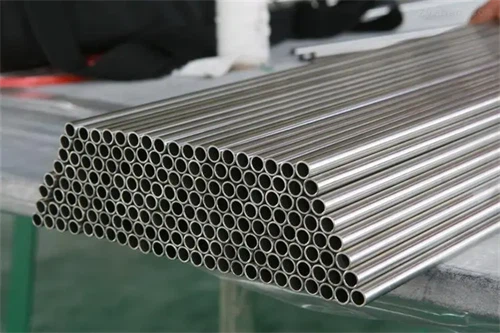

Stainless heat exchanger tubes are precision-engineered seamless or welded components designed for efficient thermal transfer in demanding environments, offering unmatched corrosion resistant exchanger pipes and boiler exchanger protection.

Stainless heat exchanger tubes are precision-engineered seamless or welded components designed for efficient thermal transfer in demanding environments, offering unmatched corrosion resistant exchanger pipes and boiler exchanger protection.

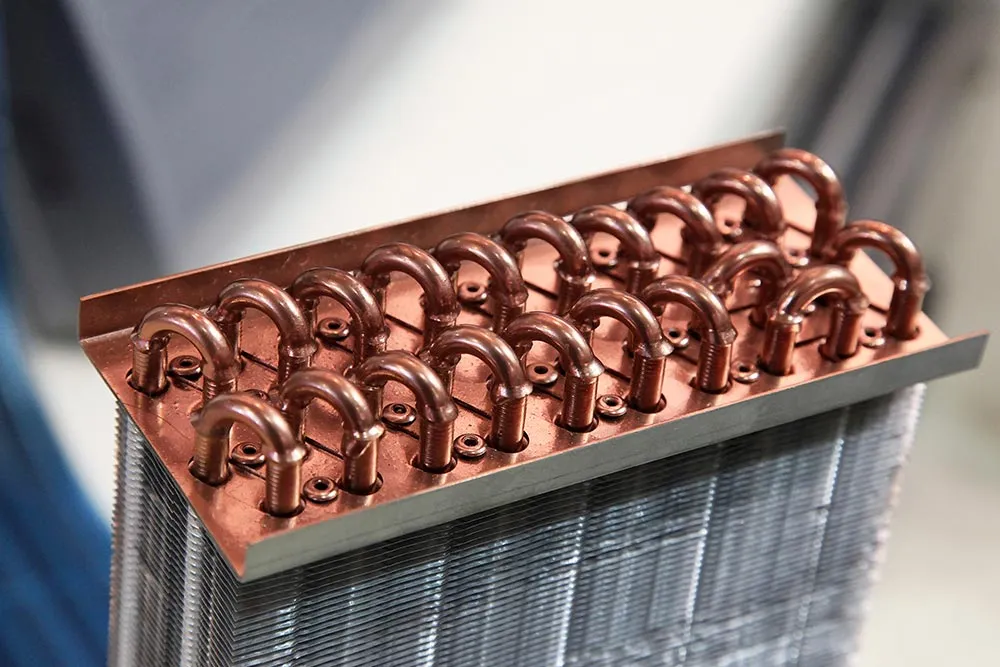

Stainless heat exchanger tubes are precision-engineered seamless or welded components designed for efficient thermal transfer in demanding environments, offering unmatched corrosion resistant exchanger pipes and boiler exchanger protection. Conforming to standards like ASTM A249, A213, and ASME SA249, common grades such as 304, 316, and 321 feature high chromium (16-20%) and nickel (8-14%) content to form a robust passive oxide layer, shielding against pitting, crevice corrosion, and stress cracking in aggressive media like seawater, chlorinated solvents, and acidic flue gases. These high temperature heat transfer tubing excels in shell-and-tube, plate, and finned configurations, supporting pressures up to 10 MPa and temperatures from -196°C to 800°C, making them indispensable for power generation, oil refining, and chemical processing where reliable erosion resistant stainless tubes prevent tube failures and optimize energy efficiency.

