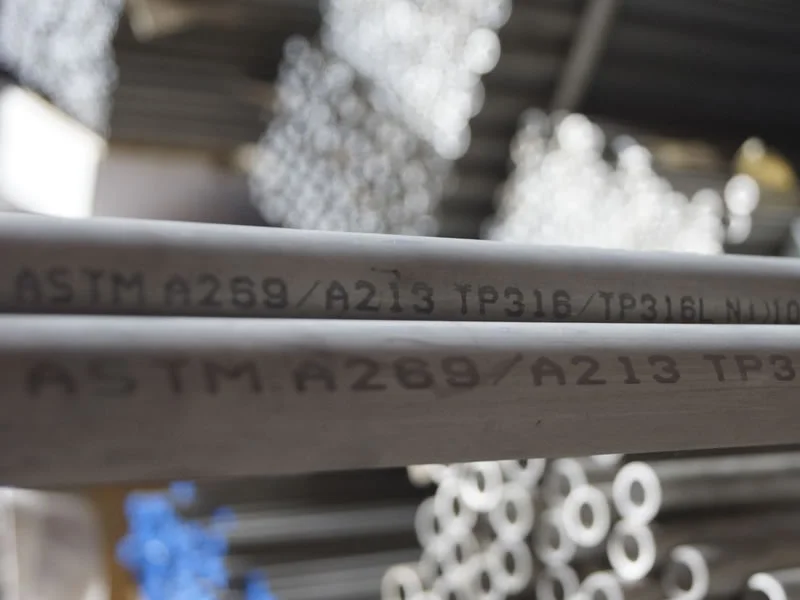

Astm a269 tp316l stainless tube refers to a specific type of stainless steel tubing that conforms to the astm a269 standard and is made from grade tp316l stainless steel.

The ASTM A269 TP316L Stainless Tube is a high-performance tubing solution designed for superior corrosion resistance in demanding industrial applications, including chemical processing, marine environments, and sanitary systems. Compliant with ASTM A269 for seamless and welded austenitic stainless steel tubing for general service, TP316L offers low carbon content for enhanced weldability and exceptional resistance to pitting and crevice corrosion due to its molybdenum content. Ideal for high-pressure systems up to 4500 psi and temperatures from -196°C to 650°C, these Corrosion Resistant Stainless Tubes are widely used in pharmaceuticals, food processing, and offshore platforms.

