Boiler Protection

316 stainless steel tube shields protect boiler tubes from wear and corrosion in harsh industrial environments.

Boiler Protection

316 stainless steel tube shields protect boiler tubes from wear and corrosion in harsh industrial environments. durable, customizable shields extend tube life in power plants and mining pipelines.

Premium protective sleeves engineered for superior erosion, corrosion, and wear resistance in demanding industrial environments.

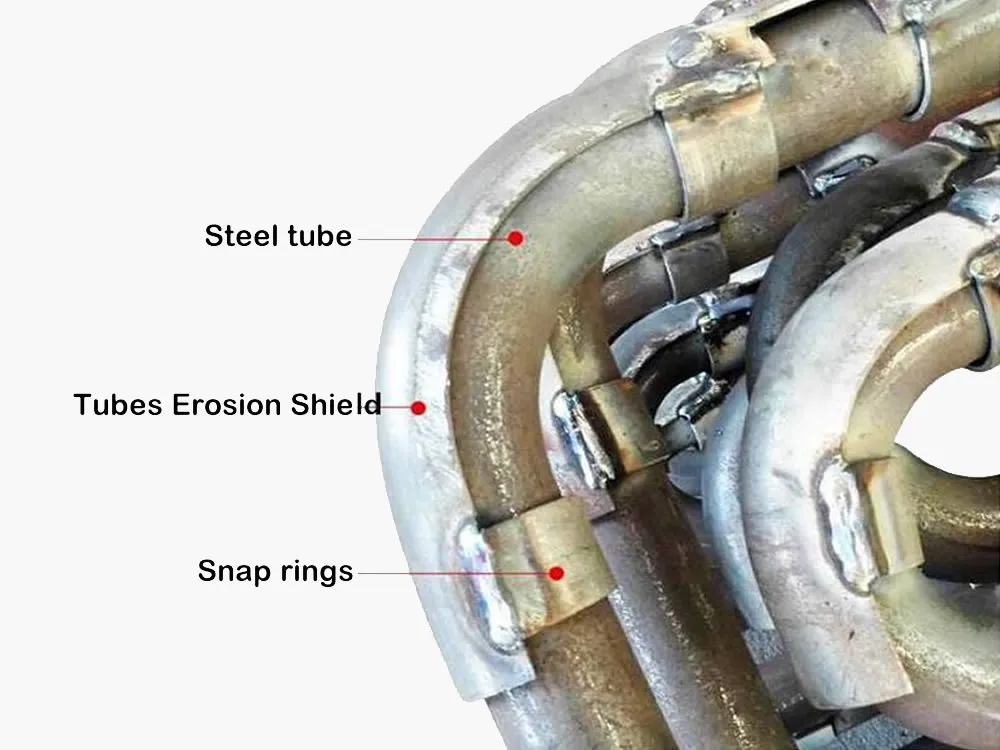

The Stainless 316 Tube Shield is a premium protective sleeve made from 316 stainless steel, designed to safeguard boiler tubes, superheater tubes, and process piping against erosion, corrosion, and mechanical wear. It is widely used in power plants, chemical processing facilities, and industrial plants exposed to aggressive environments such as acidic flue gases, high humidity, and abrasive particles.

Constructed with 316 stainless steel, known for its outstanding corrosion resistance—especially against chlorides—and good mechanical strength, the shield protects tubes from premature failure caused by pitting, crevice corrosion, and mechanical erosion. The low carbon content in 316 stainless steel minimizes carbide precipitation during welding, enhancing durability in high-temperature applications.

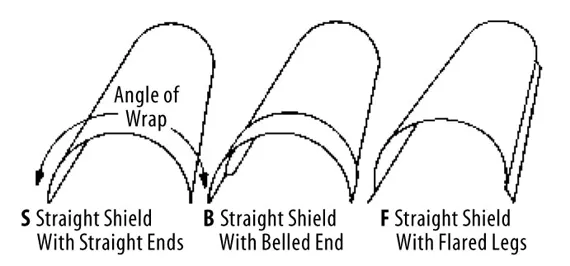

These tube shields come in various forms including U-shaped half shells and fully enclosed sleeves, allowing easy installation via welding or mechanical clamps. Typical thickness ranges from 1.5mm to 2.5mm, tailored to meet specific operational requirements.

Manufactured from 316 stainless steel (UNS S31600), a molybdenum-bearing austenitic alloy, these shields offer superior resistance to pitting, crevice corrosion, and chemical attack, particularly in chloride-rich or acidic environments. They are widely used in power plant transport systems, mining pipelines, waste-to-energy boilers, and chemical recovery boilers, where tubes face abrasive and corrosive conditions.

The molybdenum content enhances corrosion resistance against acid condensate and wet flue gases, making these tube shields ideal for protecting superheater tubes, economizer sections, and moisture-prone zones. Their mechanical stability ensures reliable performance under high-temperature and high-stress conditions, while resistance to erosion-corrosion coupling is critical in wet ash transport zones. These wear-resistant shields mitigate tube thinning at critical points such as bends, slopes, and flue-impact areas, significantly extending tube lifespan and reducing maintenance costs.

316/316L stainless steel is widely used in chloride and chemical process environments due to its enhanced resistance to corrosion and pitting, attributed to its molybdenum content. These alloys offer excellent mechanical and corrosion-resistant properties across a range of temperatures and environments, making them essential in chemical processing, marine, and high-temperature industrial applications.