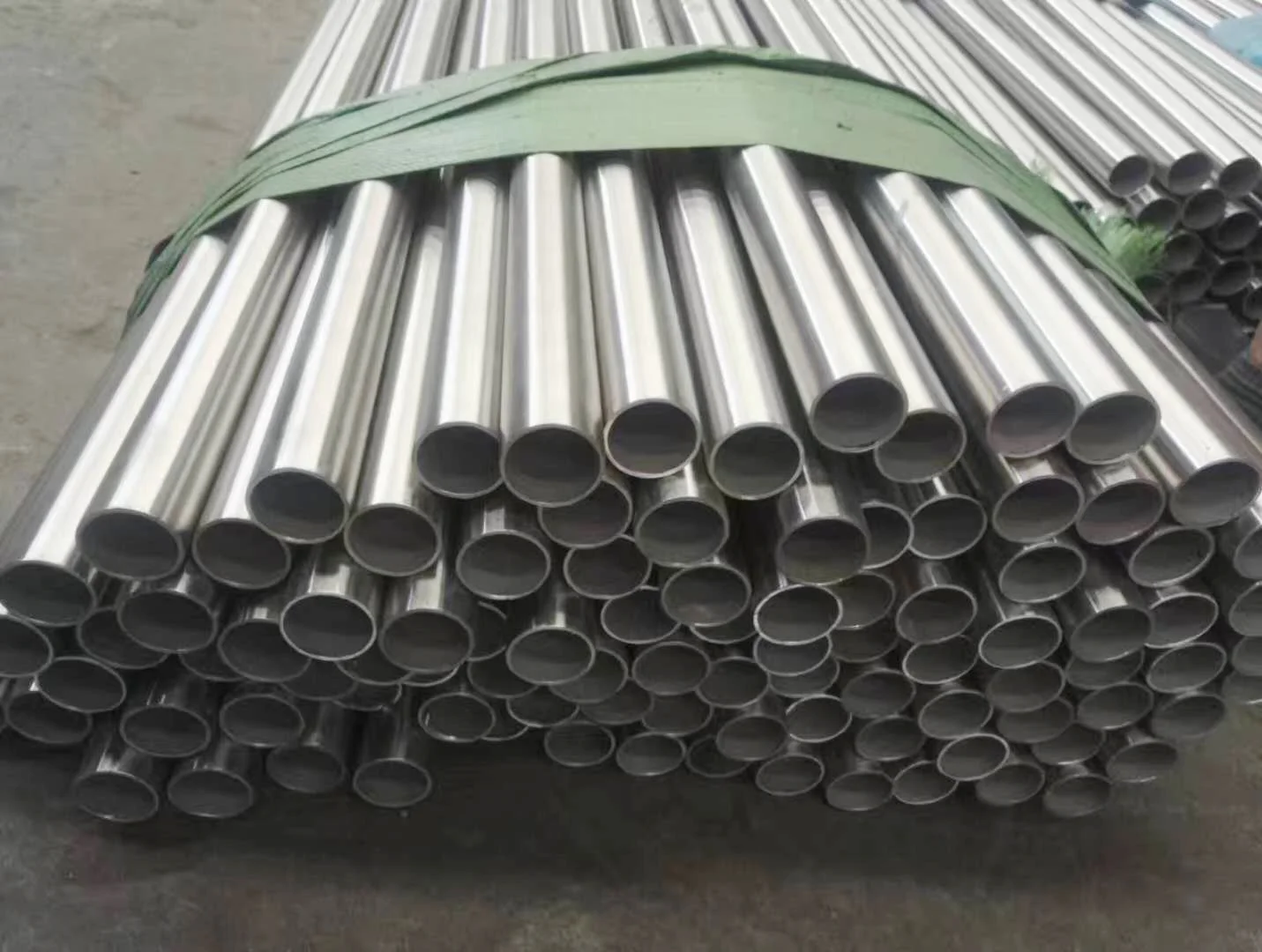

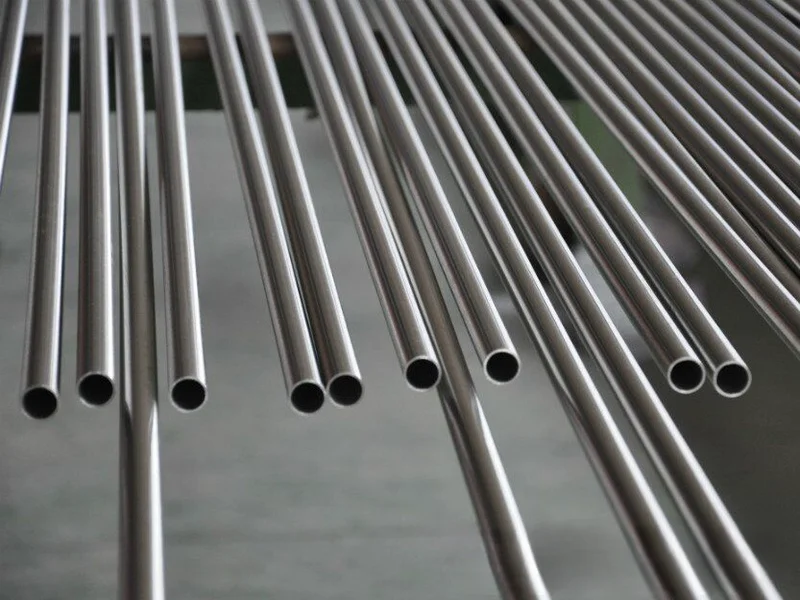

Produced via cold drawing or pilgering followed by bright annealing in controlled atmospheres, stainless heat exchanger tubes achieve superior surface finish (Ra high temperature heat transfer tubing. Low-carbon variants like 304L and 316L reduce carbide formation during welding, ensuring intergranular corrosion resistance without post-weld heat treatment, while stabilized grades such as 321 (titanium-added) and 347 (niobium-stabilized) avert sensitization in the 425-815°C range for prolonged exposure in furnace walls and economizers. Available in straight lengths up to 30m or U-bends with tight radii (1.5D), wall thicknesses from 0.5-5 mm, and outer diameters 6-50 mm, they accommodate diverse designs including enhanced surface textures for up to 30% improved heat transfer coefficients.

In boiler exchanger protection, these tubes mitigate steam-side erosion from high-velocity vapors and fireside scaling from sulfurous combustion, with 316 providing molybdenum-enhanced resistance to chloride pitting in coastal power plants. Hydrostatic testing to 1.5x design pressure, eddy current flaw detection, and flattening tests confirm integrity, delivering minimum tensile strengths of 485-620 MPa and yield strengths of 170-310 MPa for cyclic loading resilience. Optional features like finned extensions or internal rifling boost turbulence for better convective heat exchange, while electropolished interiors (Ra

