corrosion, and mechanical wear in high-temperature industrial environments. Made from 1Cr13 stainless steel (AISI 410 / X12Cr13), a martensitic stainless alloy with 11.5–13.5% chromium and 0.08–0.15% carbon, these shields offer high strength, excellent hardenability, and moderate corrosion resistance.

These erosion-resistant shields are widely used in power generation, petrochemical plants, refineries, and chemical processing industries, where boiler tubes are exposed to abrasive materials, high-velocity flue gases, and temperatures up to 600°C. The high chromium content enhances resistance to oxidizing environments, while the hardened structure ensures long-lasting wear protection in areas such as superheaters, reheaters, economizers, and water-cooled wall tubes.

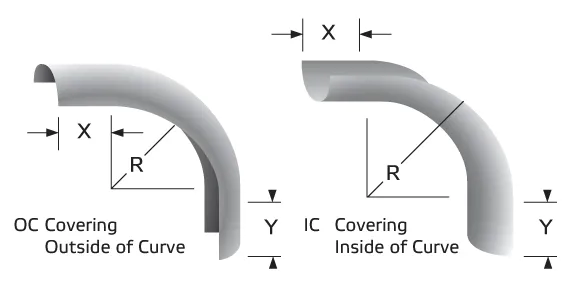

1Cr13 shields are commonly paired with other alloys like 1Cr6Si2Mo or TP321 for extended protection in severe conditions. Available in multiple geometries—including straight, curved, in-curve, outer-curve, side-curve, and S-curve—these shields are customizable for tube outer diameters (OD) ranging from 32 mm to 89 mm, such as 38, 42, 48, 57, and 76 mm. Wrap angles typically range from 120° to 180°, with thickness options from 2 mm to 5 mm.

Installation methods include spot welding, clamp-on mounting, or snap ring attachment using stainless clips (C-type or U-type, made from 304 or 310S). Manufactured using high-pressure molds, these shields ensure tight fit, smooth finish, and weldability. Regular inspection and replacement during overhauls (every 3–5 years) help prevent failures and minimize maintenance downtime.

1Cr13 stainless steel (AISI 410) for strength and moderate corrosion resistance.

Straight, curved, S-curve, in/outer/side curve configurations.

2 mm – 5 mm depending on wear severity and thermal needs.

Fits OD 32–89 mm tubes (customizable sizes).

Spot welding, clamp-on, or snap ring attachment (C/U clips).

Extends boiler tube life in high-temperature and abrasive environments.

Reduces maintenance costs and prevents unplanned shutdowns.

Supports safe, efficient operation in power and petrochemical plants.

Alternative alloys or coatings available for critical zones.

Coal and gas-fired boilers – protects against fly ash erosion.

Shields heat exchanger tubes from corrosion.

Maintains integrity under high-temperature refining conditions.

Protects tubes exposed to reactive particles and gas.

Guards tubes in flue gas and corrosive ash zones.

Cost-effective balance of strength and corrosion resistance for ≤600°C environments.

Chromium carbide coatings and alternate materials like TP321 or 1Cr6Si2Mo available.

Replace worn shields every 3–5 years during boiler overhauls.

ASME-compliant for modern retrofit compatibility.

1Cr13 (410) stainless steel is one of the representative of martensitic stainless steel. Martensitic stainless steels are stainless steels [TJC STEEL]whose strength and properties can be improved by heat treatment.

Martensitic stainless steel wear protection for industrial boiler and heat exchanger tubes.

| Element | Content (%) |

|---|---|

| C | ≤0.15 |

| Si | ≤0.60 |

| Mn | ≤0.60 |

| P | ≤0.035 |

| S | ≤0.030 |

| Cr | 12.0–14.0 |

| Ni | ≤0.60 |

| Property | Value |

|---|---|

| Tensile Strength | 450–700 MPa |

| Yield Strength | ≥280 MPa |

| Hardness | 180–240 HB |

| Elongation | ≥20% |

| Max Service Temperature | 600–650°C |

| Feature | 1Cr13 (410) | 304 | 316 |

|---|---|---|---|

| Structure | Martensitic | Austenitic | Austenitic |

| Cr Content (%) | 12–14 | 18–20 | 16–18 |

| Ni Content (%) | ≤0.6 | 8–10.5 | 10–14 |

| Mo Content (%) | — | — | 2–3 |

| Corrosion Resistance | ★★☆☆☆ | ★★★★☆ | ★★★★★ |

| Wear Resistance | ★★★★☆ | ★★☆☆☆ | ★★☆☆☆ |

| Heat Resistance | ★★★☆☆ | ★★★★☆ | ★★★★★ |

| Cost | ★☆☆☆☆ (Low) | ★★★☆☆ (Medium) | ★★★★☆ (High) |

| Best Use Case | Erosion Zones | Steam / Chlorides | Chlorides + Acid |

We stock stainless steels in a multitude of shapes and sizes.

