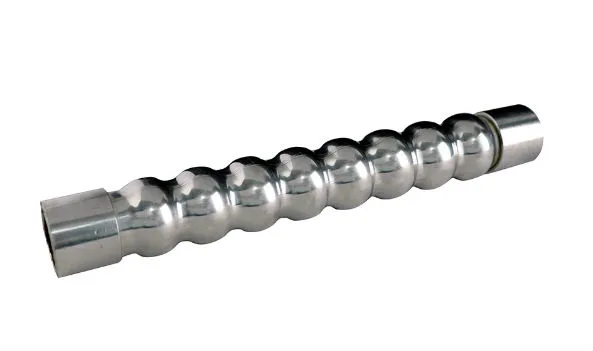

Stainless steel corrugated tube is usually used in heat exchange equipment.

Stainless steel corrugated tube is usually used in heat exchange equipment.

Stainless steel corrugated tubes are specialized flexible components engineered for high-pressure and high-temperature applications, delivering robust corrosion resistant flexible pipes in dynamic industrial environments. Formed by helically or annularly corrugating seamless or welded base tubes, these products provide exceptional axial elongation, compression, and angular deflection capabilities, making them indispensable for expansion joints, metal hoses, and vibration isolators. Primarily constructed from austenitic grades like 304L, 316L, and 321, they conform to ASTM A312, ASME B31.3, and EJMA standards, offering superior resistance to pitting, crevice corrosion, and fatigue in aggressive conditions such as seawater, acids, and high-velocity fluids. Ideal for high pressure corrugated hoses in petrochemical transfer lines and marine exhaust systems, these tubes withstand pressures up to 100 bar and temperatures from -200°C to 600°C, preventing leaks and structural failures in rigid piping setups.