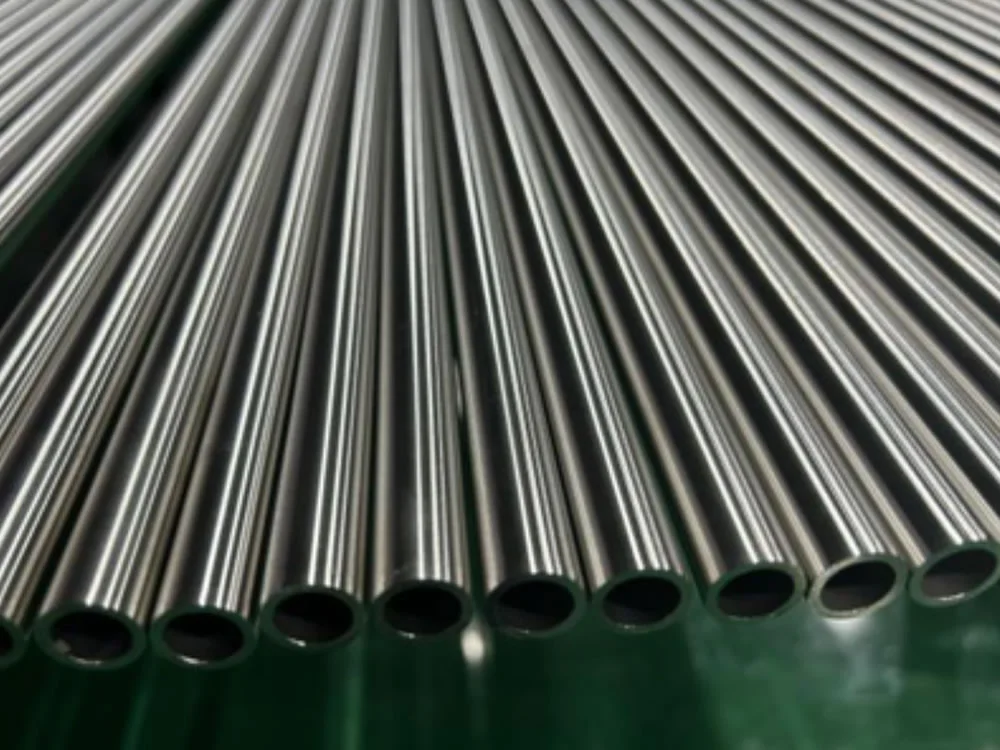

Available in Seamless Stainless Tube and Welded Stainless Tube configurations, TP316L tubes are produced via extrusion for seamless variants or strip welding for welded options, ensuring versatility for diverse applications. Seamless tubes provide structural integrity for high-pressure heat exchangers or boiler systems, while welded tubes offer cost-efficiency for larger diameters and lower-pressure systems. Sizes range from 1/8" to 12" (DN6 to DN300) with wall thicknesses from 0.010" to 0.5" (SCH 5S to SCH 80S). Surface finishes like annealed, pickled, or electropolished meet stringent hygiene standards for food-grade and pharmaceutical applications, while NACE MR0175 compliance ensures reliability in sour service environments like oil and gas.

The TP316L Stainless Tube boasts tensile strength ≥515 MPa, yield strength ≥205 MPa, and elongation ≥35%, enabling bending, flaring, and welding without cracking. Its chemical composition, with 16-18% chromium, 10-14% nickel, and 2-3% molybdenum, forms a robust passive oxide layer for self-healing corrosion resistance, particularly against chlorides in marine or chemical settings. Heat treatments ensure low thermal expansion for cryogenic applications, while rigorous testing—tensile, flattening, and hydrostatic—per ASTM A269 guarantees compliance. Custom options like cut-to-length or beveled ends facilitate integration into complex systems.

Compared to TP304, the ASTM A269 TP316L Tube offers superior resistance to pitting and stress corrosion cracking, making it ideal for aggressive environments where TP304 may falter. Versus carbon steel tubes, it provides 2-3 times better corrosion resistance, eliminating frequent maintenance in acidic or seawater conditions. Long-tail keywords like “ASTM A269 TP316L stainless tube for chemical processing” or “welded TP316L tube for sanitary systems” align with NSF 61 and ASME BPE standards. Its lifespan of up to 50 years and 30-40% lower lifecycle costs compared to carbon steel make it a cost-effective choice for high-reliability applications.

Addressing challenges like biofouling in water systems and erosion in high-velocity flows, the Corrosion Resistant Stainless Tube incorporates alloy enhancements like nitrogen for improved pitting resistance. Its 100% recyclability aligns with eco-friendly regulations, supporting sustainable practices. Whether used in heat exchangers, chemical reactors, or food-grade pipelines, the ASTM A269 TP316L Stainless Tube delivers unmatched durability, versatility, and performance for global industrial needs.

Below are specifications for ASTM A269 TP316L Stainless Tube, focusing on its chemical composition and mechanical properties for seamless and welded applications. Data aligns with ASTM A269 standards.

| Grade | Chemical Composition (%) | Mechanical Properties |

|---|---|---|

| TP316L |

|

|

The surface finish determines cleanliness, corrosion resistance, and suitability for different industries. Below is a quick comparison of AP, MP, BA, and EP finishes.