Low carbon version of 316, offering superior resistance to intergranular corrosion after welding. Commonly used in marine and chloride-rich environments. Excellent weldability without post-weld annealing.

High carbon content variant suitable for elevated temperature service. Offers greater short and long-term creep strength. Commonly used in high-stress boiler or furnace applications.

Standard molybdenum-bearing austenitic stainless steel. Excellent resistance to chlorides and moderate acids. Widely used across various chemical and process industries.

| Grade | 316 | 316L |

|---|---|---|

| UNS | S31600 | S31603 |

| Carbon (C) Max. | 0.08 | 0.030 |

| Manganese (Mn) Max. | 2.00 | 2.00 |

| Phosphorus (P) Max. | 0.045 | 0.045 |

| Sulfur (S) Max. | 0.030 | 0.030 |

| Silicon (Si) Max. | 1.00 | 1.00 |

| Chromium (Cr) | 16.0–18.0 | 16.0–18.0 |

| Nickel (Ni) | 10.0–14.0 | 10.0–14.0 |

| Molybdenum (Mo) | 2.0–3.0 | 2.0–3.0 |

| Iron (Fe) | Balance | |

Chemical composition details for 316 and 316L stainless steels used in corrosion-resistant applications.

| Material | Form | Tensile Strength (ksi) | Yield Strength (ksi) | Elongation (%) | Hardness (HB) |

|---|---|---|---|---|---|

| Alloy 316L | Sheet AMS 5507 | 100 max | - | 45 | - |

| Alloy 316 | Sheet AMS 5524 | 75 min | 30 | 45 | 207 max |

Typical mechanical properties for 316 and 316L stainless steel sheets used in industrial applications.

| Electrical Resistivity | Magnetic Permeability |

|---|---|

| 7.2e-005 ohm-cm | 1.008 |

| 1.16e-004 at 650°C | RT |

Electrical resistivity and magnetic permeability values at room and elevated temperatures.

| Alloy | UNS | Tensile (MPa) | Yield (MPa) | Elongation (%) | Hardness |

|---|---|---|---|---|---|

| 316 | S31600 | 515 | 205 | 35 | 90 Rb |

| 316L | S31603 | 485 | 170 | - | 90 Rb |

Physical and mechanical properties comparison for 316 and 316L stainless steels.

316L is preferred when welding thick sections is necessary and when resistance to intergranular corrosion is critical. 316H is used for elevated temperature pressure services.

We stock stainless steels in a multitude of shapes and sizes.

We support our stainless steel stock with a wide range of shapes and sizes to suit your engineering applications. We hold thirteen different types of shapes to support the grades of material we stock, including bars, sheets and plates.

Stainless Carbon Steel Composite Pipe

Sort:99

Material-Specific Erosion Shields

Sort:99

Boiler tube erosion shields are typically attached using the following methods:

Yes,

we provide custom straight boiler tube shields based on customer requirements.

These can be tailored in shape, size, and material to suit specific boiler configurations.

Boiler tubes erosion shields protect critical boiler components from wear and corrosion, ensuring durability and efficiency across multiple industries.

Protects boiler tubes in coal-fired, natural gas, biomass, and waste-to-energy plants from abrasive flue gases and high temperatures.

Shields tubes in petrochemical, pulp and paper, food processing, and manufacturing boilers, reducing wear and maintenance costs.

Provides corrosion-resistant protection for marine boiler systems and offshore platform boilers in harsh, corrosive environments.

Enhances tube durability in gas turbine exhausts and industrial process systems, improving energy efficiency and longevity.

Reduces downtime with easy-to-install shields for straight, bent, and finned tubes, ensuring long-term boiler reliability.

Custom shields for unique boiler configurations, protecting against abrasive particles and high-pressure conditions.

| Industry | Application |

|---|---|

| Coal-Fired Power Plants | Protects superheaters, reheaters, and economizers from abrasive ash and flue gas erosion. |

| Natural Gas Combined Cycle | Shields tubes in high-pressure boilers from wear caused by high-velocity gas flows. |

| Biomass Power Stations | Reduces tube wear in boilers handling abrasive biomass materials like wood chips. |

| Waste-to-Energy Plants | Protects tubes from corrosion and erosion in incineration and waste processing systems. |

| Petrochemical Facilities | Ensures durability of boiler tubes in high-temperature, corrosive chemical environments. |

| Pulp and Paper Mills | Shields boiler tubes from wear in steam generation systems for paper production. |

| Food Processing Plants | Protects steam boiler tubes from wear and corrosion in hygienic processing environments. |

| Marine Boiler Systems | Provides corrosion-resistant protection for tubes in harsh marine environments. |

| Offshore Platform Boilers | Ensures tube longevity in remote, corrosive offshore conditions with minimal maintenance. |

| Heat Recovery Steam Generators | Enhances tube life in systems recovering heat from gas turbine exhausts. |

| Industrial Process Exhausts | Protects tubes in waste heat recovery systems handling variable, abrasive exhausts. |

316L Tube Shield ET Wear Shield

Sort:0

309S Stainless Ferrules & Fittings – Erosion Shield Solutions for Superheater Tubes

Sort:0

316L Stainless Steel Erosion Shields for Corrosion & Wear Resistance

Sort:0

310S Stainless Steel Erosion Shields for Steam Boiler Tubes

Sort:0