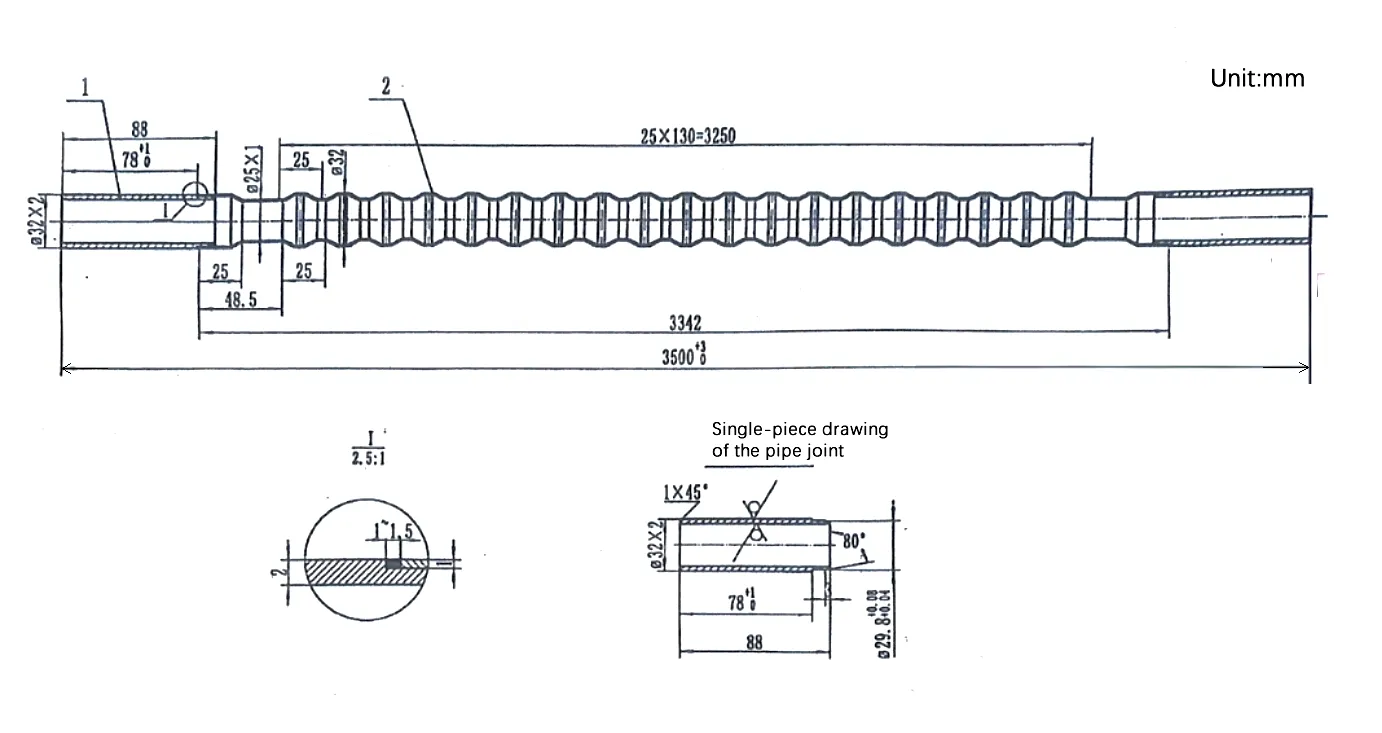

The corrugation process, achieved through hydraulic forming or rotary rolling on parent tubes with 0.5-3mm wall thicknesses, enhances flexibility without sacrificing the alloy's inherent corrosion resistance, with 316L variants featuring 2-3% molybdenum for enhanced performance in chloride-rich settings like desalination plants. Low-carbon formulations (boiler expansion tubing. Available in nominal diameters from 1/4" to 12" (6-300mm), with convolution pitches of 8-20mm and heights of 3-10mm, these tubes accommodate custom designs including braided reinforcements for burst protection and flanged ends for straightforward integration into industrial corrugated steel pipes assemblies, ensuring compliance with API 661 for air-cooled heat exchangers.

In vibration-intensive applications, such as pump discharges or compressor hoses, the corrugated geometry absorbs axial, lateral, and angular movements up to 30° while resisting erosion from abrasive slurries, with finishes ranging from mill to electropolished (Ra corrosion resistant flexible pipes must endure H2S and CO2 per NACE MR0175.

Relative to copper or carbon steel options, stainless steel corrugated tubes achieve 5-10x extended service life in corrosive atmospheres thanks to their self-passivating chromium oxide layer, featuring lower thermal expansion (16-18 x 10^-6/°C) to lessen stress in fluctuating boiler operations. Duplex grades like 2205 furnish hybrid strength for high-pressure subsea hoses, but austenitic prevalence in flexibility favors them for high pressure corrugated hoses in automotive exhausts and aerospace ducts. Their recyclability (up to 95%) and non-magnetic attributes (permeability

Confronting critical issues like thermal fatigue in expansion loops or chloride pitting in coastal setups, these tubes diminish unplanned downtime by 50-70% via innate vibration damping and erosion barriers, adhering to ASME Section VIII for pressure vessels. Whether utilized for boiler expansion tubing in power generation or versatile industrial corrugated steel pipes in mining slurry lines, stainless steel corrugated tubes furnish adaptable, resilient operation with validated success across worldwide severe-duty industries, enabling engineers to craft more secure and effective systems.