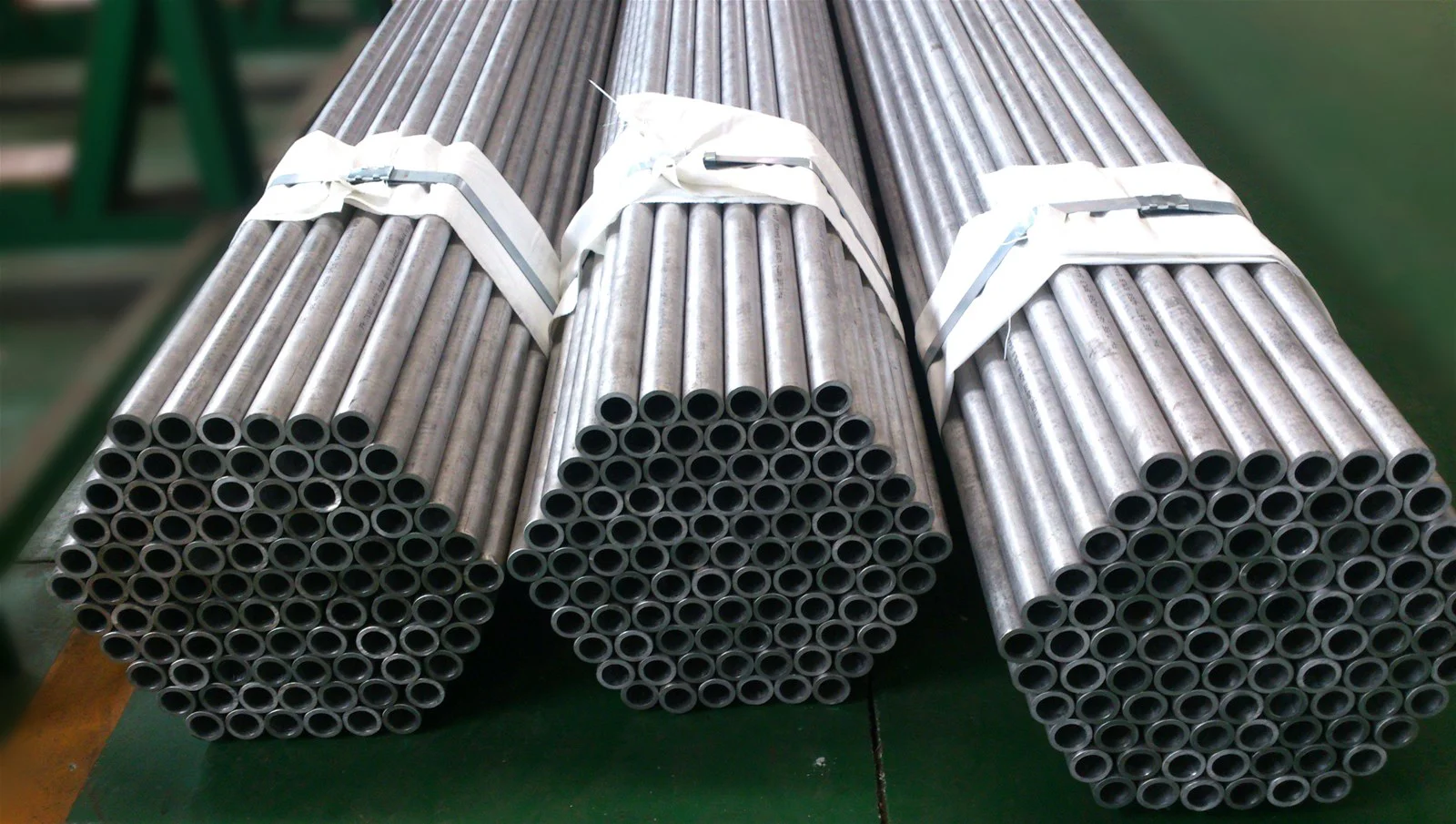

Compared to carbon steel alternatives, corrosion resistant exchanger pipes like 304 exhibit 5-10x longer lifespan in corrosive condensates, with lower thermal expansion (16.5 x 10^-6/°C) reducing thermal stress in fluctuating cycles common to erosion resistant stainless tubes. Duplex grades such as 2205 offer hybrid austenitic-ferritic benefits with doubled yield strength (450 MPa) for high-pressure offshore platforms, while their non-magnetic properties (μ

Tackling prevalent issues like tube plugging from fouling or localized corrosion in sour service, stainless heat exchanger tubes reduce downtime by 40-60% through enhanced fouling resistance and self-passivating surfaces, aligning with API 660 guidelines for sustainable operations. Whether for high temperature heat transfer tubing in gas coolers or general boiler exchanger protection in HVAC systems, these tubes provide a cost-effective, high-reliability option, ensuring seamless integration and peak performance in oil & gas, energy, and biotechnology sectors.