| Finish | Full Name | Process | Surface Look | Typical Applications |

|---|---|---|---|---|

| AP | Annealed & Pickled | Heat treated and acid pickled to remove oxide scale | Matte, oxide-free | Chemical and petrochemical pipelines |

| MP | Mechanical Polished | Mechanically polished after AP treatment | Smooth, bright | Pharmaceutical, food, and dairy industries |

| BA | Bright Annealed | Annealed in argon atmosphere, no pickling | Reflective, clean | Precision instruments, decorative uses |

| EP | Electropolished | Electrochemical polishing after AP | Mirror-like, ultra clean | Biotech, semiconductor, high-purity water systems |

The versatility of ASTM A269 stainless steel tubes lends itself to a wide array of applications across multiple industries, ensuring safety, hygiene, and durability.

In aggressive chemical environments, where corrosion resistance is critical, ASTM A269 tubes are used for transporting and containing corrosive fluids and gases.

Ensuring hygienic and sterile environments, ASTM A269 stainless steel tubes are used for processes involving high-purity fluids and gases in pharmaceutical production.

For the safe transport of consumable products, ASTM A269 tubing ensures no contaminants leach into food and beverages, supporting safety and quality standards.

Engineered for superior corrosion resistance and reliability in demanding applications.

We stock stainless steels in a multitude of shapes and sizes.

We support our stainless steel stock with a wide range of shapes and sizes to suit your engineering applications. We hold thirteen different types of shapes to support the grades of material we stock, including bars, sheets and plates.

Stainless Carbon Steel Composite Pipe

Sort:99

Material-Specific Erosion Shields

Sort:99

| Grade | C (% max) | Mn (% max) | Si (% max) | P (% max) | S (% max) | Cr (%) | Ni (%) | Mo (%) | N (% max) |

|---|---|---|---|---|---|---|---|---|---|

| 304 | 0.08 | 2.00 | 1.00 | 0.045 | 0.030 | 18.0-20.0 | 8.0-11.0 | - | 0.10 |

| 304L | 0.03 | 2.00 | 1.00 | 0.045 | 0.030 | 18.0-20.0 | 8.0-12.0 | - | 0.10 |

| 316 | 0.08 | 2.00 | 1.00 | 0.045 | 0.030 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 | 0.10 |

| 316L | 0.03 | 2.00 | 1.00 | 0.045 | 0.030 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 | 0.10 |

The low carbon content in 304L and 316L enhances weldability, while molybdenum in 316 and 316L improves resistance to pitting and crevice corrosion, making ASTM A269 TP316L stainless tube ideal for harsh environments.

| Grade | Tensile Strength (min, MPa) | Yield Strength (min, MPa) | Elongation (min, %) | Hardness (max, HB) | Hardness (max, HRB) |

|---|---|---|---|---|---|

| 304 | 515 | 205 | 40 | 201 | 92 |

| 304L | 485 | 170 | 40 | 201 | 92 |

| 316 | 515 | 205 | 40 | 217 | 95 |

| 316L | 485 | 170 | 40 | 217 | 95 |

These mechanical properties make ASTM A269 TP316L stainless tube suitable for applications requiring high strength and corrosion resistance, such as architectural structures, marine environments, and chemical processing.

In order to solve the cumbersome and difficult to remember stainless steel grades, improve the practicability of the brand representation, and the contrast with the international standard grades, China has formulated the "Universal Code System for Steel and Alloy Grades", such as 06Cr19Ni10, corresponding to 304. Different grades of stainless steel have different ingredients, but they all have a national standard. The standards of each country are also different.