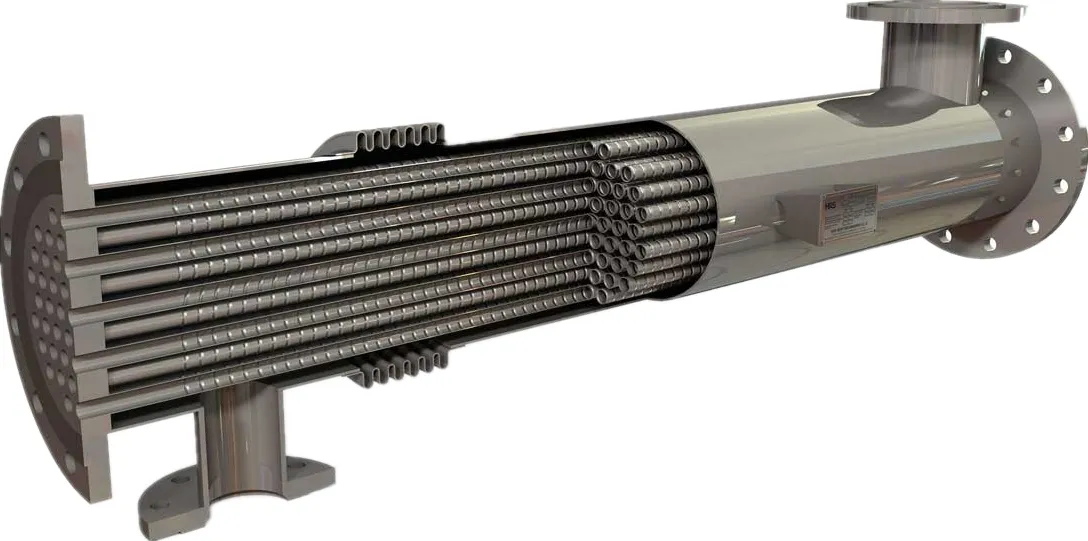

Compared with ordinary seamless steel pipes, stainless steel corrugated tubes offer a larger heat exchange area, smaller tube wall thermal resistance, and excellent heat transfer coefficients. This makes them an innovative, high-efficiency heat exchange solution that has been widely adopted in heat exchange equipment as a replacement for traditional tubes.

Heat exchanger stainless steel corrugated tubes are thin-walled tubes with continuously tangent large and small arcs forming internal and external corrugations. This design creates three-dimensional fluid movement, resulting in intense turbulence even at low flow rates. The thin tube wall minimizes temperature gradients, significantly reducing thermal resistance and improving overall heat transfer efficiency.

Stainless steel corrugated tubes are renowned for their flexibility, durability, and resistance to high temperatures. They are commonly utilized in heating systems, air conditioning, solar technology, and various applications requiring reliable, versatile piping solutions.

Typically manufactured from 1.4301, 1.4404, or 1.4571 grades, offering excellent corrosion resistance and mechanical properties suitable for diverse environments.

Available with nominal diameters ranging from DN12 to DN50. Lengths can be customized according to specific project requirements.

| Grade | C | Mn | Si | P | S | Cr | Ni | Others |

|---|---|---|---|---|---|---|---|---|

| 304L | 0.03 | 2.00 | 0.75 | 0.045 | 0.030 | 18.0-20.0 | 8.0-12.0 | N: 0.10 |

| 316L | 0.03 | 2.00 | 0.75 | 0.045 | 0.030 | 16.0-18.0 | 10.0-14.0 | Mo: 2.0-3.0 |

| 321 | 0.08 | 2.00 | 0.75 | 0.045 | 0.030 | 17.0-19.0 | 9.0-12.0 | Ti: 5xC min |

| 310S | 0.08 | 2.00 | 1.50 | 0.045 | 0.030 | 24.0-26.0 | 19.0-22.0 | - |

| Grade | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Hardness (HB max) |