Stainless heat exchanger tubes application

Stainless steel heat exchanger tubes are supplied to a wide range of industries including petrochemical, power generation, pulp/paper, and chemical processing. They are suitable for all types of heat exchangers, such as seawater coolers, condensers, evaporators, heaters, and reheaters.

| Grade | C | Mn | Si | P | S | Cr | Ni | Others |

|---|---|---|---|---|---|---|---|---|

| 304 | 0.08 | 2.00 | 0.75 | 0.045 | 0.030 | 18.0-20.0 | 8.0-10.5 | N: 0.10 |

| 316 | 0.08 | 2.00 | 0.75 | 0.045 | 0.030 | 16.0-18.0 | 10.0-14.0 | Mo: 2.0-3.0 |

| 321 | 0.08 | 2.00 | 0.75 | 0.045 | 0.030 | 17.0-19.0 | 9.0-12.0 | Ti: 5xC min |

| 2205 (Duplex) | 0.03 | 2.00 | 1.00 | 0.030 | 0.020 | 22.0-23.0 | 4.5-6.5 | Mo: 3.0-3.5; N: 0.14-0.20 |

| Grade | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Hardness (HB max) |

|---|---|---|---|---|

| 304 | 515 | 205 | 40 | 201 |

| 316 | 515 | 205 | 40 | 217 |

| 321 | 515 | 205 | 40 | 217 |

| 2205 | 620 | 450 | 25 | 293 |

| Feature | 304 | 316 | 321 | 2205 (Duplex) |

|---|---|---|---|---|

| Corrosion Resistance | Good | Excellent (Mo) | Good (Stabilized) | Superior (Cl Resistance) |

| Max Temp (°C) | 800 | 800 | 815 | 300 |

| Thermal Conductivity (W/m·K) | 16.2 | 15.2 | 16.1 | 15.0 |

| Cost | Low | Medium | Medium | High |

| Applications | General Exchangers | Marine, Chemical | High-Temp Welded | Offshore, Sour Service |

| Tensile Strength (MPa) | 515 min | 515 min | 515 min | 620 min |

| Key Advantage | Versatility | Pitting Resistance | Anti-Sensitization | High Strength |

We stock stainless steels in a multitude of shapes and sizes.

We support our stainless steel stock with a wide range of shapes and sizes to suit your engineering applications. We hold thirteen different types of shapes to support the grades of material we stock, including bars, sheets and plates.

Stainless Carbon Steel Composite Pipe

Sort:99

Material-Specific Erosion Shields

Sort:99

| Grade | C (% max) | Mn (% max) | Si (% max) | P (% max) | S (% max) | Cr (%) | Ni (%) | Mo (%) | N (% max) |

|---|---|---|---|---|---|---|---|---|---|

| 304 | 0.08 | 2.00 | 1.00 | 0.045 | 0.030 | 18.0-20.0 | 8.0-11.0 | - | 0.10 |

| 304L | 0.03 | 2.00 | 1.00 | 0.045 | 0.030 | 18.0-20.0 | 8.0-12.0 | - | 0.10 |

| 316 | 0.08 | 2.00 | 1.00 | 0.045 | 0.030 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 | 0.10 |

| 316L | 0.03 | 2.00 | 1.00 | 0.045 | 0.030 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 | 0.10 |

The low carbon content in 304L and 316L enhances weldability, while molybdenum in 316 and 316L improves resistance to pitting and crevice corrosion, making Stainless heat exchanger tube ideal for harsh environments.

| Grade | Tensile Strength (min, MPa) | Yield Strength (min, MPa) | Elongation (min, %) | Hardness (max, HB) | Hardness (max, HRB) |

|---|---|---|---|---|---|

| 304 | 515 | 205 | 40 | 201 | 92 |

| 304L | 485 | 170 | 40 | 201 | 92 |

| 316 | 515 | 205 | 40 | 217 | 95 |

| 316L | 485 | 170 | 40 | 217 | 95 |

These mechanical properties make Stainless heat exchanger tube suitable for applications requiring high strength and corrosion resistance, such as architectural structures, marine environments, and chemical processing.