| No | China (GB) | Japan (JIS) | American | Korea (KS) | EU (BS EN) | India (IS) | Australia (AS) | Taiwan (CNS) | ||

|---|---|---|---|---|---|---|---|---|---|---|

| Old | New (07.10) | SUS | ASTM | UNS | STS | EN | IS | AS | CNS | |

| Austenitic Stainless Steel | ||||||||||

| 1 | 1Cr17Mn6Ni5N | 12Cr17Mn6Ni5N | SUS201 | 201 | S20100 | STS201 | 1.4372 | 10Cr17Mn6Ni4N20 | 201-2 | 201 |

| 2 | 1Cr18Mn8Ni5N | 12Cr18Mn9Ni5N | SUS202 | 202 | S20200 | STS202 | 1.4373 | — | — | 202 |

| 3 | 1Cr17Ni7 | 12Cr17Ni7 | SUS301 | 301 | S30100 | STS301 | 1.4319 | 10Cr17Ni7 | 301 | 301 |

| 4 | 0Cr18Ni9 | 06Cr19Ni10 | SUS304 | 304 | S30400 | STS304 | 1.4301 | 07Cr18Ni9 | 304 | 304 |

| 5 | 00Cr19Ni10 | 022Cr19Ni10 | SUS304L | 304L | S30403 | STS304L | 1.4306 | 02Cr18Ni11 | 304L | 304L |

| 6 | 0Cr19Ni9N | 06Cr19Ni10N | SUS304N1 | 304N | S30451 | STS304N1 | 1.4315 | — | 304N1 | 304N1 |

| 7 | 0Cr19Ni10NbN | 06Cr19Ni9NbN | SUS304N2 | XM21 | S30452 | STS304N2 | — | — | 304N2 | 304N2 |

| 8 | 00Cr18Ni10N | 022Cr19Ni10N | SUS304LN | 304LN | S30453 | STS304LN | — | — | 304LN | 304LN |

| 9 | 1Cr18Ni12 | 10Cr18Ni12 | SUS305 | 305 | S30500 | STS305 | 1.4303 | — | 305 | 305 |

| 10 | 0Cr23Ni13 | 06Cr23Ni13 | SUS309S | 309S | S30908 | STS309S | 1.4833 | — | 309S | 309S |

| 11 | 0Cr25Ni20 | 06Cr25Ni20 | SUS310S | 310S | S31008 | STS310S | 1.4845 | — | 310S | 310S |

| 12 | 0Cr17Ni12Mo2 | 06Cr17Ni12Mo2 | SUS316 | 316 | S31600 | STS316 | 1.4401 | 04Cr17Ni12Mo2 | 316 | 316 |

| 13 | 0Cr18Ni12Mo3Ti | 06Cr17Ni12Mo2Ti | SUS316Ti | 316Ti | S31635 | — | 1.4571 | 04Cr17Ni12MoTi20 | 316Ti | 316Ti |

| 14 | 00Cr17Ni14Mo2 | 022Cr17Ni12Mo2 | SUS316L | 316L | S31603 | STS316L | 1.4404 | 02Cr17Ni12Mo2 | 316L | 316L |

| 15 | 0Cr17Ni12Mo2N | 06Cr17Ni12Mo2N | SUS316N | 316N | S31651 | STS316N | — | — | 316N | 316N |

| 16 | 00Cr17Ni13Mo2N | 022Cr17Ni13Mo2N | SUS316LN | 316LN | S31653 | STS316LN | 1.4429 | — | 316LN | 316LN |

| 17 | 0Cr18Ni12Mo2Cu2 | 06Cr18Ni12Mo2Cu2 | SUS316J1 | — | — | STS316J1 | — | — | 316J1 | 316J1 |

| 18 | 00Cr18Ni14Mo2Cu2 | 022Cr18Ni14Mo2Cu2 | SUS316J1L | — | — | STS316J1L | — | — | — | 316J1L |

| 19 | 0Cr19Ni13Mo3 | 06Cr19Ni13Mo3 | SUS317 | 317 | S31700 | STS317 | — | — | 317 | 317 |

| 20 | 00Cr19Ni13Mo3 | 022Cr19Ni13Mo3 | SUS317L | 317L | S31703 | STS317L | 1.4438 | — | 317L | 317L |

| 21 | 0Cr18Ni10Ti | 06Cr18Ni11Ti | SUS321 | 321 | S32100 | STS321 | 1.4541 | 04Cr18Ni10Ti20 | 321 | 321 |