|---|---|---|---|---|

| 304L | 485 | 170 | 40 | 201 |

| 316L | 485 | 170 | 40 | 217 |

| 321 | 515 | 205 | 40 | 217 |

| 310S | 515 | 205 | 40 | 217 |

| Nominal Bore (NB) (mm) |

Min. Radius Bend | Without Braid | Single Braid | Double Braid | ||||

|---|---|---|---|---|---|---|---|---|

| Static (mm) | Flexing (mm) | Maximum Pressure Kg/cm2 |

Test Pressure Kg/cm2 |

Maximum Pressure Kg/cm2 |

Test Pressure Kg/cm2 |

Maximum Pressure Kg/cm2 |

Test Pressure Kg/cm2 |

|

| 6 | 25 | 100 | 4 | 6 | 100 | 150 | 160 | 240 |

| 10 | 40 | 150 | 4 | 6 | 90 | 135 | 144 | 216 |

| 12 | 50 | 200 | 3 | 4.5 | 80 | 120 | 128 | 192 |

| 16 | 50 | 200 | 3 | 4.5 | 70 | 105 | 112 | 168 |

| 20 | 70 | 200 | 2 | 3 | 64 | 96 | 102 | 153 |

| 25 | 90 | 200 | 2 | 3 | 50 | 75 | 80 | 120 |

| 32 | 110 | 250 | 1.5 | 2.3 | 40 | 60 | 64 | 96 |

| 40 | 130 | 250 | 1.5 | 2.3 | 30 | 45 | 48 | 92 |

| 50 | 175 | 350 | 1.0 | 1.5 | 28 | 42 | 44 | 66 |

| 65 | 200 | 410 | 1.0 | 1.5 | 24 | 36 | 38 | 57 |

| 80 | 205 | 450 | 1.0 | 1.5 | 18 | 27 | 28 | 42 |

| 100 | 230 | 560 | 0.8 | 1.2 | 16 | 24 | 26 | 39 |

| 125 | 280 | 660 | 0.6 | 0.9 | 12 | 18 | 20 | 30 |

| 150 | 320 | 816 | 0.6 | 0.9 | 10 | 15 | 16 | 24 |

| 200 | 435 | 1015 | 0.5 | 0.75 | 8 | 12 | 12 | 18 |

Stainless steel corrugated tubes for heat exchangers are widely used in petroleum, chemical industry, power systems, and heating applications.

We stock stainless steels in a multitude of shapes and sizes.

We support our stainless steel stock with a wide range of shapes and sizes to suit your engineering applications. We hold thirteen different types of shapes to support the grades of material we stock, including bars, sheets and plates.

Stainless Carbon Steel Composite Pipe

Sort:99

Material-Specific Erosion Shields

Sort:99

| Grade | C (% max) | Mn (% max) | Si (% max) | P (% max) | S (% max) | Cr (%) | Ni (%) | Mo (%) | N (% max) |

|---|---|---|---|---|---|---|---|---|---|

| 304 | 0.08 | 2.00 | 1.00 | 0.045 | 0.030 | 18.0-20.0 | 8.0-11.0 | - | 0.10 |

| 304L | 0.03 | 2.00 | 1.00 | 0.045 | 0.030 | 18.0-20.0 | 8.0-12.0 | - | 0.10 |

| 316 | 0.08 | 2.00 | 1.00 | 0.045 | 0.030 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 | 0.10 |

| 316L | 0.03 | 2.00 | 1.00 | 0.045 | 0.030 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 | 0.10 |

The low carbon content in 304L and 316L enhances weldability, while molybdenum in 316 and 316L improves resistance to pitting and crevice corrosion, making Stainless steel corrugated tube ideal for harsh environments.

| Grade | Tensile Strength (min, MPa) | Yield Strength (min, MPa) | Elongation (min, %) | Hardness (max, HB) | Hardness (max, HRB) |

|---|---|---|---|---|---|

| 304 | 515 | 205 | 40 | 201 | 92 |

| 304L | 485 | 170 | 40 | 201 | 92 |

| 316 | 515 | 205 | 40 | 217 | 95 |

| 316L | 485 | 170 | 40 | 217 | 95 |

These mechanical properties make Stainless steel corrugated tube suitable for applications requiring high strength and corrosion resistance, such as architectural structures, marine environments, and chemical processing.

In order to solve the cumbersome and difficult to remember stainless steel grades, improve the practicability of the brand representation, and the contrast with the international standard grades, China has formulated the "Universal Code System for Steel and Alloy Grades", such as 06Cr19Ni10, corresponding to 304. Different grades of stainless steel have different ingredients, but they all have a national standard. The standards of each country are also different.