We support our stainless steel stock with a wide range of shapes and sizes to suit your engineering applications. We hold thirteen different types of shapes to support the grades of material we stock, including bars, sheets and plates.

Stainless Carbon Steel Composite Pipe

Sort:99

Material-Specific Erosion Shields

Sort:99

| Grade | C (% max) | Mn (% max) | Si (% max) | P (% max) | S (% max) | Cr (%) | Ni (%) | Mo (%) | N (% max) |

|---|---|---|---|---|---|---|---|---|---|

| 304 | 0.08 | 2.00 | 1.00 | 0.045 | 0.030 | 18.0-20.0 | 8.0-11.0 | - | 0.10 |

| 304L | 0.03 | 2.00 | 1.00 | 0.045 | 0.030 | 18.0-20.0 | 8.0-12.0 | - | 0.10 |

| 316 | 0.08 | 2.00 | 1.00 | 0.045 | 0.030 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 | 0.10 |

| 316L | 0.03 | 2.00 | 1.00 | 0.045 | 0.030 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 | 0.10 |

The low carbon content in 304L and 316L enhances weldability, while molybdenum in 316 and 316L improves resistance to pitting and crevice corrosion, making 1Cr13 Boiler Tube Shield ideal for harsh environments.

| Grade | Tensile Strength (min, MPa) | Yield Strength (min, MPa) | Elongation (min, %) | Hardness (max, HB) | Hardness (max, HRB) |

|---|---|---|---|---|---|

| 304 | 515 | 205 | 40 | 201 | 92 |

| 304L | 485 | 170 | 40 | 201 | 92 |

| 316 | 515 | 205 | 40 | 217 | 95 |

| 316L | 485 | 170 | 40 | 217 | 95 |

These mechanical properties make 1Cr13 Boiler Tube Shield suitable for applications requiring high strength and corrosion resistance, such as architectural structures, marine environments, and chemical processing.

In order to solve the cumbersome and difficult to remember stainless steel grades, improve the practicability of the brand representation, and the contrast with the international standard grades, China has formulated the "Universal Code System for Steel and Alloy Grades", such as 06Cr19Ni10, corresponding to 304. Different grades of stainless steel have different ingredients, but they all have a national standard. The standards of each country are also different.

| No | China (GB) | Japan (JIS) | American | Korea (KS) | EU (BS EN) | India (IS) | Australia (AS) | Taiwan (CNS) | ||

|---|---|---|---|---|---|---|---|---|---|---|

| Old | New (07.10) | SUS | ASTM | UNS | STS | EN | IS | AS | CNS | |

| Austenitic Stainless Steel | ||||||||||

| 1 | 1Cr17Mn6Ni5N | 12Cr17Mn6Ni5N | SUS201 | 201 | S20100 | STS201 | 1.4372 | 10Cr17Mn6Ni4N20 | 201-2 | 201 |

| 2 | 1Cr18Mn8Ni5N | 12Cr18Mn9Ni5N | SUS202 | 202 | S20200 | STS202 | 1.4373 | — | — | 202 |

| 3 | 1Cr17Ni7 | 12Cr17Ni7 | SUS301 | 301 | S30100 | STS301 | 1.4319 | 10Cr17Ni7 | 301 | 301 |

| 4 | 0Cr18Ni9 | 06Cr19Ni10 | SUS304 | 304 | S30400 | STS304 | 1.4301 | 07Cr18Ni9 | 304 | 304 |

| 5 | 00Cr19Ni10 | 022Cr19Ni10 | SUS304L | 304L | S30403 | STS304L | 1.4306 | 02Cr18Ni11 | 304L | 304L |

| 6 | 0Cr19Ni9N | 06Cr19Ni10N | SUS304N1 | 304N | S30451 | STS304N1 | 1.4315 | — | 304N1 | 304N1 |

| 7 | 0Cr19Ni10NbN | 06Cr19Ni9NbN | SUS304N2 | XM21 | S30452 | STS304N2 | — | — | 304N2 | 304N2 |

| 8 | 00Cr18Ni10N | 022Cr19Ni10N | SUS304LN | 304LN | S30453 | STS304LN | — | — | 304LN | 304LN |

| 9 | 1Cr18Ni12 | 10Cr18Ni12 | SUS305 | 305 | S30500 | STS305 | 1.4303 | — | 305 | 305 |

| 10 | 0Cr23Ni13 | 06Cr23Ni13 | SUS309S | 309S | S30908 | STS309S | 1.4833 | — | 309S | 309S |

| 11 | 0Cr25Ni20 | 06Cr25Ni20 | SUS310S | 310S | S31008 | STS310S | 1.4845 | — | 310S | 310S |

| 12 | 0Cr17Ni12Mo2 | 06Cr17Ni12Mo2 | SUS316 | 316 | S31600 | STS316 | 1.4401 | 04Cr17Ni12Mo2 | 316 | 316 |