| 22 | 0Cr18Ni11Nb | 06Cr18Ni11Nb | SUS347 | 347 | S34700 | STS347 | 1.4550 | 04Cr18Ni10Nb40 | 347 | 347 |

| Austenitic-Ferritic Stainless Steel (Duplex) | ||||||||||

| 23 | 0Cr26Ni5Mo2 | — | SUS329J1 | 329 | S32900 | STS329J1 | 1.4477 | — | 329J1 | 329J1 |

| 24 | 00Cr18Ni5Mo3Si2 | 022Cr19Ni5Mo3Si2N | SUS329J3L | — | S31803 | STS329J3L | 1.4462 | — | 329J3L | 329J3L |

| Ferritic Stainless Steel | ||||||||||

| 25 | 0Cr13Al | 06Cr13Al | SUS405 | 405 | S40500 | STS405 | 1.4002 | 04Cr13 | 405 | 405 |

| 26 | — | 022Cr11Ti | SUH409 | 409 | S40900 | STS409 | 1.4512 | — | 409L | 409L |

| 27 | 00Cr12 | 022Cr12 | SUS410L | — | — | STS410L | — | — | 410L | 410L |

| 28 | 1Cr17 | 10Cr17 | SUS430 | 430 | S43000 | STS430 | 1.4016 | 05Cr17 | 430 | 430 |

| 29 | 1Cr17Mo | 10Cr17Mo | SUS434 | 434 | S43400 | STS434 | 1.4113 | — | 434 | 434 |

| 30 | — | 022Cr18NbTi | — | — | S43940 | — | 1.4509 | — | 439 | 439 |

| 31 | 00Cr18Mo2 | 019Cr19Mo2NbTi | SUS444 | 444 | S44400 | STS444 | 1.4521 | — | 444 | 444 |

| Martensitic Stainless Steel | ||||||||||

| 32 | 1Cr12 | 12Cr12 | SUS403 | 403 | S40300 | STS403 | — | — | 403 | 403 |

| 33 | 1Cr13 | 12Cr13 | SUS410 | 410 | S41000 | STS410 | 1.4006 | 12Cr13 | 410 | 410 |

| 34 | 2Cr13 | 20Cr13 | SUS420J1 | 420 | S42000 | STS420J1 | 1.4021 | 20Cr13 | 420 | 420J1 |

| 35 | 3Cr13 | 30Cr13 | SUS420J2 | — | — | STS420J2 | 1.4028 | 30Cr13 | 420J2 | 420J2 |

| 36 | 7Cr17 | 68Cr17 | SUS440A | 440A | S44002 | STS440A | — | — | 440A | 440A |

Seamless pipes are critical in various industries thanks to their excellent strength, temperature resistance, and structural uniformity. They ensure safe and efficient performance in demanding environments.

Used in steam pipelines, boiler tubes, superheaters, and heat exchangers for high-temperature and high-pressure conditions in power plants.

Transports crude oil, natural gas, and petroleum products in pipelines and refinery units, handling high-pressure and corrosion.

Handles chemicals, gases, and hazardous substances in reactors and heat exchangers, ensuring safe processing.

Applied in automotive systems and machinery for fluid conveyance and precision components requiring strength and accuracy.

Used in structural support, water and sewage systems, and building frameworks for strength and corrosion resistance.

Utilized in hydraulic and engine systems onboard, resisting corrosion in marine environments.

Employed in aircraft and military equipment for hydraulic systems and structural components.

Stainless pipes for hygienic transport of food and pharmaceutical products, maintaining sterility.

Designed for transporting slurries and chemicals in mining, withstanding abrasion and harsh conditions.

Ferritic stainless steel tubes

Sort:0

Customized Alumina Ceramic Lined Project

Sort:99

High Chromium Alloy Lined Pipe

Sort:99

Sort:0

Wear-Resistant Hardfacing Liner Plate

Sort:0