| No | China (GB) | Japan (JIS) | American | Korea (KS) | EU (BS EN) | India (IS) | Australia (AS) | Taiwan (CNS) | ||

|---|---|---|---|---|---|---|---|---|---|---|

| Old | New (07.10) | SUS | ASTM | UNS | STS | EN | IS | AS | CNS | |

| Austenitic Stainless Steel | ||||||||||

| 1 | 1Cr17Mn6Ni5N | 12Cr17Mn6Ni5N | SUS201 | 201 | S20100 | STS201 | 1.4372 | 10Cr17Mn6Ni4N20 | 201-2 | 201 |

| 2 | 1Cr18Mn8Ni5N | 12Cr18Mn9Ni5N | SUS202 | 202 | S20200 | STS202 | 1.4373 | — | — | 202 |

| 3 | 1Cr17Ni7 | 12Cr17Ni7 | SUS301 | 301 | S30100 | STS301 | 1.4319 | 10Cr17Ni7 | 301 | 301 |

| 4 | 0Cr18Ni9 | 06Cr19Ni10 | SUS304 | 304 | S30400 | STS304 | 1.4301 | 07Cr18Ni9 | 304 | 304 |

| 5 | 00Cr19Ni10 | 022Cr19Ni10 | SUS304L | 304L | S30403 | STS304L | 1.4306 | 02Cr18Ni11 | 304L | 304L |

| 6 | 0Cr19Ni9N | 06Cr19Ni10N | SUS304N1 | 304N | S30451 | STS304N1 | 1.4315 | — | 304N1 | 304N1 |

| 7 | 0Cr19Ni10NbN | 06Cr19Ni9NbN | SUS304N2 | XM21 | S30452 | STS304N2 | — | — | 304N2 | 304N2 |

| 8 | 00Cr18Ni10N | 022Cr19Ni10N | SUS304LN | 304LN | S30453 | STS304LN | — | — | 304LN | 304LN |

| 9 | 1Cr18Ni12 | 10Cr18Ni12 | SUS305 | 305 | S30500 | STS305 | 1.4303 | — | 305 | 305 |

| 10 | 0Cr23Ni13 | 06Cr23Ni13 | SUS309S | 309S | S30908 | STS309S | 1.4833 | — | 309S | 309S |

| 11 | 0Cr25Ni20 | 06Cr25Ni20 | SUS310S | 310S | S31008 | STS310S | 1.4845 | — | 310S | 310S |

| 12 | 0Cr17Ni12Mo2 | 06Cr17Ni12Mo2 | SUS316 | 316 | S31600 | STS316 | 1.4401 | 04Cr17Ni12Mo2 | 316 | 316 |

| 13 | 0Cr18Ni12Mo3Ti | 06Cr17Ni12Mo2Ti | SUS316Ti | 316Ti | S31635 | — | 1.4571 | 04Cr17Ni12MoTi20 | 316Ti | 316Ti |

| 14 | 00Cr17Ni14Mo2 | 022Cr17Ni12Mo2 | SUS316L | 316L | S31603 | STS316L | 1.4404 | 02Cr17Ni12Mo2 | 316L | 316L |

| 15 | 0Cr17Ni12Mo2N | 06Cr17Ni12Mo2N | SUS316N | 316N | S31651 | STS316N | — | — | 316N | 316N |

| 16 | 00Cr17Ni13Mo2N | 022Cr17Ni13Mo2N | SUS316LN | 316LN | S31653 | STS316LN | 1.4429 | — | 316LN | 316LN |

| 17 | 0Cr18Ni12Mo2Cu2 | 06Cr18Ni12Mo2Cu2 | SUS316J1 | — | — | STS316J1 | — | — | 316J1 | 316J1 |

| 18 | 00Cr18Ni14Mo2Cu2 | 022Cr18Ni14Mo2Cu2 | SUS316J1L | — | — | STS316J1L | — | — | — | 316J1L |

| 19 | 0Cr19Ni13Mo3 | 06Cr19Ni13Mo3 | SUS317 | 317 | S31700 | STS317 | — | — | 317 | 317 |

| 20 | 00Cr19Ni13Mo3 | 022Cr19Ni13Mo3 | SUS317L | 317L | S31703 | STS317L | 1.4438 | — | 317L | 317L |