In order to solve the cumbersome and difficult to remember stainless steel grades, improve the practicability of the brand representation, and the contrast with the international standard grades, China has formulated the "Universal Code System for Steel and Alloy Grades", such as 06Cr19Ni10, corresponding to 304. Different grades of stainless steel have different ingredients, but they all have a national standard. The standards of each country are also different.

| No | China (GB) | Japan (JIS) | American | Korea (KS) | EU (BS EN) | India (IS) | Australia (AS) | Taiwan (CNS) | ||

|---|---|---|---|---|---|---|---|---|---|---|

| Old | New (07.10) | SUS | ASTM | UNS | STS | EN | IS | AS | CNS | |

| Austenitic Stainless Steel | ||||||||||

| 1 | 1Cr17Mn6Ni5N | 12Cr17Mn6Ni5N | SUS201 | 201 | S20100 | STS201 | 1.4372 | 10Cr17Mn6Ni4N20 | 201-2 | 201 |

| 2 | 1Cr18Mn8Ni5N | 12Cr18Mn9Ni5N | SUS202 | 202 | S20200 | STS202 | 1.4373 | — | — | 202 |

| 3 | 1Cr17Ni7 | 12Cr17Ni7 | SUS301 | 301 | S30100 | STS301 | 1.4319 | 10Cr17Ni7 | 301 | 301 |

| 4 | 0Cr18Ni9 | 06Cr19Ni10 | SUS304 | 304 | S30400 | STS304 | 1.4301 | 07Cr18Ni9 | 304 | 304 |

| 5 | 00Cr19Ni10 | 022Cr19Ni10 | SUS304L | 304L | S30403 | STS304L | 1.4306 | 02Cr18Ni11 | 304L | 304L |

| 6 | 0Cr19Ni9N | 06Cr19Ni10N | SUS304N1 | 304N | S30451 | STS304N1 | 1.4315 | — | 304N1 | 304N1 |

| 7 | 0Cr19Ni10NbN | 06Cr19Ni9NbN | SUS304N2 | XM21 | S30452 | STS304N2 | — | — | 304N2 | 304N2 |

| 8 | 00Cr18Ni10N | 022Cr19Ni10N | SUS304LN | 304LN | S30453 | STS304LN | — | — | 304LN | 304LN |

| 9 | 1Cr18Ni12 | 10Cr18Ni12 | SUS305 | 305 | S30500 | STS305 | 1.4303 | — | 305 | 305 |

| 10 | 0Cr23Ni13 | 06Cr23Ni13 | SUS309S | 309S | S30908 | STS309S | 1.4833 | — | 309S | 309S |

| 11 | 0Cr25Ni20 | 06Cr25Ni20 | SUS310S | 310S | S31008 | STS310S | 1.4845 | — | 310S | 310S |

| 12 | 0Cr17Ni12Mo2 | 06Cr17Ni12Mo2 | SUS316 | 316 | S31600 | STS316 | 1.4401 | 04Cr17Ni12Mo2 | 316 | 316 |

| 13 | 0Cr18Ni12Mo3Ti | 06Cr17Ni12Mo2Ti | SUS316Ti | 316Ti | S31635 | — | 1.4571 | 04Cr17Ni12MoTi20 | 316Ti | 316Ti |

| 14 | 00Cr17Ni14Mo2 | 022Cr17Ni12Mo2 | SUS316L | 316L | S31603 | STS316L | 1.4404 | 02Cr17Ni12Mo2 | 316L | 316L |

| 15 | 0Cr17Ni12Mo2N | 06Cr17Ni12Mo2N | SUS316N | 316N | S31651 | STS316N | — | — | 316N | 316N |

| 16 | 00Cr17Ni13Mo2N | 022Cr17Ni13Mo2N | SUS316LN | 316LN | S31653 | STS316LN | 1.4429 | — | 316LN | 316LN |

| 17 | 0Cr18Ni12Mo2Cu2 | 06Cr18Ni12Mo2Cu2 | SUS316J1 | — | — | STS316J1 | — | — | 316J1 | 316J1 |

| 18 | 00Cr18Ni14Mo2Cu2 | 022Cr18Ni14Mo2Cu2 | SUS316J1L | — | — | STS316J1L | — | — | — | 316J1L |

| 19 | 0Cr19Ni13Mo3 | 06Cr19Ni13Mo3 | SUS317 | 317 | S31700 | STS317 | — | — | 317 | 317 |

| 20 | 00Cr19Ni13Mo3 | 022Cr19Ni13Mo3 | SUS317L | 317L | S31703 | STS317L | 1.4438 | — | 317L | 317L |