| 13 | 0Cr18Ni12Mo3Ti | 06Cr17Ni12Mo2Ti | SUS316Ti | 316Ti | S31635 | — | 1.4571 | 04Cr17Ni12MoTi20 | 316Ti | 316Ti |

| 14 | 00Cr17Ni14Mo2 | 022Cr17Ni12Mo2 | SUS316L | 316L | S31603 | STS316L | 1.4404 | 02Cr17Ni12Mo2 | 316L | 316L |

| 15 | 0Cr17Ni12Mo2N | 06Cr17Ni12Mo2N | SUS316N | 316N | S31651 | STS316N | — | — | 316N | 316N |

| 16 | 00Cr17Ni13Mo2N | 022Cr17Ni13Mo2N | SUS316LN | 316LN | S31653 | STS316LN | 1.4429 | — | 316LN | 316LN |

| 17 | 0Cr18Ni12Mo2Cu2 | 06Cr18Ni12Mo2Cu2 | SUS316J1 | — | — | STS316J1 | — | — | 316J1 | 316J1 |

| 18 | 00Cr18Ni14Mo2Cu2 | 022Cr18Ni14Mo2Cu2 | SUS316J1L | — | — | STS316J1L | — | — | — | 316J1L |

| 19 | 0Cr19Ni13Mo3 | 06Cr19Ni13Mo3 | SUS317 | 317 | S31700 | STS317 | — | — | 317 | 317 |

| 20 | 00Cr19Ni13Mo3 | 022Cr19Ni13Mo3 | SUS317L | 317L | S31703 | STS317L | 1.4438 | — | 317L | 317L |

| 21 | 0Cr18Ni10Ti | 06Cr18Ni11Ti | SUS321 | 321 | S32100 | STS321 | 1.4541 | 04Cr18Ni10Ti20 | 321 | 321 |

| 22 | 0Cr18Ni11Nb | 06Cr18Ni11Nb | SUS347 | 347 | S34700 | STS347 | 1.4550 | 04Cr18Ni10Nb40 | 347 | 347 |

| Austenitic-Ferritic Stainless Steel (Duplex) | ||||||||||

| 23 | 0Cr26Ni5Mo2 | — | SUS329J1 | 329 | S32900 | STS329J1 | 1.4477 | — | 329J1 | 329J1 |

| 24 | 00Cr18Ni5Mo3Si2 | 022Cr19Ni5Mo3Si2N | SUS329J3L | — | S31803 | STS329J3L | 1.4462 | — | 329J3L | 329J3L |

| Ferritic Stainless Steel | ||||||||||

| 25 | 0Cr13Al | 06Cr13Al | SUS405 | 405 | S40500 | STS405 | 1.4002 | 04Cr13 | 405 | 405 |

| 26 | — | 022Cr11Ti | SUH409 | 409 | S40900 | STS409 | 1.4512 | — | 409L | 409L |

| 27 | 00Cr12 | 022Cr12 | SUS410L | — | — | STS410L | — | — | 410L | 410L |

| 28 | 1Cr17 | 10Cr17 | SUS430 | 430 | S43000 | STS430 | 1.4016 | 05Cr17 | 430 | 430 |

| 29 | 1Cr17Mo | 10Cr17Mo | SUS434 | 434 | S43400 | STS434 | 1.4113 | — | 434 | 434 |

| 30 | — | 022Cr18NbTi | — | — | S43940 | — | 1.4509 | — | 439 | 439 |

| 31 | 00Cr18Mo2 | 019Cr19Mo2NbTi | SUS444 | 444 | S44400 | STS444 | 1.4521 | — | 444 | 444 |

| Martensitic Stainless Steel | ||||||||||

| 32 | 1Cr12 | 12Cr12 | SUS403 | 403 | S40300 | STS403 | — | — | 403 | 403 |

| 33 | 1Cr13 | 12Cr13 | SUS410 | 410 | S41000 | STS410 | 1.4006 | 12Cr13 | 410 | 410 |

| 34 | 2Cr13 | 20Cr13 | SUS420J1 | 420 | S42000 | STS420J1 | 1.4021 | 20Cr13 | 420 | 420J1 |

| 35 | 3Cr13 | 30Cr13 | SUS420J2 | — | — | STS420J2 | 1.4028 | 30Cr13 | 420J2 | 420J2 |

| 36 | 7Cr17 | 68Cr17 | SUS440A | 440A | S44002 | STS440A | — | — | 440A | 440A |

316L Tube Shield ET Wear Shield

Sort:0

309S Stainless Ferrules & Fittings – Erosion Shield Solutions for Superheater Tubes

Sort:0

316L Stainless Steel Erosion Shields for Corrosion & Wear Resistance

Sort:0

310S Stainless Steel Erosion Shields for Steam Boiler Tubes

Sort:0