| 21 | 0Cr18Ni10Ti | 06Cr18Ni11Ti | SUS321 | 321 | S32100 | STS321 | 1.4541 | 04Cr18Ni10Ti20 | 321 | 321 |

| 22 | 0Cr18Ni11Nb | 06Cr18Ni11Nb | SUS347 | 347 | S34700 | STS347 | 1.4550 | 04Cr18Ni10Nb40 | 347 | 347 |

| Austenitic-Ferritic Stainless Steel (Duplex) | ||||||||||

| 23 | 0Cr26Ni5Mo2 | — | SUS329J1 | 329 | S32900 | STS329J1 | 1.4477 | — | 329J1 | 329J1 |

| 24 | 00Cr18Ni5Mo3Si2 | 022Cr19Ni5Mo3Si2N | SUS329J3L | — | S31803 | STS329J3L | 1.4462 | — | 329J3L | 329J3L |

| Ferritic Stainless Steel | ||||||||||

| 25 | 0Cr13Al | 06Cr13Al | SUS405 | 405 | S40500 | STS405 | 1.4002 | 04Cr13 | 405 | 405 |

| 26 | — | 022Cr11Ti | SUH409 | 409 | S40900 | STS409 | 1.4512 | — | 409L | 409L |

| 27 | 00Cr12 | 022Cr12 | SUS410L | — | — | STS410L | — | — | 410L | 410L |

| 28 | 1Cr17 | 10Cr17 | SUS430 | 430 | S43000 | STS430 | 1.4016 | 05Cr17 | 430 | 430 |

| 29 | 1Cr17Mo | 10Cr17Mo | SUS434 | 434 | S43400 | STS434 | 1.4113 | — | 434 | 434 |

| 30 | — | 022Cr18NbTi | — | — | S43940 | — | 1.4509 | — | 439 | 439 |

| 31 | 00Cr18Mo2 | 019Cr19Mo2NbTi | SUS444 | 444 | S44400 | STS444 | 1.4521 | — | 444 | 444 |

| Martensitic Stainless Steel | ||||||||||

| 32 | 1Cr12 | 12Cr12 | SUS403 | 403 | S40300 | STS403 | — | — | 403 | 403 |

| 33 | 1Cr13 | 12Cr13 | SUS410 | 410 | S41000 | STS410 | 1.4006 | 12Cr13 | 410 | 410 |

| 34 | 2Cr13 | 20Cr13 | SUS420J1 | 420 | S42000 | STS420J1 | 1.4021 | 20Cr13 | 420 | 420J1 |

| 35 | 3Cr13 | 30Cr13 | SUS420J2 | — | — | STS420J2 | 1.4028 | 30Cr13 | 420J2 | 420J2 |

| 36 | 7Cr17 | 68Cr17 | SUS440A | 440A | S44002 | STS440A | — | — | 440A | 440A |

Seamless pipes are critical in various industries thanks to their excellent strength, temperature resistance, and structural uniformity. They ensure safe and efficient performance in demanding environments.

Used in steam pipelines, boiler tubes, superheaters, and heat exchangers for high-temperature and high-pressure conditions in power plants.

Transports crude oil, natural gas, and petroleum products in pipelines and refinery units, handling high-pressure and corrosion.

Handles chemicals, gases, and hazardous substances in reactors and heat exchangers, ensuring safe processing.

Applied in automotive systems and machinery for fluid conveyance and precision components requiring strength and accuracy.

Used in structural support, water and sewage systems, and building frameworks for strength and corrosion resistance.

Utilized in hydraulic and engine systems onboard, resisting corrosion in marine environments.

Employed in aircraft and military equipment for hydraulic systems and structural components.

Stainless pipes for hygienic transport of food and pharmaceutical products, maintaining sterility.

Designed for transporting slurries and chemicals in mining, withstanding abrasion and harsh conditions.

Ferritic stainless steel tubes

Sort:0

Customized Alumina Ceramic Lined Project

Sort:99

High Chromium Alloy Lined Pipe

Sort:99

Sort:0

Wear-Resistant Hardfacing Liner Plate

Sort:0