| 21 | 0Cr18Ni10Ti | 06Cr18Ni11Ti | SUS321 | 321 | S32100 | STS321 | 1.4541 | 04Cr18Ni10Ti20 | 321 | 321 |

| 22 | 0Cr18Ni11Nb | 06Cr18Ni11Nb | SUS347 | 347 | S34700 | STS347 | 1.4550 | 04Cr18Ni10Nb40 | 347 | 347 |

| Austenitic-Ferritic Stainless Steel (Duplex) | ||||||||||

| 23 | 0Cr26Ni5Mo2 | — | SUS329J1 | 329 | S32900 | STS329J1 | 1.4477 | — | 329J1 | 329J1 |

| 24 | 00Cr18Ni5Mo3Si2 | 022Cr19Ni5Mo3Si2N | SUS329J3L | — | S31803 | STS329J3L | 1.4462 | — | 329J3L | 329J3L |

| Ferritic Stainless Steel | ||||||||||

| 25 | 0Cr13Al | 06Cr13Al | SUS405 | 405 | S40500 | STS405 | 1.4002 | 04Cr13 | 405 | 405 |

| 26 | — | 022Cr11Ti | SUH409 | 409 | S40900 | STS409 | 1.4512 | — | 409L | 409L |

| 27 | 00Cr12 | 022Cr12 | SUS410L | — | — | STS410L | — | — | 410L | 410L |

| 28 | 1Cr17 | 10Cr17 | SUS430 | 430 | S43000 | STS430 | 1.4016 | 05Cr17 | 430 | 430 |

| 29 | 1Cr17Mo | 10Cr17Mo | SUS434 | 434 | S43400 | STS434 | 1.4113 | — | 434 | 434 |

| 30 | — | 022Cr18NbTi | — | — | S43940 | — | 1.4509 | — | 439 | 439 |

| 31 | 00Cr18Mo2 | 019Cr19Mo2NbTi | SUS444 | 444 | S44400 | STS444 | 1.4521 | — | 444 | 444 |

| Martensitic Stainless Steel | ||||||||||

| 32 | 1Cr12 | 12Cr12 | SUS403 | 403 | S40300 | STS403 | — | — | 403 | 403 |

| 33 | 1Cr13 | 12Cr13 | SUS410 | 410 | S41000 | STS410 | 1.4006 | 12Cr13 | 410 | 410 |

| 34 | 2Cr13 | 20Cr13 | SUS420J1 | 420 | S42000 | STS420J1 | 1.4021 | 20Cr13 | 420 | 420J1 |

| 35 | 3Cr13 | 30Cr13 | SUS420J2 | — | — | STS420J2 | 1.4028 | 30Cr13 | 420J2 | 420J2 |

| 36 | 7Cr17 | 68Cr17 | SUS440A | 440A | S44002 | STS440A | — | — | 440A | 440A |

Seamless pipes are critical in various industries thanks to their excellent strength, temperature resistance, and structural uniformity. They ensure safe and efficient performance in demanding environments.

Used in steam pipelines, boiler tubes, superheaters, and heat exchangers for high-temperature and high-pressure conditions in power plants.

Transports crude oil, natural gas, and petroleum products in pipelines and refinery units, handling high-pressure and corrosion.

Handles chemicals, gases, and hazardous substances in reactors and heat exchangers, ensuring safe processing.

Applied in automotive systems and machinery for fluid conveyance and precision components requiring strength and accuracy.

Used in structural support, water and sewage systems, and building frameworks for strength and corrosion resistance.

Utilized in hydraulic and engine systems onboard, resisting corrosion in marine environments.

Employed in aircraft and military equipment for hydraulic systems and structural components.

Stainless pipes for hygienic transport of food and pharmaceutical products, maintaining sterility.

Designed for transporting slurries and chemicals in mining, withstanding abrasion and harsh conditions.

Ferritic stainless steel tubes

Sort:0

Customized Alumina Ceramic Lined Project

Sort:99

High Chromium Alloy Lined Pipe

Sort:99

Sort:0

Wear-Resistant Hardfacing Liner Plate

Sort:0